Designing a material handling solution requiring precise positioning can be challenging. There are many requirements you need to be aware of to create the solution that fits your needs. As you start looking for a solution to meet your needs, you’ll find there are many available so defining your unique requirements is a critical first step.

Defining your process and your requirements will include details like how many and how accurate the start/ stop points need to be, how quickly the component must travel between stopping points, and looking at your preferred maintenance process. Within your material handling solution, there will always be the AC motor and gearbox that will create the movement. When it comes down to it, the motor and gearbox is what tailors the inertia and speed to create the precision needed. There are 2 ways to accomplish this precision, electrically and mechanically. Each methodology can meet unique requirements of your project.

Electronic vs Mechanical Positioning

The most common way to accomplish precise positioning is to use an inverter with the AC induction motor. This is electronic braking. The inverter is programmed to the requirements of the project. Though this solution is commonly found from a variety of manufacturers, it can have its challenges from a maintenance perspective. The person doing maintenance will need the programming skills to do the job. In addition, the electrical components may not match the needs of a challenging or harsh environment.

The other alternative is mechanically achieving the positioning you require. Using a conical rotor motor combination accomplishes precise stopping points mechanically. Since there are no electronics, this solution fits a variety of harsh, extreme environments that an inverter solution may not be suited for. It can offer a wide range of speeds to tailor the inertia and speed to meet your positioning needs. Maintenance is easier since technicians don’t need to program anything and can use their trusty tools to accomplish the job.

The Basics of Precise Positioning with a Mechanical Solution

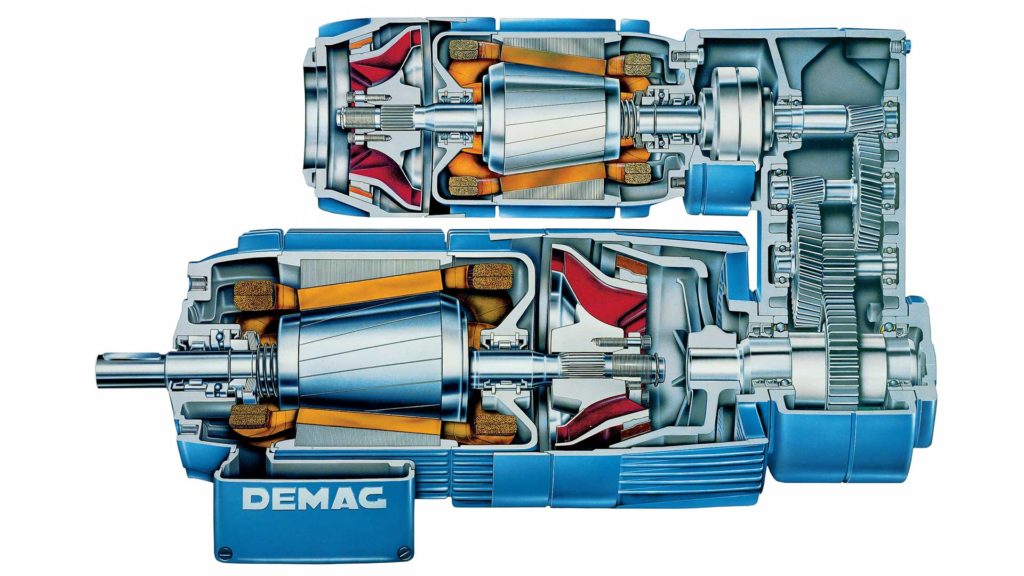

Conical rotor AC induction motors, also called squirrel cage motors, are used in applications where the positioning requirement must be mechanical. These motors have a cone shaped rotor and stator bore. This means when the motor is unenergized, the brake spring holds it in a braked position. It is a completely integral mechanical brake motor since there is no external brake module added to the motor. When energized, the cone shaped rotor is released from the braking surface, creating axial displacement and allowing the motor shaft to run at its normal speed.

Position accuracy is based on linear speed and inertia. The wider range of speed ratios available in a motor or motor combination will allow you to increase the precision of stopping and starting points. A motor with the ability to go slower has the ability to offer tighter, more accurate positioning than motors without this capability.

The Benefits of Mechanical Solutions

Mechanical solutions for material handling applications with precise positioning requirements have many benefits. In environments with high heat and moisture, caustic gasses, or high dust, many solutions are not designed to withstand the additional forces and environmental factors. Electrical components may have difficulty withstanding extreme environments. An example is a galvanizing plant where lifting equipment and material handling solutions must be designed to withstand a challenging environment with a high number of lifts for cranes or monorails.

Demag’s Mechanical Solution for Precise Positioning

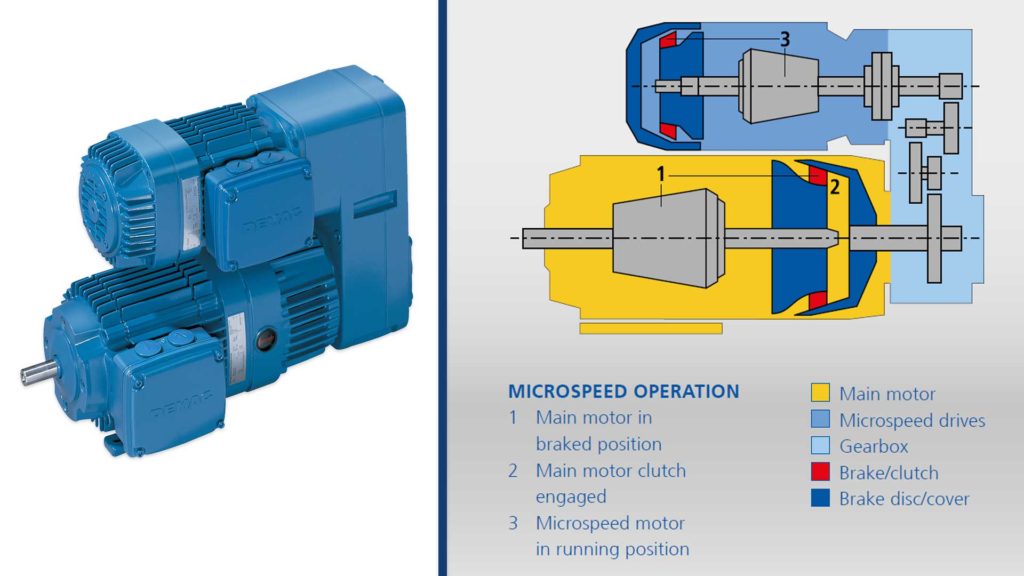

The Demag FG Microspeed motor combination consists of 2 brake motors and an intermediate reduction gearbox connecting them. One motor is a micro motor and the other is a larger, main motor. This combination creates a potential higher speed ratio than found in other motor applications. The precision comes from the microspeed motor and the reduction of the effective load inertia. In addition, as your number of starts per hour requirement increases, the micro motor allows for higher duty applications since the load is shared between the 2 unique motors.

In the FG Microspeed motor combination, the output shaft will run at the speed of either motor depending on which motor is energized. The intermediate gearbox reduces the rotational speed by the factor of the gear ratio. This means when the microspeed motor is operating, the load travel speed will be much slower. Therefore, with the lower speeds, you are able to meet your positioning requirements.

How Does it Work with 2 Motors?

Since the output shaft will run at the speed of either motor, the two motors can be energized independently. When the main motor is energized, the microspeed motor is not and the motor shaft runs at the standard speed of the main motor. As the microspeed motor is energized and the main motor is switched off, the speed of the micro motor is reduced by the intermediate gear according to its gear ratio. The output is transmitted through the main motor shaft through the main motor brake which acts like a clutch.

Common Applications of the Demag FG Microspeed Motor Combination

The FG Microspeed motor combination is a proven, flexible product. It meets the requirements of many applications where braking, positioning, eliminating overruns, and emergency braking is necessary. This combination is perfect for applications where precise lifting and/or positioning is needed for manufacturing operations.

The FG motor combination has been proven in uses in open winch applications, stacker cranes, inclined belt conveyors, tippers, fire doors on industrial furnaces, plate shearers, and folding machines. It fits the needs of a higher number of lifts/ starts per hour, therefore commonly meeting the duty factor of these applications. Also, variable speed lifting and crane drive is a common request. In contactor controlled crane and hoist applications, the FG microspeed combination can give a wide range of speeds similarly to traditional variable speed motors.

When the requirement is to eliminate time consuming overruns with rapid braking of masses, the FG microspeed combination can deliver. It can effectively drive lathe, milling and grinding spindles to eliminate overruns. In addition, balancing and drilling machines, pump drives, bucket scales, shakers and vibrators, and even industrial sliding doors can benefit from the elimination of overruns in your operations.

There are many industrial applications where repeated braking with precise angular positioning is critical. In many machines, like bending machines and multi-spindle tapping machines, positioning must be precise and the FG Microspeed can meet your demanding requirements. Racking and printing machines, valve control of hydraulic pumps, long band saws, and the table, carriage, and tool carrier drives of milling, grinding, and planning machines can benefit from this motor combination. In feeder applications, it’s necessary to have a precise stopping point for the loading and unloading points.

Safety is a critical factor in your manufacturing operations. The FG Microspeed combination can be used for emergency braking to prevent accidents or damage to materials. It can be designed to brake when there is trouble or inconsistencies in an application to avoid rejected product. Applications where this has been implemented include power looms, coiling and kneading machines, wire drawing equipment, paper, wood working, and wood veneer cutting machines.

Designing your material handling solution when precise positioning is needed can be challenging. The motor and gearbox are what tailors the inertia and speed to create the precision needed. Whether you use electronic or mechanical positioning, knowing your requirements and your process will assure you can find the solution you need. The Demag FG Microspeed motor combination gives you flexible mechanical positioning for your material handling project.

Reach out to our experts to discuss your needs!

Read more about co-axial F10 motors on the Demag DMR wire rope hoist. Need heavy lifting in an extreme environment or very precise lifting? Read more about the Demag DH wire rope hoist with co-axial F10 motors.