When you need to find a chain hoist solution for lifting your operations, the process can feel daunting. There are many options out there to research which takes time. This is why we’ve put together this Demag DC Chain Hoist Buyer’s Guide to help streamline some of the most common options available in our line of chain hoists. Read more about the product family features and what options may fit your application best.

The Demag DC Chain Hoist Product Family

Trusted for more than 20 years, the DC chain hoist line has been helping customers lift with greater safety, ergonomics, and reliability. Every model DC chain hoist offers standard features not found in other competitive chain hoists. In addition to the impressive list of standard features, we have the most options found anywhere, allowing DC chain hoists to meet almost any lifting requirement. Each DC chain hoist is designed to be rated to H4 heavy duty, or FEM 2M rating, so no matter your company size or budget, you know you are purchasing a quality product.

Safety As Standard

DC chain hoists are designed with safety features that come standard on all models. Each hoist is designed to use 24V control voltage for extremely safe operation. All models include an operating limit switch as standard for the highest and lowest hook position. A monitored slip clutch prevents serious overloads. These features work together to make lifting operations safer.

Replace manual lifting processes with DC chain hoists. Chain hoists can make lifting and moving loads more ergonomic and safer for your operators. Studies show effective ergonomic interventions can lower the physical demands of manual material handling. Control pendant cables are easy to adjust to match the needs of each operator, requiring no wiring when adjusting the length. Operators can use the ergonomic push buttons with gentle actuation force.

Easy Installation and Maintenance

DC chain hoists are easy to install and maintain. Installation is easy with the suspension eye to stationery mounts or trolleys. Plug and play electrical connections make set up and replacement of key components like pendants and connection to electric trolleys quick so you can get to work and stay working.

With minimal maintenance required, DC chain hoists are easy to maintain and service over the life of the equipment. Easily view the elapsed operating time counter to see when some maintenance items are needed. Operating parameters can also be read from the integrated diagnostic interface to make diagnosing error codes quicker. In addition, the gearbox and slipping clutch are maintenance free for us to 10 years, the brake for 5 or more years, depending on your usage. The design of the speed-monitoring braking and clutch makes an extremely safe, reliable, long service life.

Choosing the DC Chain Hoist Solution for You

Adding new or replacing existing lifting equipment in your facility can make your operations safer and more efficient. DC chain hoists make lifting and moving loads ergonomic, even eliminating manual lifting in your processes. Demag DC Electric Chain Hoists are stocked in capacities up to 11,000 pounds and offer an extremely cost-effective lifting solution within this capacity range, when compared to other lifting options like wire rope hoists. Consult our buyer’s guide to find the DC chain hoist that will fit your needs. Then reach out to our experts to talk further about your application or reach out to one of our authorized dealers in the USA or Canada to configure your chain hoist in our Chain Hoist Designer tool.

The Demag DC Chain Hoist Buyer’s Guide

Step 1: Start With Capacity

The product line of DC chain hoists consists of 7 different capacity model chain hoists that are packed with features and perfectly sized to meet your needs. We stock DC chain hoists in the following capacity ratings: 275 pounds, 550 pounds, 1,100 pounds, 2,200 pounds, 4,400 pounds, 7,000 pounds and 11,000 pounds. DC chain hoists can easily meet any capacity rating needed. The capacity of any model can be reduced to meet your unique requirements. Each capacity range helps solve unique challenges so the first step in the buying process is determining which capacity model will perfectly suit your application.

Step 2: Determine Available Power Supply Options

Demag electric chain hoists offer a wide supply voltage range, covering most 3-phase supply voltages found worldwide. For the USA and Canadian markets, we stock hoists suitable for the most common industrial 3 phase voltage supplies: (208V) 220-240V/3/60Hz, 220-240V/3/60Hz, 440-480V/3/60Hz, and 575V/3/60 Hz. When your project requires variable speed, Demag DCS chain hoists offer the unique ability to run within a wide range of voltages and frequencies. These requirements cover many of the most common voltages found worldwide, 380-480V/3/ 50Hz or 60Hz.

Step 3: Find your Required Lift Height

In the USA and Canada, Demag stocks chain hoists with 16’-5” of available lifting height, covering the majority of the most common industrial requirements. We also stock a longer lifting height of 26 feet in our most popular chain hoist models. When lifting needs exceed 26 feet, Demag offers some of the longest lift heights found in the industry. Applications with the hoist on a building or in the wind power generation industry can require lift heights as much as 600 feet. Demag can offer proven solutions to meet these extreme lift heights.

DC chain hoists are on the shelf ready to lift, completely built with the chain and chain container. This means we can supply the most common models quickly. In addition, many distribution partners in the US and Canada stock Demag chain hoists throughout around North America to further reduce delivery time and shipping costs.

Step 4. Determine your Suspension Solution You Need

Demag DC chain hoists are flexible to use with a fixed mount or be suspended from many types and brands of trolleys. The standard suspension bracket from Demag makes installation quick and easy. The bracket acts as both a lug and a hook making installation safe and secure. Demag trolleys are available for I-beams or wide flange beams for flange widths up to 19.68 inches. Universal trolley wheels ensure smooth travel and low rolling resistance on push/ pull manual trolleys.

When motorized trolleys are needed, you can quickly and easily add a motor to your manual trolley for steady travel with smooth acceleration and deceleration. When needed, travel speeds can easily be adjusted to meet the exact needs of your application. Motorized trolleys have integrated control systems that are plug and play, just plug in the cables supplied and you are ready to work.

When you need to suspend a DC chain hoist from an Enclosed Track system, our chain hoists are flexible to meet your needs. If you have our industry leading KBK Enclosed Track System, we have a wide range of options to meet your needs for suspending a chain hoist. Even if you are using another brand of enclosed track system, our chain hoists make suspending the unit from nearly any system easy.

Step 5. Choose The You Control Need

The Demag DC chain hoist comes standard with an ergonomic DSC pendant to control the up and down lifting motions. When you need to control movements of the trolley and bridge, Demag offers the ergonomic DSE-10 pendant. Simply unplug the DSC pendant and plug in the DSE-10. Our quick plug and lift controls require no time-consuming wiring. DC hoists can also be equipped with a variety of other pendants and radio controls from Demag or from other manufacturers, so the possibilities are almost endless.

Demag offers unique pendant options that can help improve productivity in many industrial applications. Our ergonomic Manulift handle puts the control into the operator’s hand. This handle integrates the pendant and hook with rocker switches controlled with the operator’s thumb. The handle can be used with the right or left hand and allows operators to quickly lift, move and position the load with one hand. It is ideal for lifting and setting smaller loads within comfortable reach of the operator. Demag in the USA and Canada locally stocks Manulift units up to 550 pounds with capacity up to 1,100 pounds available for order from the factory.

Similar to the Manulift handle, the DCBS electric balancer is available for loads up to 550 pounds. The DCBS handle and sensors pick up the slightest movements of the operator’s hand and translates them to up/down movement. Floating loads is easy with the DCBS either using the grip or two hands on the load. Not sure if you need a chain hoist or balancer? Read our article- Chain Hoist or Balancer? 5 Considerations to Evaluate Your Lifting Needs.

Step 6. Choose Lifting Speed

Demag offers the fastest and widest range of lifting speeds in the industry. Choose from our standard two-speed model hoists giving you additional precision at low speed or the extreme precision offered by our stepless variable speed hoists. We offer the industry’s fastest lifting speeds up to 100 feet per minute. These faster hoists are an excellent option for very fast, high production environments or when very long lifting heights are needed.

Step 7. Determine Your Headroom Needs

The standard Demag DC hoist has a low-profile design offering excellent headroom to allow it to fit in buildings and locations with low ceilings. This profile can be further reduced by using an optional low headroom trolley.

Step 8. Integration with External Controls

Chain hoists are just one part of how you lift. When adding a chain hoist to an existing jib crane or overhead bridge crane with motorized travel or even motorized grippers, your hoist will need to be integrated with existing electric controls. The first step to integration is knowing the control voltage of the existing power system. Then you must determine how the hoist and travel motions will be controlled. It is likely all these motions can be controlled from the same pendant, radio or PLC. Consider where the pendant, radio or PLC will be located. Demag offers several control interface panels that can suit nearly any situation to simplify this process.

Step 9. Additional Options

Demag chain hoists offer the most extensive options available in the industry. Nearly any special condition can be met with our additional features to help improve performance in almost any environment. If your DC chain hoist will be operating in hot or cold temperatures, wet or corrosive environments, there is an option to optimize the operation of the hoist. All chain hoists are standard IP55 outdoor rated and have a durable powder coat for extreme durability in a variety of environments.

Whether you are adding options today or in the future, DC chain hoists are designed to meet your changing and evolving needs. Synchronized lifting of multiple hooks, automated or semi-automation, and much more are available. Demag chain hoists offer the most extensive options available in the industry.

When automated control is needed, there is a DC chain hoist solution to fit your needs. Demag chain hoists can be controlled with a PLC and can be equipped with encoders, geared limit switches, and other components for automation application needs.

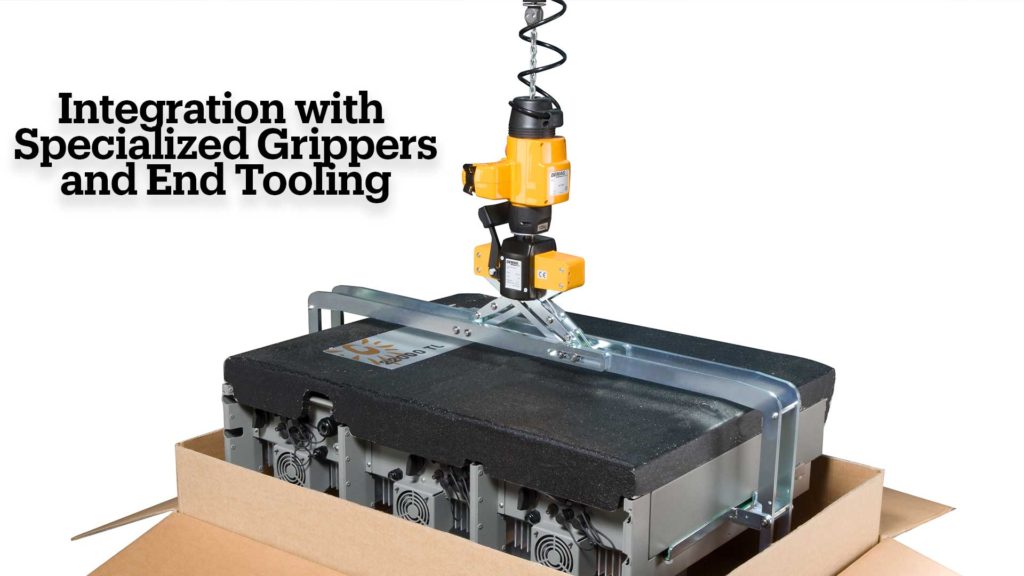

When you need to find a chain hoist solution for your lifting needs, the DC chain hoist product family is designed to meet a wide range of lifting needs. In addition to the features that come standard or special features that can be added, DC chain hoists can be further customized with specialized end tooling and grippers. Customized end tooling can make lifting components safer and more efficient for your operators. Our authorized dealer network in the US and Canada can help you integrate existing custom tooling or design new tooling to optimize your processes. Contact us to talk about your needs and how DC Chain Hoists can meet your needs.