Overhead Crane Lift Height: Key Takeaways

- Lift Height Defined: Lift height is the distance from the floor to the hook’s saddle in its highest position, crucial for ensuring enough room for lifting and repositioning loads.

- C-Dimension: This measures from the hoist trolley wheels’ running surface to the hook saddle, determining maximum lifting height.

- Headroom: The space between the lowest obstruction and the rail top; critical in existing buildings where rail height cannot be changed.

- Optimizing Lift Height: Adjusting girder configurations, such as using side connections and double-girder designs, can optimize lift height in constrained spaces.

- Reeving Impact: Different reeving configurations alter the c-dimension and affect lift height capabilities.

A common question we get in the field regards the specifics of c-dimension. In short, c-dimension is just one of many specifications needed to design an overhead crane project. To really understand this dimension, though, you need to have a full understanding of lift height.

In this post, we will give you the basics you need to know on overhead lift height, headroom, and c-dimension, and how they are all related, so you’ll have the knowledge you need as you embark on your next crane quote.

Like many specs when getting a crane quote, everything is interrelated. Oh, what a tangled web we weave! One seemingly simple specification can turn into a panicked research project to understand it all. As we talk about the interrelatedness of c-dimension, headroom, and lifting height, we will also address some other factors that affect lift height and how a crane manufacturer or authorized dealer can optimize these dimensions to meet your needs.

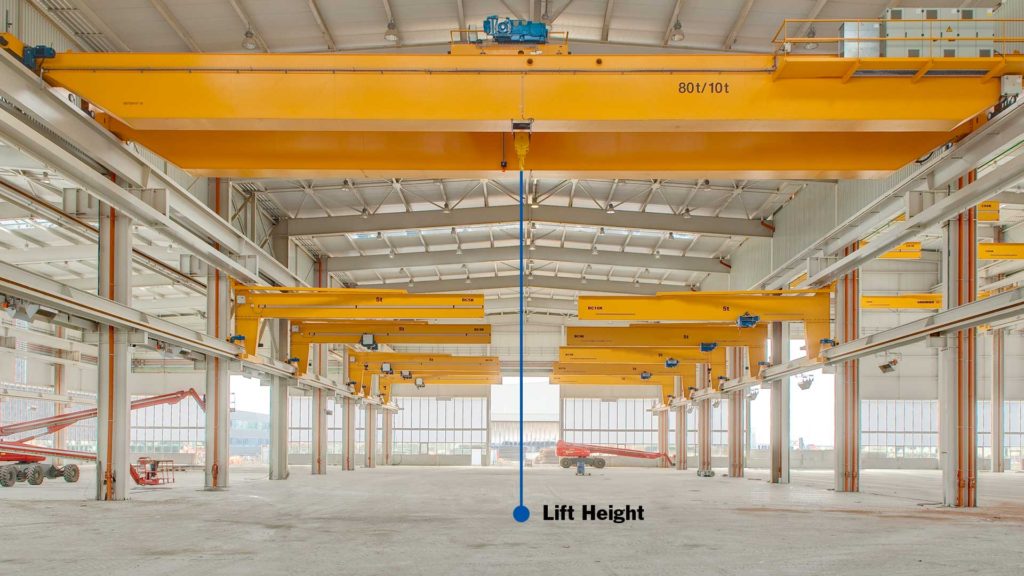

Lift height is measured from the floor to the saddle of the hook on overhead cranes.

What Is Lifting Height and How Do I Measure It?

First, we will tackle the basics. In its simplest definition, lift height is the distance from the floor to the saddle of the hook, when the hook is in its uppermost position. Lift height is a vital measurement in any project because it assures there is enough room to lift or lift and reposition the load you are lifting.

Miscalculating lifting height can be catastrophic to a project, so properly measuring lift height is key. The first step to success is understanding what you are lifting, how it needs to be lifted or moved, and any restrictions you have so the lift height can be optimized for today and in the future.

What Is the C-Dimension and How Is It Related to Lift Height?

C-Dimension is the measurement from the running surface of the hoist trolley wheels to the hook saddle.

The c-dimension tells you the maximum lifting height that the hook can be lifted. It is the point measured from running surface of the hoist trolley wheels and the hook saddle. This dimension gives you information on what hoist you can use since your c-dimension is a fixed measurement on each hoist. Since we are bringing hoists into the picture and determining lift height, it’s now time to talk about headroom.

What Is Headroom and How Is It Related to C-Dimension and Overhead Lift Height?

The headroom available on an overhead cranes is the space between the top of the lowest obstruction and the top of the rail.

The headroom available in a building is the space between the top of the lowest obstruction and the top of the rail. Unfortunately, in most existing buildings, the crane rail height cannot be changed. If a crane is being designed into a new building, you will likely have more control over the rail height set by the architects. Headroom, c-dimension, and rail height all must be considered when determining lift height for your crane.

Is There Any Way to Affect the Lift Height of a Crane Being Installed into an Existing Building?

Girders can connect to end trucks with different types of connections to optimize measurements in the design of your project.

Even though you don’t have total control over every measurement in an existing crane bay, there are options to optimize the dimensions of the crane. First, your girder configuration can make a difference.

How the girder is connected to the end truck can affect the maximum lift height. Connecting a girder to the end truck with a side connection instead of a top connection can optimize the crane dimensions to allow it to fit within the available headroom.

Girders can be designed to connect to end trucks and fit within a space in a multitude of ways and be built to optimize these measurements. They can be built from short to tall and everything in between to optimize lift height. Your ultimate lift height is dependent on the height of the girder, the end truck dimensions, the girder to end truck connection design, and the c-dimension of the hoist.

Depending on your design, a double girder crane can help maximize the lift height of your overhead crane project due to the benefit of the space in between the girders.

Choosing between a single-girder or double-girder crane can help maximize all three measurements, including lifting height. On single-girder cranes, the hoist is always underrunning. Double-girder cranes have the benefit of the space in between the two girders, allowing you to eke out a little bit more lift height depending on how the trolley is designed on the girder.

Third, choosing the right girder and hoist combination can optimize your lift height. Like described above, a double-girder crane can optimize overhead lifting height because the hook can lift higher than the bottom of the girder, with the ability to be contained between the two girders. The main factor here is determining where the trolley or hoist will run on the girders that best fits the lifting you will be performing.

Single girder cranes have hoists that run on the bottom flange of the girder.

On a single-girder crane, the hoist can only run on the bottom flange of the girder. To maximize lift height on a single-girder crane, manufacturers design special low headroom hoists. The components of these hoists are designed to optimize lift height. For instance, the body of a hoist on a low headroom model will travel in parallel to the girder rather than above or below it.

Components like control boxes are moved to minimize the amount of equipment riding over the top of the girder. Low-headroom hoists also tend to help optimize overhead lift height since they are not located directly below the girder so you’re gaining a small amount of height with the different mounting type.

Is Reeving Related to C-Dimension and Lift Height?

Reeving allows a hoist to lift additional weight. C-dimension changes with each different reeving configuration.

The last restriction we will talk about that is involved with c-dimension and lift height is reeving. In its simplest definition, reeving is the path a wire rope follows around the drums of sheaves. Different reeving such as 1/1, 2/1, 4/1, 4/2 and more is done so the hoist can lift additional weight. Each different reeving number has a different c-dimension because the ropes must be at the proper angle at the top of the lift height. As you are working through a project to get to a final print, always remember that when reeving changes, so will your c-dimension.

With so many interconnected specifications in overhead crane projects, doing your research on measuring lifting height and working with an expert is key. As your next crane project draws nearer, make sure you fully understand what you need to lift, how you need to lift and/or move the load, and where you will be doing the lifting. Working with your experienced crane dealer or crane manufacturer will assure your next project meets your needs.

If you’re getting ready to request a quote for a crane, we’ve put together 8 key details you need to know as you get ready to work with a crane dealer or manufacturer.

Learn More About Overhead Lifting Height Today

Have additional questions about lifting height, how to determine lift height, or more? Demag is here to help you, so feel free to contact us today with any of your questions.