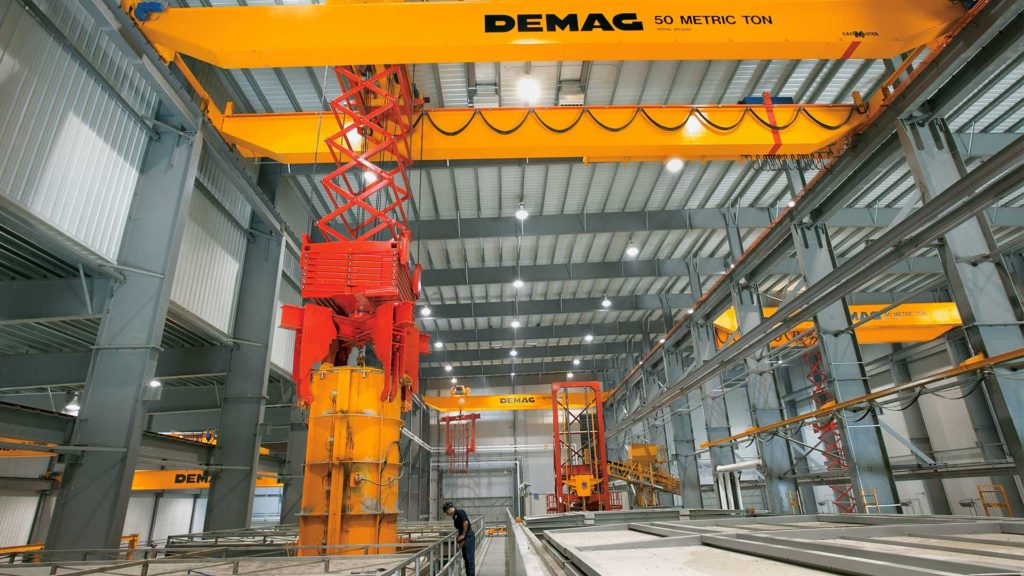

Lifting equipment used in precast plants needs to be severe duty. These businesses rely on precast cranes to keep production flowing so a reliable solution is absolutely necessary. Whether moving massive finished products or transporting concrete buckets, the equipment needs to be built to withstand the dusty, wet environment and heavy loads.

Demag Has Expertise in the Precast Industry

Precast plants handle a variety of concrete products like long and heavy hollow core products, lifting walls and slabs in confined spaces, large beams in storage areas, and loading final products into trucks. The materials used to make the final product generate a lot of dust and use water to create the concrete mix, resulting in an extreme environment.

Because of this extreme environment, the components must be built to withstand these elements. Lifting equipment used in precast plants are a vital part for throughput and efficiency so working with a manufacturer and dealer who works with precast cranes and has experience in the precast industry is a must.

Choose Precast Industry Cranes and Hoists that Receive a High Duty Rating

The duty rating of precast cranes or hoists used in any application is important. In the USA and Canada, the Crane Manufacturer’s Association of America (CMAA) and Hoist Manufacturers Institute (HMI) publishes specifications for the manufacturing of cranes and hoists which include the duty ratings A – F.

Duty rating allows for a specified service class from infrequent service to severe service. It is calculated based on many details like capacity, number of lifts in a given timeframe and the conditions in which it operates. It is critical to work with a crane dealer or crane manufacturer in your area that follows your regional standards.

Concrete products can be very heavy! The capacity of the precast concrete cranes and hoists is always a critical specification. This assures the loads can safely be lifted. Capacity is just one element of safe lifting. The below-the-hook attachments are vital as well. Depending on what shape the product is that you are lifting, there are different below-the-hook attachments that can help you safely and efficiently lift components.

Precast Concrete Cranes and Hoists That Are Designed to Perform

Because of the dust and water in the precast environment, it’s important to incorporate components that can withstand these elements. The equipment needs to be built to withstand the high volume of dust in the air and moisture from creating the concrete mix. Electrical components like precast industry cranes and hoist travel motors need to be protected to keep both the dust and moisture out, or be designed in a way to minimize the amount of traditionally electrical components are contained in them.

Hoists like the Demag DH wire rope hoist are tailored to fit into these extreme environments. The DH has limited electronics using a conical rotor brake motor paired with a mechanical microspeed motor. This minimizes the electrical components needed for travel and braking and allows the hoist to precisely position the load. The conical rotor motor and mechanical microspeed motor also allows for a wide range of speeds to optimize the production process.

Demag Has the Precast Concrete Hoists and Crane Components for Your Facility

When you need to lift loads in an extreme environment like a precast yard or plant, make sure you partner with an experienced crane manufacturer or dealer. Regional organizations like the Material Handling Institute (MHI) and its groups standardize crane and hoist manufacturing specifications to meet the needs of extreme environments.

Learn more about Demag’s precast hoists that can be used in extreme environments!