Building ships is big business, literally. Overhead cranes and hoists do the heavy lifting during construction. Ship builders need to lift heavy, large, and sometimes awkward pieces, which is where ship-building cranes come in. Even when ship repair companies need to service a ship, components can be very heavy. Demag has built cranes for ships and the unique construction and repair work they require. As Demag grows, and the demand for ship-building cranes increases, we will continue to partner with companies all over the world to meet these essential needs.

Looking at the History of Ship-Building Cranes

With 200 years of history, Demag has built many different types of ship-building cranes, from the overhead travelling cranes we are known for today to the past when we built harbor cranes. Demag has built cranes for ships and their construction and reparation, both in the past and present. In 1908, we received an order from the Harland & Wolffe shipyard in Northern Ireland for a 40-meter tall, 150-ton floating crane to build ships like the famous White Star line which included the ill-fated Titanic. Today, Demag overhead cranes and hoists are used to build ships all over the world.

Modern ship-building techniques require cranes and hoists to lift and position prefabricated sections to be welded onto the body of the ship. These prefabricated sections are normally built somewhere on-site and transported to the building dock. This means lifting equipment needs to be able to lift large, potentially awkward loads efficiently and safely during the production of the ship. Ship-building cranes are designed to move these large, heavy pieces of material safely and efficiently.

Different Types of Ship-Building Cranes from Demag

Due to the modern techniques used in ship building, there are specific needs you’ll find with lifting equipment in these facilities. First, capacities lifted by ship-building cranes and hoists can be very heavy. When the prefabricated components are lifted, they can be very large and bulky. In addition to capacity, these components may be very awkward to lift. Awkward loads need to be lifted in different ways than other types of loads. The potential to use tandem hoists, or multiple hoists, to lift the component may be a solution. Adding different types of below the hook attachments to the lift block can make lifting safer.

Since these ship-building cranes and hoists are used in a production setting, the lifting equipment may be making many lifts hourly or throughout a shift. The duty factor of the crane and hoist is an important consideration when lifting equipment will be making many lifts within a specific period of time.

In addition to the overhead lifting equipment lifting the prefabricated sections, there may be production areas building these prefabricated sections. Depending on the requirements in these areas, it’s important to choose the right lifting equipment for these areas. Lifting in these areas could look very different, using a more standard wire rope hoist to lift or using a chain hoist in combination with an enclosed rail crane system like Demag KBK crane systems.

Ship repair service facilities will also need overhead cranes and hoists to make repairs to ships. Nothing is small on an ocean cruising ship. Cranes and hoists are used to lift motors and broken components from the boat, and to place the new components.

Lifting large, bulky, potentially awkward components to manufacture a final product like a ship, or complete repairs on a large ship, require you to partner with an experienced crane manufacturer and dealer so you can get the lifting equipment that will meet your requirements. Learn more about Demag products, like our cranes for ships, that we have successfully implemented in the ship-building industry.

DH Wire Rope Hoist – Hoist Options for Your Special Requirements

The Demag DH wire rope hoist is designed for production applications like ship building and other bulky, high-capacity industries. When a ship is being built in a building dock, the overhead cranes and hoists may need to lift components a very long distance. The hoist may also be making these lifts frequently over the course of an hour or during a shift. There may be a need to safely hold a heavy component at a certain height to complete the manufacturing process. The DH hoist handles load capacities up to 100 tons with a 340-foot lift. When you need to hold a load or need an emergency second brake, add a load hold brake to meet your needs.

The DH wire rope hoist is flexible and precise to meet the needs of even the most extreme environments. The DH can be configured with conical rotor lift and creep motor. This combination is the tried and true Demag FG Microspeed, giving you precise lifting and positioning with a motor that can stand up to the environment. This combination gives you infinite variable speed without the use of electronic components like inverters. The motor combination design gives you a wide range of efficient travel and lift speeds.

Travelling and stationery DH hoists can be coupled to work together in your lifting processes. Coupled hoists can have exact, simultaneous operation in applications where there are large differences between ropes. There is a DH configuration to meet your needs including low headroom monorail, standard headroom monorail, single girder, and double girder travelling with a trolley.

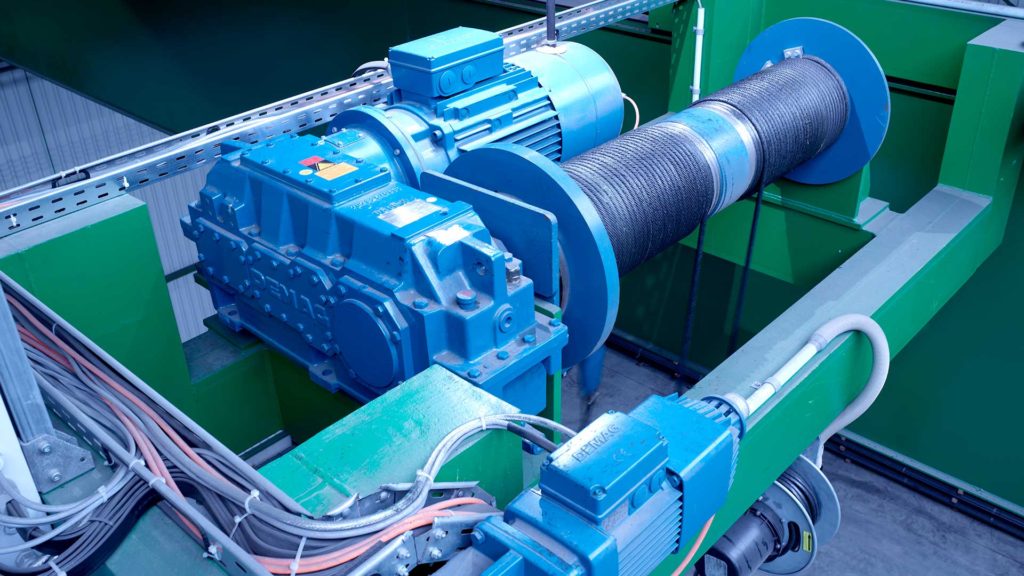

MPW Open Winch

Open winch applications are the most customizable to extreme lifting needs. The Demag MPW Open Winch can lift up to 250 tons and can be customized to meet your specific needs. Our high-capacity winch units are a compact design with low deadweight. When you need high lift speeds and precise positioning of your heavy loads, the MPW is tailored to your needs. If you are in a colder climate, the MPW is designed to operate in temperatures down to -20°F and can include weather protections needed.

Contact Demag for Reliable Cranes for Ships

Building ships is a big business and these companies need to have the right equipment to do the job safely, efficiently, and reliably. With modern ship building practices, it’s critical to work with a crane manufacturer and dealer partner who understands your lifting requirements. Talk to an expert!

Reach out to us to discuss your upcoming new crane project or crane modernization.