Continuous improvement is a cornerstone for Demag product development. Every iteration or version of a hoist that is introduced improves upon itself in many ways like serviceability. When you look at Demag wire rope hoists, improved serviceability was seen from the generation 1 DMR hoist and now to the generation 2 DMR wire rope hoist.

In this post, we are going to focus in on the Generation 2 Demag DMR wire rope hoist. There were improvements to the serviceability of the DMR between the Gen 1 and Gen 2 equipment for complicated repairs, setting a new precedent for ease of access. This writing is in June 2022 and the Gen 2 DMR hoist is currently being sold into the United States and Canadian markets. Read more about the improved serviceability on these hoists.

Modular Platform for Easy Retrofit and Integration

The Demag DMR wire rope hoist was designed on a modular platform that allows for the hoist configurations to have the same contactor, inverter, and processor controls. In most cases, the hoist and trolley integrate into the same space with less deadweight, making it ideal for crane modernizations and hoist replacement projects. Versatility was designed into the control allowing the Gen 2 DMR hoist for easy retrofit and integration into the control circuitry present on pre-existing cranes, including 2004 and newer CANBUS variants.

Improved Lift Motor Drive Connection to the Hoist Gearbox

The days of pressed and glued pinons, which were virtually unremovable and restrictive, are over. The lifting motor drives the hoist gearbox through a starwheel coupling connection on both motor types in Gen 2 DMR rope hoists. This design eliminates a direct oil seal on the motor shaft and the potential for oil seeping into the stator. Removing the motor no longer requires draining and access to the front end of the motor, including the bearing, is maintained so it’s easy to rebuild or rewind the motor.

Easy to Reference Oil Quantity Measurements

Since the DMR hoist is designed to be a modular platform, each configuration can be positioned as needed for your project. In the past, this meant referring to complicated tables to determine the oil quantity for the configuration you were working on. The overall Gen 2 DMR hoist design is square making each configuration requiring the same amount of oil.

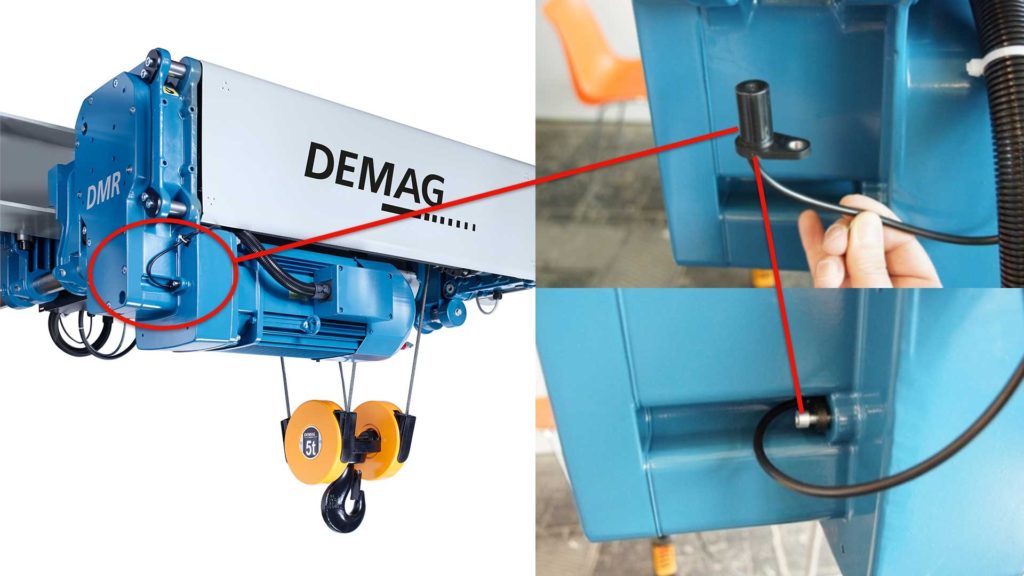

External Access to the Pulse Wheel and Reader

When compared to the DR Pro series hoists, the DMR rope hoist has external access to the pulse wheel reader. In the DR Pro, technicians need to completely remove the brake assembly and endcap of the motor to gain access to the internally mounted pulse wheel and reader. On 2-speed DMR hoists with processor control, the access to the pulse reader is found on the outside of the gearbox. The new style pulse wheel is robust and can be easily accessed in the coupling chamber by simply removing the motor at its front flange.

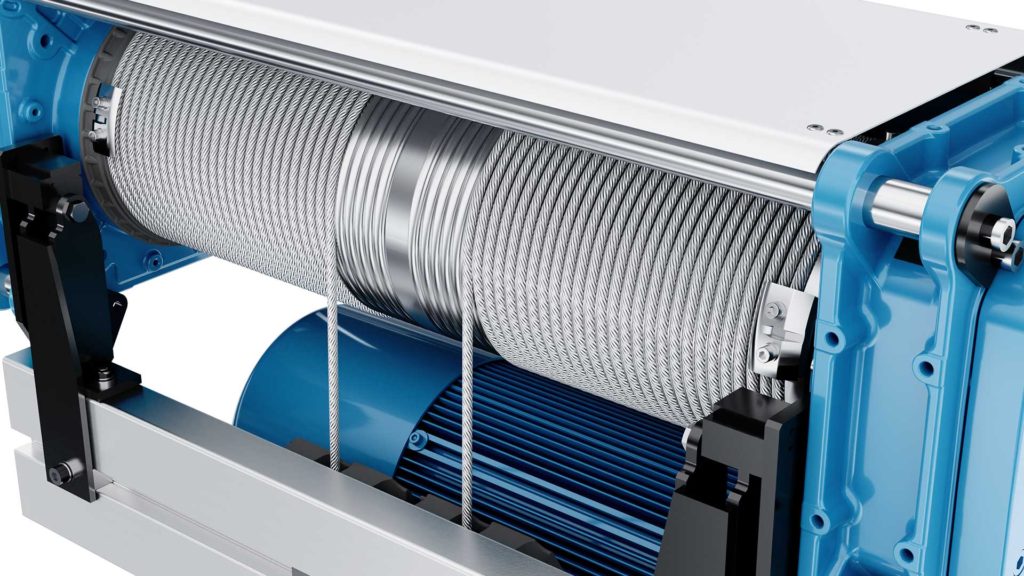

New Drum Design Delivering Longer Rope Life

The drum design of Gen 2 DMR rope hoists were designed with a larger diameter improving the D/d ratio, which can deliver longer rope life due to improved bendability and flexibility. The wire rope is attached with clamps, a more traditional and less proprietary method than previous hoists. In addition, the bottom block lead-in guides were redesigned to be two pieces, allowing the pieces to fit around the wire rope, eliminating the need for unreeving the bottom block when changing them.

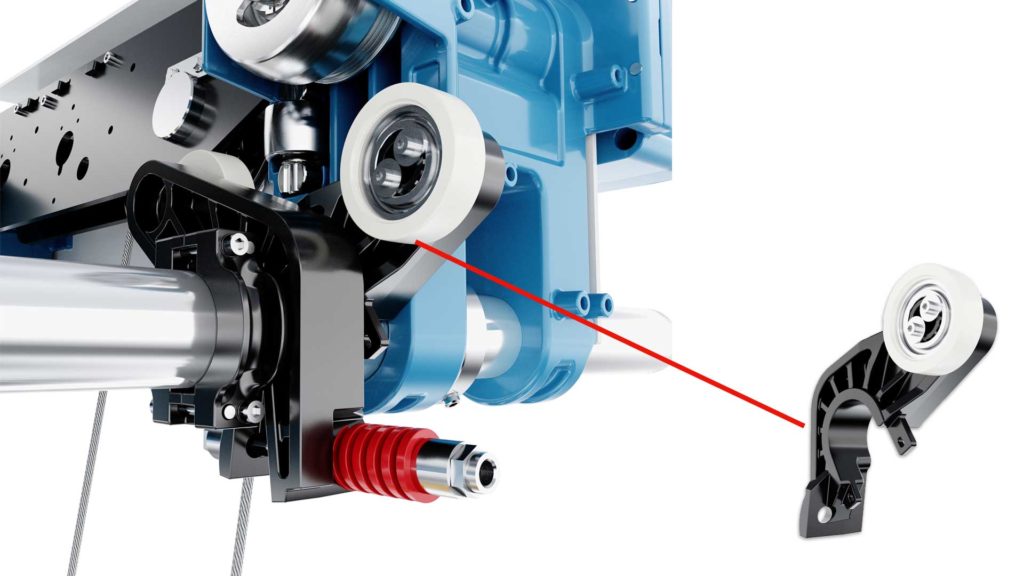

New C-Shaped Thrust Rocker Design

The thrust rocker on Gen 2 Demag DMR hoists, which provides pressure for the trolley wheels, was redesigned and improved. DR Pro hoists are designed with a complete wrap around, o-shaped, thrust rocker requiring technicians to split the trolley. Splitting the trolley requires the service technician to support it from below or remove the hoist from the crane. Next the technician must jack apart the trolley after removing the set screws.

On Gen 2 DMR hoists, technicians no longer need to split the trolley apart to install replacement parts. The new design is a wraparound c-shape with a pivot point that wraps around the load bar at the bottom of the trolley. The clamp that secures the lateral position of the thrust rocker assembly is bolted together and robust. This no longer requires creating a stack of snap-on plastic wrap-around interlocking spacers.

Trolley Features for Efficient Installation

Additional features were designed to the trolley to cut down on the setup time after assembly. The trolley has prepared bore holes for mounting the trailing arm for attaching the festooning and predetermined locations for limit switch mounts. With the crosshead held in position with nut and bolt fasteners, it’s easy to install and remove when needed.

No External Plugs on the Electrical Panels

Electricians will notice the external plugs have been eliminated on panels on Gen 2 DMR hoists. In most cases, cables are brought through grommets and terminate on plugs or terminal strips inside the panels. The same is found on Demag DMR hoists with SafeControl.

The intent is to reduce complicated troubleshooting of intermittent problems from eternal connectors loosening and deteriorating over time. External plugs can reduce installation and setup time, but suffer from loosening pins, wires, and terminals with use.

Generation 2 DMR wire rope hoists were designed with features to make serviceability of complicated repairs easy for crane service technicians. Continuous improvement is important for every manufacturer. If you’re a crane service technician, make sure you’re prepared for your next Demag DMR wire rope hoist service call and familiarize yourself with the new features of the Gen 2 product.

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023

- Maintenance and Service Tips for Demag KB and ZB Motors in Non-Crane Applications - February 7, 2023