Demag provides documentation with the delivery of the equipment you order. There is also additional documentation that may be helpful to the owner of the equipment and to crane service technicians who come in to perform maintenance and repairs. Making sure key people who maintain your Demag equipment have these manuals for reference is critical.

Because Demag sells through an expert network of dealers in the United State and Canada, our dealers are a great resource for assistance with documentation. This guide will go through the types of Manuals and Documentation for reference for Crane Service Technicians or Crane Inspectors, as well as what to keep on-file, if you own Demag equipment.

After Sales Manuals

After sales manuals, or ASM, are the support information delivered with your product. When it comes to cranes, they come with a bundle of support information including a summary of the components, layout drawing, electrical circuit diagram, and compilation of published manuals. ASM materials were provided in 3-ring binders in the 1990’s. Today they are delivered electronically through a link for download.

Installation, operation, set up, start up, and parts information are key parts of the information contained in the overall collection of documents. Manufacturer’s inspection and maintenance requirements are also contained here. The ASM should be kept in a safe place for the life of the equipment by the end user/owner and the Demag dealer that made the sale.

ASME standards establish the requirement for an After Sales Manual. OSHA, ASME and CMAA give validity to the manufacturer’s information. These organizations state that a maintenance program must exist. The ASM is a key source of information for the end user/ owner of the equipment, especially if maintenance is performed by in-house staff. Demag Dealers can also reference the ASM to determine replacement spare parts, conduct proper maintenance, and create thorough content for an operator training program for specific equipment.

Demag Dealers should be sought out when proper service is required beyond the scope of any in-house technicians. The dealer you made the purchase from should be able to furnish the ASM for your equipment, along with other individual Demag published manuals. In many cases, our Dealers have a copy of the original ASM on file. Older manuals predating digital recordkeeping can also be replaced, but likely will have a fee attached for that service.

Demag Operating Instructions and Other Publications

Operating Instructions, Installation Instructions, Assembly Instructions, Spare Parts, and Technical Manuals are all available through our network of Dealers. Since we sell dealer direct in the United States and Canada, Demag authorized dealers have access to our systems to find them. Our Documentation System libraries individual published manuals for immediate download, searching by document number, product, or document type.

Answers for the many technical questions we receive can be found in one of our manuals. Operating Instructions address a wide variety of technical questions. This document goes further than just covering proper operation of the equipment. Settings, torques, adjustment procedures, inspection targets, maintenance intervals, and oil/ lubrication information can be found in this manual. It’s key information for technicians and inspectors in the startup, repair, and hoist inspection processes.

Wire rope hoists models each have their own published Operating Instructions manual. This should be combined with the Crane Operating Instructions for a complete set of instructions for the Crane Operator. The specific chapters dealing with proper operation should be a basis for an Operation Training session.

Key Documents for Crane Service Technicians and Inspectors

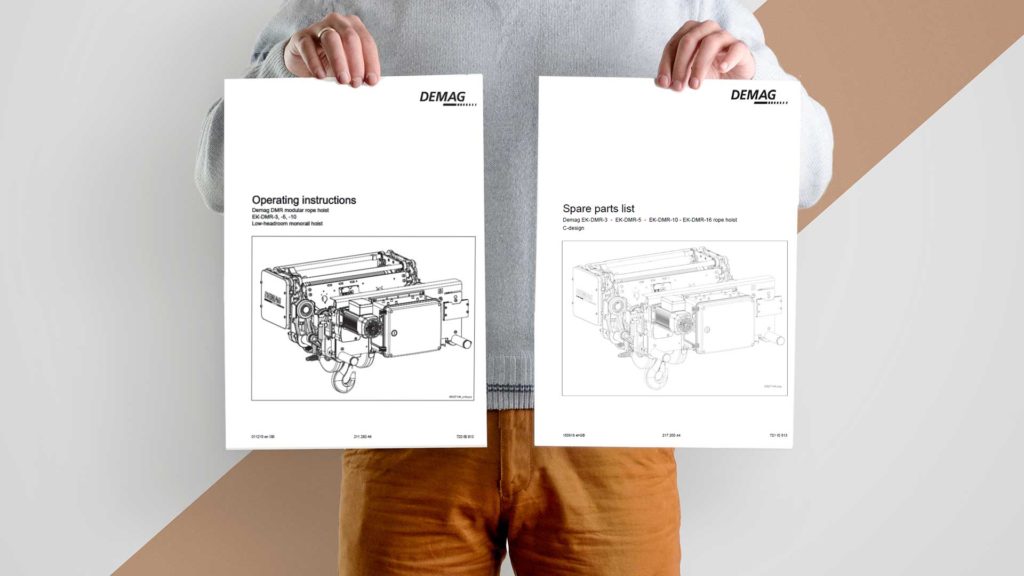

Crane service technicians and crane inspectors should be referencing specific documents for Demag products. The Operating Instructions contain essential information for Crane Technicians. It helps them determine if equipment is properly or improperly functioning and to understand the manufacturer’s setup and adjustments. Technicians have an additional need to know how to assemble and disassemble the equipment for repairs which includes the proper torque values for fasteners. Access to the documentation is essential for service providers to meet the modern liability responsibilities.

Spare Parts/Component Parts manuals are the essential reference for understanding the assembly, disassembly, and reassembly of equipment. Parts and sets are identified by their number for ordering replacements, but the artwork depicts in detail how things fit together. Using the Operating Instructions and the Spare Parts manual together answers the what, where, and how related to technical questions.

As a rule, Operating Instructions and Spare Parts Manuals are two separate publications. Manuals for the Demag DC chain hoist are a notable exception. The Operating Instructions and Spare Parts manual are combined into a single publication. For all other Demag products, you should reference the Operating Instructions and Spare Parts Manual separately.

Crane Inspectors are required to be trained as Crane Operators in modern ASME standards. They need to be familiar with all aspects of the equipment. Additionally, Crane Inspectors need to understand the manufacturer-specific features and special inspection targets. Operating Instructions, Spare Parts Manuals, and Technical Manuals are all useful for their job.

Technical Manuals

Technical Manuals are developed for sales, application engineers, and anyone integrating Demag components into their own designs. These manuals serve as catalogues for selecting a hoist and show key mechanical and electrical engineering information affecting an application. Dimensional information may be useful to identify a specific model of hoist, if the original data plate is found missing. Weights are shown that can help with rigging considerations during the installation process. Additionally, Technical Manuals provide artwork to verify correct assembly and orientation of crossheads, reeving, and other features beneficial for installers and inspectors.

Installation and Assembly Manuals

Installing a crane poses special challenges not faced after the initial assembly and startup. The Installation/Assembly Manual covers the festooning, electrification, and the initial structural assembly, which is critical information at the initial build of the crane on the runway. The Installation Manual and layout drawing provided in the ASM are the two most useful documents for the installer. Since documentation is delivered electronically, it’s assured the information is available at the time of equipment delivery so installation can commence without delay. When the time comes to connect the electrical supply, the electrical interconnection drawing found in the ASM can also prove helpful.

Using Documentation has Benefits for Crane Service

Knowing where to find the information you need will save time while performing services on Demag products. Answers to many technical questions can be found in the documentation. Be aware of the resources available and the value each one contributes. Referencing the proper documentation can help maintain an image of professionalism while leaving no doubt about compliance with the manufacturer’s requirements.

Not located in the US or Canada? User our Global Contact locator to find your local Demag contact!

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- From Customer to Demag USA Technical Trainer - May 9, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023