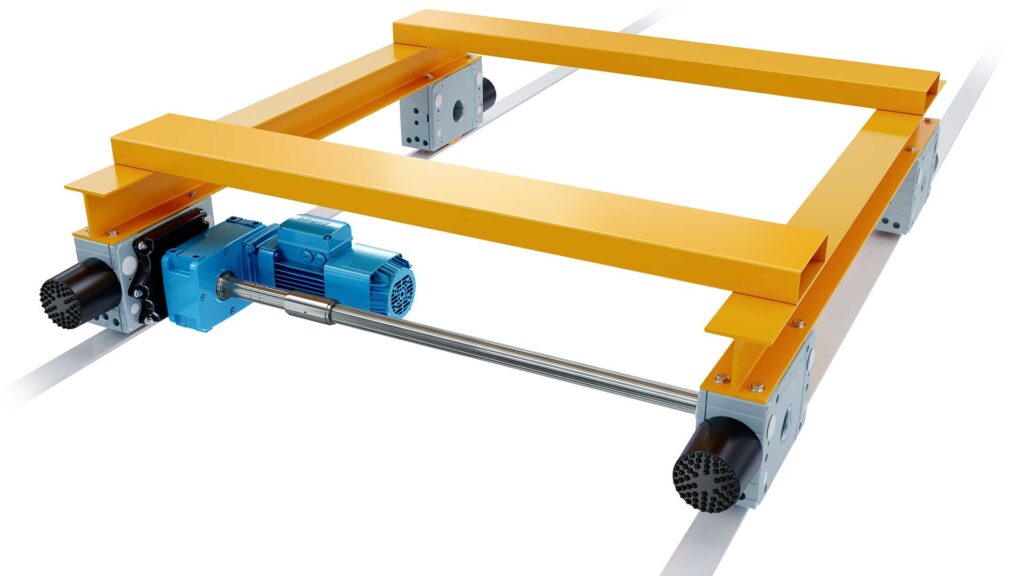

Transfer cars are a critical part of many industrial furnace applications. They are used to move materials between different stages of the manufacturing process, and they must be able to do so accurately and reliably. As a design engineer tasked with developing a transfer car for industrial furnace applications, it is crucial to consider a range of factors to ensure the solution meets the unique requirements and specifications necessary for accuracy and positioning.

Transfer cars play an essential role in facilitating the movement of materials within industrial furnaces, found in steel mills, foundries, and heat treatment facilities. These transfer cars for industrial furnaces are designed to transport heavy loads, withstand high temperatures, and operate reliably in harsh environments. Accuracy and positioning are key aspects when designing a transfer car that travels along a guideway system. Along with budget, engineering a furnace car within your requirements will make the flow of materials through your facility efficient to meet your goals.

Capacity Requirements for Industrial Furnace Cars

As you determine your design for a furnace transfer car, there are a number of factors to consider for the structural and driving components used. First, consider the total or highest capacity load the car will be transporting. If loads with different weights will be transported on the car during the course of your processes, factor in the weight and shapes of the loads.

The distribution of weight is a critical factor, especially when you have uneven loads that will be transported. All the components supporting the loads transported need to be rated for the capacity, so these industrial furnace cars and their components will have optimal performance, safety, and service life.

Environmental Requirements

The operating environment of the transfer car in a furnace application presents unique challenges that must be addressed in the design process. Furnace environments can be extremely harsh, with their high temperatures, heavy dust, and corrosive atmospheres. These factors can significantly impact the performance and reliability of industrial furnace cars, and therefore, the design must account for these environmental factors. When the components can operate optimally in your facility’s environment, you’ll get reliable performance, safety, and service life.

Accuracy and Positioning Requirements

Accuracy and positioning are critical factors in the design of transfer cars for industrial furnace applications. The precise movement of materials is essential to ensuring efficient heating and processing of the materials. Moreover, accurate positioning is crucial for maintaining the integrity of the materials being transferred and preventing damage to the furnace or other equipment.

Designing a Travel System for Industrial Furnace Cars

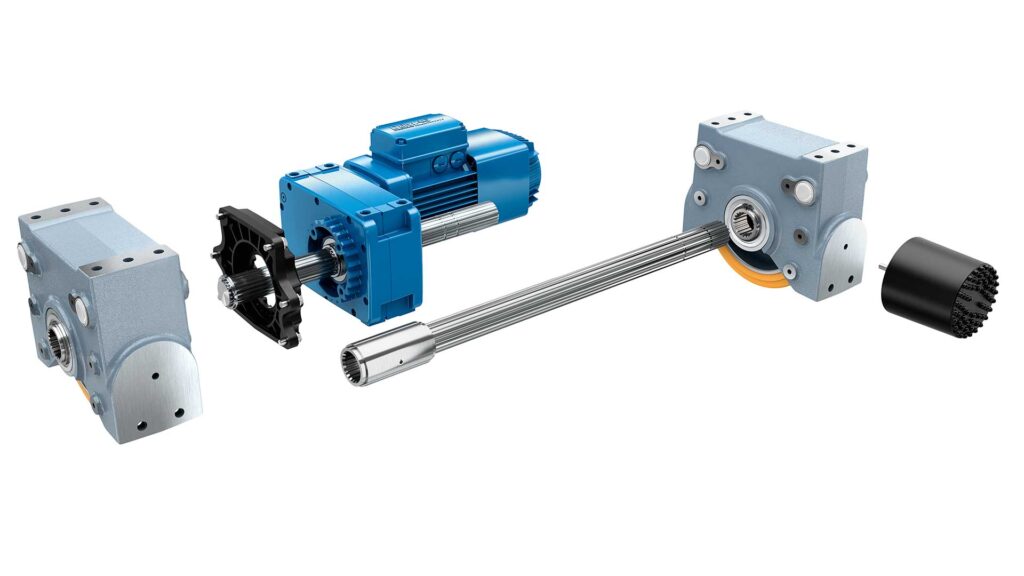

One of the key aspects of designing a transfer car with high accuracy and positioning is selecting the appropriate drive system. The drive system is responsible for moving transfer cars along the guideway system. The guideway system provides a smooth and accurate path for the transfer cars to travel along. The braking system is used to stop these transfer cars for industrial furnaces quickly and safely to your positioning requirements.

The drives system includes the motor and gearbox combination that will create the speed and translate the torque to the wheels. The wheels, which ride along the guideway system, should be rated to the capacity and environmental needs of your facility. Other components include the connectors between the wheels to drive the car as one unit.

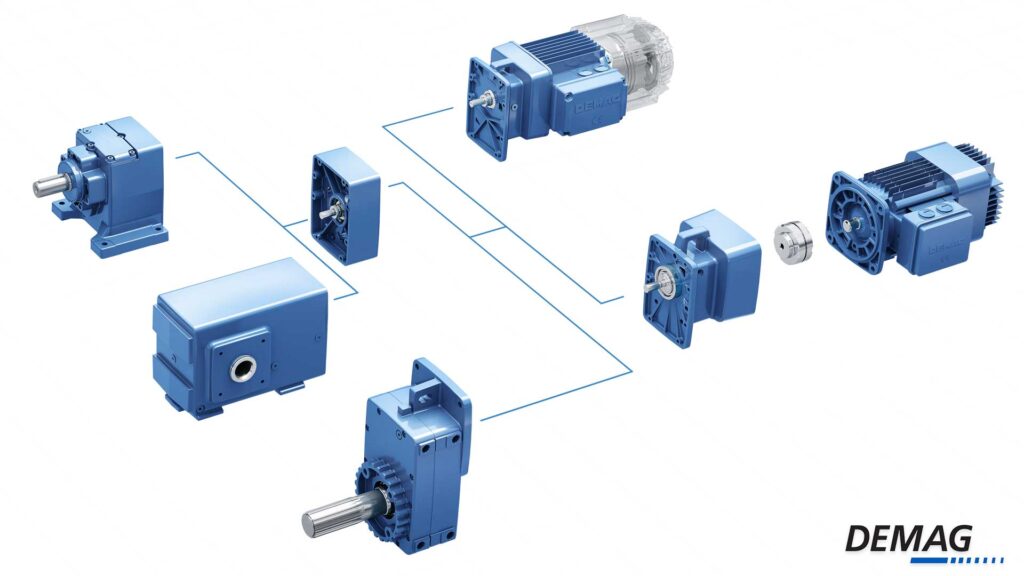

Electric AC Induction Gear Motors

Electric AC induction motors, or gear motors, are commonly used in these applications due to their precision, speed, and ease of integration into motion control components and automation. These motors can have an integrated mechanical brake. In conical rotor motors, the braking is built-in mechanically. This option can fit the needs of a demanding environment since there is no need for electronic braking. A cylindrical rotor motor has an internal, electrical brake and is commonly inverter controlled. This type of motor can be cost-effective and flexible for a variety of applications.

Gearboxes to Translate Motor Speed

Along with the AC induction or gear motor, the gearbox works hand-in-hand to translate the motor speed into torque. Torque is the more important aspect because the output torque of the gearbox is actually what moves the load and determines how reactive and precise the application can be.

Higher quality gearboxes allow the gears to deliver more precise motion and starting and stopping points due to the way the gears work within it. The ideal types for precise start and stop points include Helical-style gearboxes, Bevel-style gearboxes and Hypoidal-style gearboxes.

Uni-Directional Travel Wheels

Uni-directional travel wheels are what will transport these industrial furnace cars to the different points. The wheels themselves can be matched to your requirements including the material that runs on the rail and whether your application requires flanges. Wheels are available from many manufacturers and you can create a wheel and bearing solution that will work for you. Demag provides complete wheel block assemblies, meaning the wheel, bearings, and housing come in one easy-to-install unit.

Motion Control Components in Transfer Cars for Industrial Furnaces

Another crucial factor in designing a transfer car with high accuracy and positioning is the selection of appropriate motion control components. These components include sensors, actuators, and controllers that work together to provide precise control of the transfer car’s movement.

Sensors, such as encoders and limit switches, provide feedback on the position, speed, and acceleration of transfer cars for industrial furnaces. Actuators are responsible for controlling the motion of the transfer car. Controllers, like programmable logic controllers (PLCs) or motion controllers, process the sensor feedback and send commands to the actuators to achieve the desired motion profile of the transfer car.

The selection and integration of these motion control components must be carefully considered to ensure accurate and precise positioning of the transfer car within the furnace.

Holistic Solutions from One Supplier

Choosing a driving solution that is originally engineered to work together can save you a lot of time and energy. When using multiple suppliers, you need to ensure all the components will work together and ensure the engineering spec of each meets your needs. If a breakdown or issue occurs, you have multiple vendors to deal with to get to the root cause of the problem. Using one supplier allows for an efficient root cause analysis so you’re back up and running quickly. Demag travel drive components are designed to work together from inception so you can have confidence in compatibility.

A complete solution for transfer cars in industrial furnace applications also includes safety features to protect operators and prevent accidents. This may include emergency stop buttons, safety interlocks, and collision detection systems to ensure safe operations and prevent damage to equipment or products.

The design of transfer cars for industrial furnace applications requires careful consideration of the overall layout and space constraints of the production facility, including the size and shape of the transfer car itself. By considering these factors for industrial furnace cars, it ensures they can maneuver through narrow spaces or around obstacles while maintaining precise positioning. Don’t forget to integrate communication and control systems to coordinate movements with other equipment or processes in the facility if it is necessary in your facility.

Designing transfer cars for industrial furnace applications requires a holistic approach. You’ll look at your unique requirements, specifications, and environmental operating factors. These factors may dictate the materials and travel drive systems used.

Precise positioning, accuracy, and reliability are paramount in ensuring efficient and safe operations. By carefully selecting appropriate travel components, accounting for the harsh operating environment, and considering space constraints, you can engineer a well-designed transfer car solution to meet the specific needs of industrial furnace applications.

Contact Us to Learn More About Transfer Cars for Industrial Furnaces

We are a leading supplier of industrial drives, which play a vital role in transfer cars for industrial furnaces. If you’re wanting to learn more about these cost-effective solutions, be sure to contact our team today.

Discover the world of Demag and achieve the highest levels of efficiency and performance!