Tests and Inspections for Safe Crane Operations: Key Takeaways

- Visual Inspection: Conduct a thorough visual inspection before turning on the crane, checking for damage, loose objects, oil leaks, and proper wire rope spooling.

- Functional Tests: Test all controls and emergency stop buttons before powering the crane, ensuring all components function correctly.

- Brake Test: Perform a brake test under load conditions by lifting the load slightly off the ground to ensure the brakes hold properly.

- Reporting Deficiencies: Immediately report any deficiencies found during inspections to supervisors for proper repair by qualified personnel.

- Operator Guidelines: Follow specific safety regulations and guidelines for crane operation, including proper handling of control devices and regular battery maintenance for remote controls.

Safety first. When it comes to proper crane use, safety should be at the forefront of your mind. Keeping your employees safe is easy when you follow our simple five-step process every time before you operate your crane, along with the three safety instructions for operation.

Functional Test Inspection of Your Crane

1. Visual checks before turning on power

Before you even flip the switch to start your crane, you need to do a thorough visual inspection of your equipment. Start by looking for any major damage, including checking all the components. Check for any tags or out-of-order signs. If any are present, do not attempt to operate your crane. Next, look underneath it for any parts and then inspect for any loose objects. While you are looking under it, see if there is any oil leakage caused by the crane. Then, inspect the drum to ensure the proper spooling of wire rope and check the reeving of wire rope or load chain for proper pattern.

Continue your visual inspection by examining the visible portion of the sheave grooves for imprinting into the surface. Also, look at visible rope for distortion, kinking, crushing, unstranding, birdcaging, main strand displacement, core portrusioin, corrosion, broken strands, cut strands and broken wires, which can all affect proper operation.

Finally, check the hook and hook latch for any damage, cracks, distortion, stretch, twist and excessive wear. After that, manipulate the hook latch testing for proper function and check that it’s not hanging up. Finish this part of the inspection by checking the hook swivel, if applicable.

If you have a chain hoist on your crane, check the load chain has any of the above issues. Then, look at the control cable for damage and the pendant and pushbuttons for the same and legibility of labels.

2. Function tests before turning on power

Now that you’ve completed a visual inspection of your crane, it’s time to conduct a functional test before operation. Start by making sure the E-STOP is in the power off position and depress each button individually on pendant for all crane motions to be certain E-STOP is properly working and no pushbuttons are sticking. This may also turn up a ripped or torn pushbutton dust cover.

3. Function test of operational controls

You are now ready to turn on your crane to test how it works. Start by setting E-STOP to the power-on position. Continue by activating and testing all audible and visible warning devices. Then, move the hoist down and up at all speeds. Next, move the trolley left and right. When you move the bridge forward and away, note that this procedure checks the brakes and so movements should be smooth and stopping expedient. Conclude this functional test by raising the hoist to check the limit switch and after putting into operation EVERY SHIFT. Be careful not to create a two-block condition by moving the hook slowly as it nears the upper limit. If the limit fails to stop lifting, be ready to press e-stop. The lower limit should also be checked by running the hook to its lowest position.

4. Brake test under load

Now that you’ve tested the operational controls, it’s time to ensure that the brakes are working properly under load conditions. On the first lift with load and after the inspection(s) above, raise load above ground just a few inches. This will test the holding brake on the hoist. This is also the last test.

5. Reporting deficiency found during inspection

If your visual inspection and functional tests uncover a deficiency, you will immediately need to report this to your supervisor. They will make sure that it is properly fixed. Reporting and fixing issues guarantees that no one will be injured or the crane damaged from a deficiency. Only qualified maintenance personnel should make repairs to the equipment.

Prevention of Accidents

Once you have inspected and tested your crane for safety, there are still some safety reminders to keep in mind to prevent accidents. There are specific regulations and codes you must follow. These need to be explained carefully to all employees who are assigned to operating and/or maintaining your crane. Please remember to make these safety regulations and codes available to your crane operator at all times.

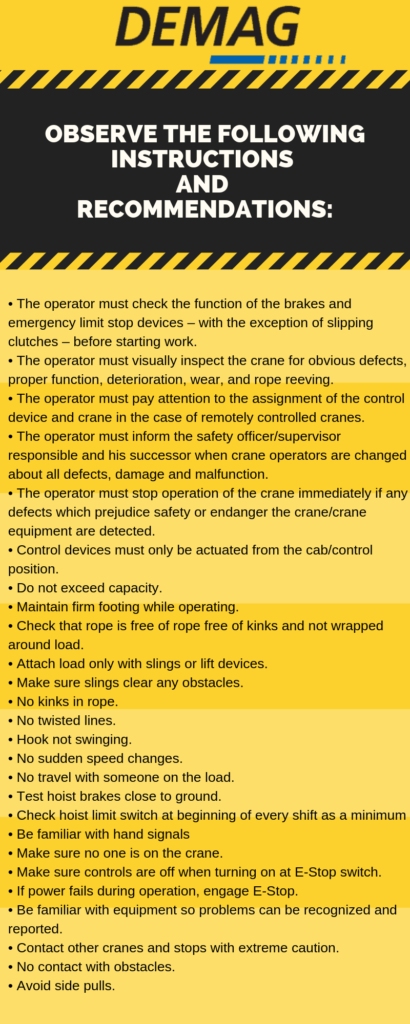

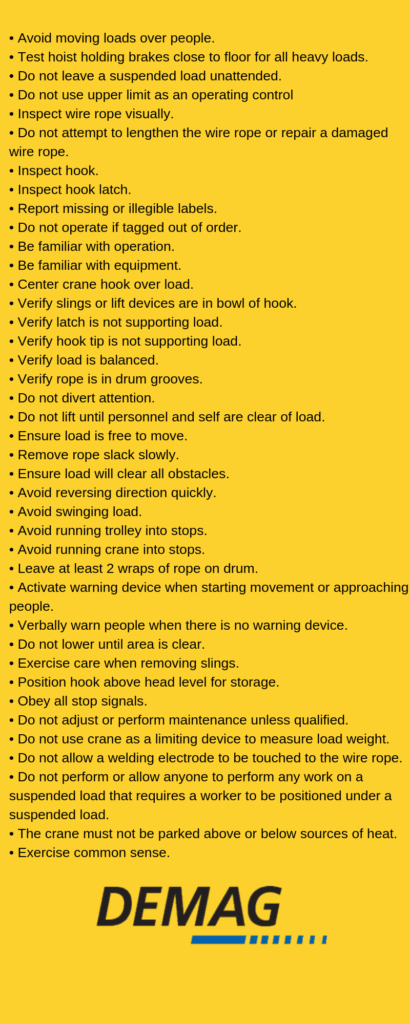

Below is a comprehensive list of all the things that the operator must abide by:

1. What’s Required of the Operator

2. Use of the Control Devices

After the operator switches on the crane by unlatching the Emergency-Stop button or crane switch actuation, he must ensure that all the following are met. All control devices must be in zero position before enabling the energy supply to the drives, plus the control devices must be in zero position and the energy supply disabled before leaving the cab/control position. Finally, the remote control unit needs to secured against unauthorized operation or switching-on before putting the unit down.

3. How to Handle the Control Pendant Cable – Connected Floor Control – Remote Control

The operator then selects the lifting and travel motions –and if necessary the functions of the additional facilities through the control unit. The control unit must always be treated with care. Finally, don’t forget to frequently recharge the rechargeable batteries of remote control units.

These are the

required steps to ensure safety and prevent accidents before starting your

crane. By following these guidelines, you can be certain that your cranes will

perform properly and that your employees remain injury-free.