Transporting raw materials and WIP through your operations requires wheels. The options for industrial wheels are practically endless. As you search for the right option to meet your requirements, you may notice your options start to reduce as capacities and environmental requirements become more extreme. In this post, we will talk about the anatomy of a uni-directional wheel block and the complete Demag travel wheel offering.

Anatomy of a Wheel Block

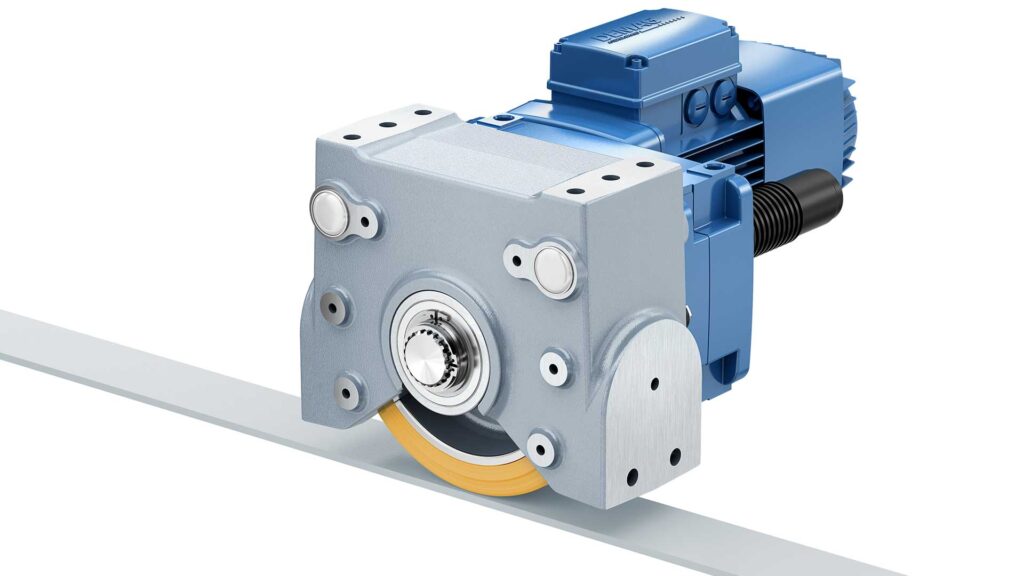

There are many industrial wheel solutions out there to meet different requirements. Demag specializes in uni-directional wheels designed to support heavy capacities in a wide variety of industrial environments. Our product is offered in a wheel block configuration, with only one specialized model of wheel offered as a wheel only. Using a wheel block eliminates the engineering needed when sourcing the different components of the wheel because the wheel block is a complete product ready to attach to the structure for travel.

A wheel block includes the wheel itself, bearings, and structural housing to protect those items. The uni-directional wheel moves forward and backward, not multi-directional like a castor. The wheel can meet the travel needs of your project to include a flange, have another material on it similar to the tires on cars, or be a flat surface to roll across rail or the floor. The bearing is what allows rotation of the wheel on the shaft. Bearings must be matched to the application for capacity and environment to be sure it is rated correctly for the job. The housing is what protects the wheel and bearing and is the structure that will support the structure being transported above.

Demag LRS Wheel Block System

When you require a universal, robust travel wheel, the Demag LRS wheel block can meet your requirements. It’s easy to add to your project without additional design time for loads up to 14,300 pounds per wheel. The LRS wheel block is rated for travel speeds up to 780 feet per minute. It offers a maintenance free, patented travel wheel bearing arrangement and hub splines to DIN 5480. Choose the LRS system when you need good ground clearance for travel on rails across the floor of your facility. Demag has used the LRS wheel system in a wide range of applications like transfer cars, tippers, friction drive wheels, and industrial paint booths.

The LRS wheel has two standard designs, the hydropur tyre and the spheroidal-graphite cast iron wheel with two flanges. The hydropur tyre is flangeless and offers quiet running and high acceleration. The spheroidal-graphite cast iron (GGG70) is gentle on the rail and is designed with vibration dampening characteristics for high or low speeds.

Demag DRS & DRS-M Wheel Block Systems

As your requirements increase in capacity and performance, see what the Demag DRS-M and DRS wheel block systems can deliver. Both model series offer high performance for capacities up to 40 tons per wheel. The DRS is flexible and meets the requirements for a wide range of material handling and travel wheel projects. Both wheel models offer high rigidity with a high quality housing for optimum protection of the travel wheel and bearings.

DRS-M Wheel System

For load capacities from 2.75 – 10 tons, the DRS-M wheel block system has enhanced features to make installation, service, and maintenance easy. The wheel housing comes ready with threaded boreholes for easy integration of guide rollers and rail sweeps. When installing or replacing a DRS-M, the wheel housing has a fixed alignment element ensuring the wheel is positioned precisely, eliminating the need for time consuming adjustment. The wear measurement indicator makes inspecting the wheel quick for periodic inspections and is easily read from afar.

DRS Wheel System

For heavier loads, from 16 to 40 tons per wheel, the DRS wheel block system is the reliable, versatile solution. The housing of the DRS wheel block assures the travel wheel and bearing have the protection needed for optimal performance and safety

Choose the DRS and DRS-M wheel to meet your needs. Wheels with flanges include a double flange, one flange, or no flange, larger diameter without flange for increased ground clearance, hydropur tyres, or flangeless concave polyamide. The DRS and DRS-M wheel system has been used on architectural, transfer car, concrete buckets in factories, and travel components on hydraulic presses.

Demag RS Wheel Block System

When harsh environments or applications, the Demag RS wheel block system can be a solution. It offers performance in a variety of applications in extreme conditions. The RS wheel block housing is made of steel with load bearing on 5 sides, featuring bore holes for connections and buffers, brackets, and guide rollers. Engineered for high-temperature, the RS wheel block can operate in environments up to 480°F/ 250°C with wheel load capacities from 7,700 to 39,600 pounds. Choose from a wide range of standard wheels to meet your travel needs.

Demag DWS Wheel Sets

The most specialized Demag wheel available is the DWS wheel sets. These wheel sets can transport the heaviest loads, rated for capacities up to 132,000 pounds. The DWS wheel is functionally reliable and is easy to install, even when you need to replace a wheel. No specialized tools are needed when installing or removing the DWS wheel. These wheel sets offer a long, reliable life. The DWS wheel set is specialized for operation in extreme environments with aggressive heat, moisture, and dust.

Create a Travel Solution with Demag Drive Technology

All Demag wheel systems can be integrated into a complete drive technology solution. Demag components are modular and designed to work together for efficient, reliable, safe travel of WIP and materials through your manufacturing facility. Create a travel solution to meet your needs with one source, making any engineering, purchasing, and warranty issues easier in the long run.

Powering Industrial Wheels

Add an AC induction or gear motor to your wheel system for smooth, precise travel. The different wheel types have slightly different hardware requirements to create the solution you need. When adding a motor to your travel solution, the motor may be attached to the wheel block system with a torque bracket. This torque bracket accommodates the torque created by the motor and gearbox to create smooth travel along the rail or floor.

Connect two travel wheels together with a drive shaft to create a complete travel solution. Connecting two wheels allows you to add a motor to one or both wheels to meet your requirements. With this solution, you would have a completely engineered travel system to reliable and safely transport goods in your operations.

Industrial travel wheels move WIP and raw materials within a manufacturing or processing facility. Without these material handling devices, facilities would not be as efficient and effective. Wheel blocks create a complete transportation solution with components designed to work together for long life. When you need to create a solution for travel applications, consider sourcing components from one manufacturer. Demag modular drive technology is designed to work together to help you meet your efficiency and safety goals.