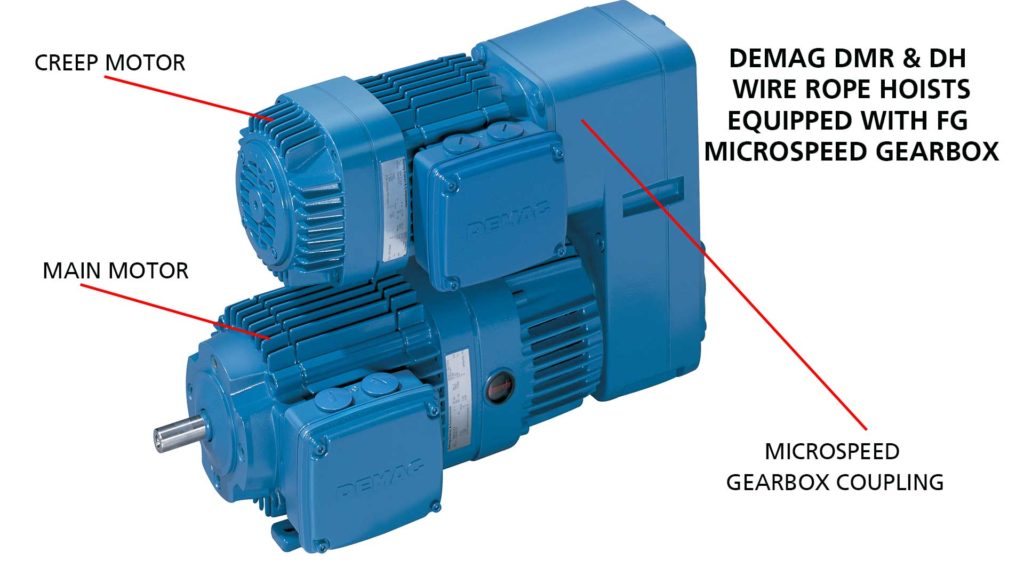

Regular inspection of wear parts on the crane is imperative for safe operation and long life. When you are working on a Demag DH or DMR wire rope hoist equipped with a microspeeed gearbox arrangement, it is important to inspect the micropseed coupling and its roller star. These components should be inspected every time you do a brake adjustment and during periodic inspection of the crane. In this post, we will take your through why inspection of these components is so important and talk about the elements that could cause additional wear.

Demag Conical Rotor Motor Design

KB motors are part of the Demag conical rotor motor series. These motors require coupling connections to the gearboxes due to their conical rotor design. The motor shaft is designed to shift along the centerline direction of the shaft when the motor is energized. The shift is called axial displacement. (If you’re interested in learning more about axial displacement, check out our video on YouTube.) Axial displacement is brake wear and it becomes larger as the brake lining material wears away. When rotation begins in a conical rotor motor design, it is axial displacement that releases the brake so the motor can rotate to run.

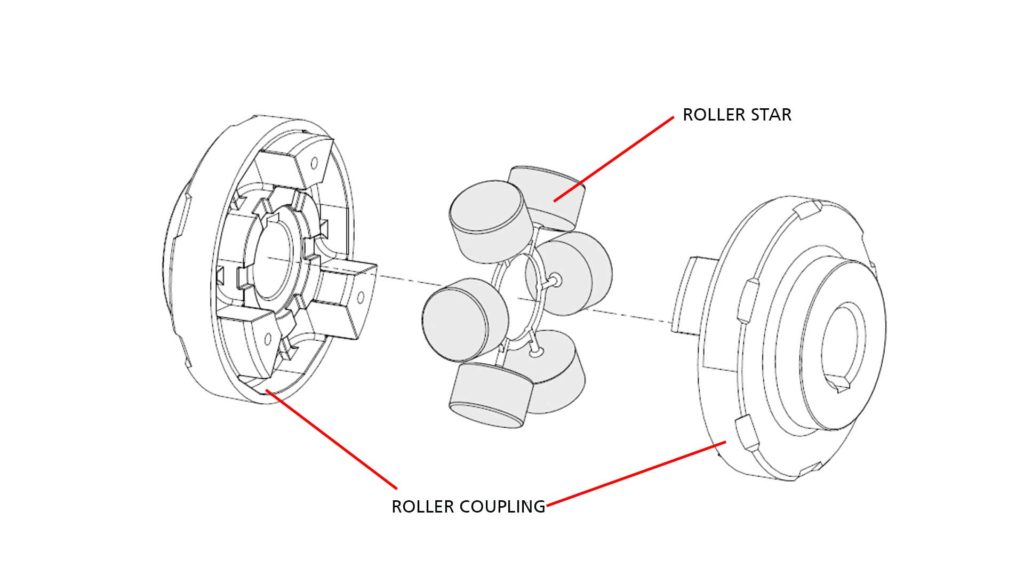

The Roller Coupling & Roller Star

The part that transfers the torque from the motor shaft to the gearbox input shaft is the roller coupling. The coupling half on the motor shaft is designed to move axially and still engage the coupling half on the gearbox. The coupling halves are diecast aluminum and have a steel hub. To achieve this, a roller star made from polyamide is inserted between the two toothed halves of the coupling. The roller star experiences low wear because only rolling friction occurs.

The couplings are primarily used on wire rope hoists equipped with the microspeed arrangement available on Demag DMR and DH wire rope hoists. The microspeed arrangement is designed for minimal wear on drivetrain components over the rated life of the equipment. This also holds true for the coupling between the main motor and hoist gearbox. So any mechanical backlash that does happen in the drivetrain accumulates at the coupling between the microspeed motor and microspeed gearbox.

Mechanical Backlash

When mechanical backlash happens on a Demag DMR or DH wire rope hoist equipped with microspeed motor and gearbox, the microspeed coupling bears the brunt of the impact. Mechanical backlash stops transferring through the system at the coupling because the microspeed motor shaft is positively braked when the motor is not energized. When the motor side coupling half is frozen by the brake in the motor, the microspeed roller star bears the brunt of the impact loading caused by backlash transferring through the mechanism. This makes the coupling a critical element to inspect.

Inspection of the Coupling

The microspeed coupling should be visually inspected at every brake adjustment and during periodic inspection of the crane. The coupling can be accessed relatively easily with minor disassembly. As you prepare to make the visual inspection, make sure to secure or tie up the bottom block before attempting to remove the microspeed motor. The motor should be removed in a straight motion as tilting can cause the coupling teeth to damage the polyamide roller star.

As a crane technician, you will commonly see wear of the microspeed coupling and the roller star in applications with spreader beams and hook attachments that create a constant load for the hoist. In addition, couplings can be affected by cycles, heavy loads and how certain operators control the equipment. Due to the number of variables that can affect the coupling and roller star, it is important to inspect these components during every inspection of lifting equipment.

When you are completing a brake adjustment or periodic inspection on a Demag DMR or DH wire rope hoist, always remember to inspect the microspeed coupling and roller star. Though the microspeed arrangement on the DMR and DH wire rope hoists is designed for minimal wear of drivetrain components, there are specific configurations and situations that can cause wear from mechanical backlash on these components, potentially requiring replacement.

Watch our social media channels for tech tips and videos. Subscribe to our YouTube channel to stay updated with our latest tech tip videos.

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023

- Maintenance and Service Tips for Demag KB and ZB Motors in Non-Crane Applications - February 7, 2023