Material handling applications are crucial instruments to make manufacturing facilities safe and productive. As a custom manufacturer of these applications, you understand how providing an efficient, safe, and cost-effective solution to your customer can help them meet their KPIs. Custom solution providers are always on the hunt for motor and power components to optimize and match the requirements of each application.

As a manufacturing operations director, you’re looking for material handling equipment that enhance your operational performance and productivity. Applications and machinery like industrial tippers, palletizers, rotators, turn tables, and upenders can optimize your operations and make work safer for the workforce. While each application has its own set of requirements, each can be tailored to your unique situation.

Industrial Tippers: Smooth and Controlled Lifting

Essential for combining products together, like chemicals, dry goods, and liquids, during the manufacturing process, the smooth, controlled lifting and tipping motions provided are vital to prevent spillage and ensure safety. A key component to the industrial tipper is the gear motor initiating travel and tipping motions. For unique or non-standard applications, choosing the right components matters.

When specifying an AC induction gear motor for a tipping application, you want to look at the torque, horsepower, and output speed of the application. Torque is important with heavy loads for smooth, efficient starting and stopping. It is also a crucial component of precision, making sure bins stop exactly at the correct location. Horsepower, or the power rating, should be based on the maximum load capacity of the application. This will allow you to efficiently handle all load capacities within the spectrum.

Determine the travel speed for the application. Knowing how quickly the tipper needs to move from point A to point B and beyond will allow the motor to be sized properly. A variable speed motor is often used in this type of application to accommodate the different operational speeds needed during travel. Mechanical motors can be a match to extreme and aggressive environments and specifications. All these specifications together allow for controlled, precise braking and positioning making your tipping applications efficient and safe.

Palletizers: Efficient Automatic Stacking

To automate the stacking of cases, goods, and products onto a pallet, a palletizer can be used. It can reduce the time, cost, and physical strain associated with manual palletizing. Picking, placing, and stacking requires linear and rotary motion. Precision during placement is crucial for safety and cycle time.

In specialized palletizer applications where capacities are high, an AC induction motor with VFD (variable frequency) can be the solution to meet the required speed and torque. The motor will be selected based on the weight of what is placed and the speed at which it needs to move. Torque will assure the linear and rotary motion is smooth and efficient.

Turn Tables and Rotators: Ergonomic and Efficient Rotation

Enhance ergonomics and efficiency in operations where heavy loads must be rotated for assembly and manufacturing. Turntables provide 360-degree access and can be powered for bi-directional movement. Applications can require continuous or intermittent motion and may require variable speed tailored to different tasks. An important detail to know is whether the load will be distributed equally across or on one side of the table. Turntables can be designed to handle an imbalanced load.

When a servo motor can’t handle the job, an AC induction gear motors can handle the torque and precision requirements of the application. Applications with higher capacities, exacting positioning, or other non-standard requirement, a gear motor using inverter or VFD control tailors the motions to your requirements.

Upenders: Controlled Work Positioning

Industrial upenders are found in a wide variety of manufacturing environments handling both bulk materials and transferring components within a manufacturing facility. Enhancing productivity and ergonomic safety, they offer a controlled 90 degree work position. Upenders can be paired with palletizers for efficient placing and can give improved access to bulk bins with a full 90 degree tilt.

This material handling machine is found in die, coil, and mold handling operations. Upenders in these applications hold a large mold or die in the proper position for efficient loading.

General Considerations for All Material Handling Applications

As with any material handling application, selecting motors and power systems should take many factors into consideration. Choosing motors to handle the duty cycle, or number of cycles per hour, will match the motor to the application to avoid overheating and ensure longevity. Evaluating the environment in which the application will operate within is critical. Not every gear motor can operate in an extreme or aggressive environment that is high in temperature, humidity, dust, or chemicals. Assuring the motor is matched to the environment will assure efficient, long operating life.

Efficiency is key. Cycle times keep you on track to meet your operational goals. Choosing the gear motor that matches your requirements will be energy efficient and system efficient. Many AC induction gear motors are compatible with inverter and control systems for seamless operation.

Optimizing motor and power requirements for industrial tippers, palletizers, rotators, and upenders is crucial for enhancing efficiency, safety, and productivity in material handling applications. By understanding the specific needs of each system and considering general factors such as duty cycle and environmental conditions, you can ensure the optimal performance of your material handling operations.

Whether you are searching for a material handling application to help make your operations more efficient or building custom material handling solutions for customers, it’s important to understand the relationship gear motors have to the project requirements. Non-standard applications with special or more demanding requirements require a matched AC induction gear motor.

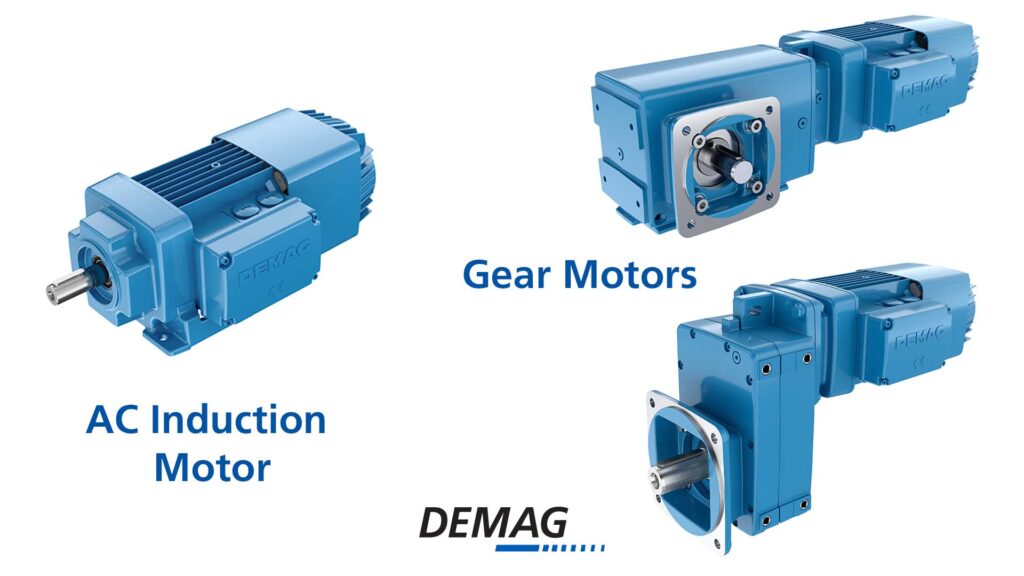

Read more about the wide range of Demag Gear Motors available to meet your requirements and reach out to us for a quote or to discuss your project.

For more insights and expert advice on material handling solutions, stay tuned to our blog.