Determining the right motor to power your next load handling project can be complicated. There are many factors to consider within the project and environment to take into consideration as you decide on how to power the project. Engineering a handling solution and deciding on the components to use is not easy. Every vendor has a slightly different offering of motors that have been tailored to certain situations. Here we will go through the Demag motor offering giving you more information on what type of AC induction motor, also called a squirrel cage motor, will work best for your next project.

Demag KBA Motors

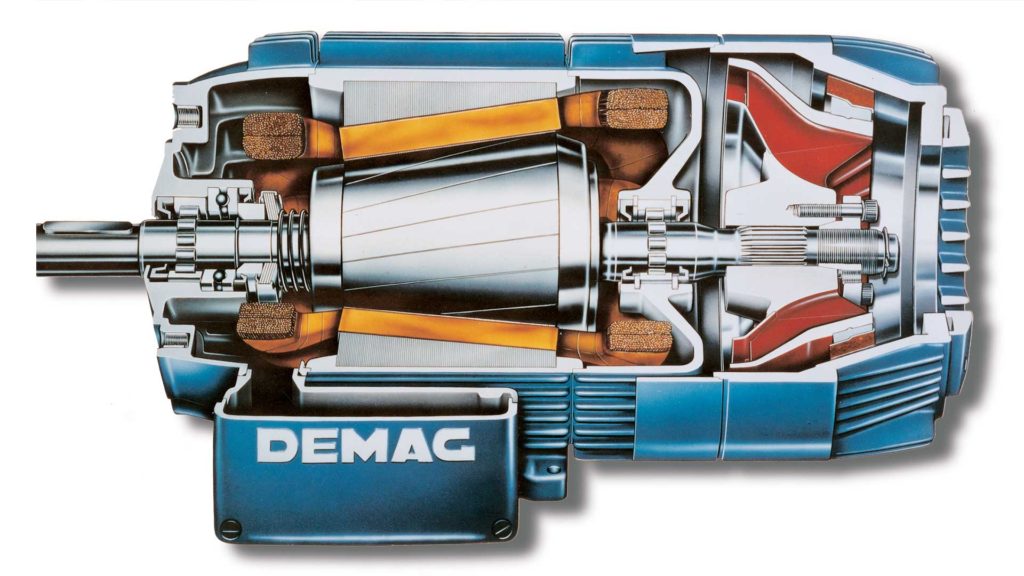

The Demag KBA motor offering is the workhorse specially designed for use in high cycling and precise positioning applications. When you need an AC induction motor that can precisely position or the need for fail safe braking, the KBA motor is adaptable to these unique factors. The motor has a high torque to rotor-inertia ratio allowing it to handle many cycles per hour. The conical rotor motor design creates less heat for efficient operations as positioning drives, drives for rapid cycling indexers and conveyor drives. The KBA has high brake torque which makes it a very precise and efficient choice as a multi-speed drive on machine tools and slewing and rotating on machine drives.

Conical rotor motor difference.

The conical rotor design, or squirrel cage motor design, is able to produce simultaneous starting and braking release. These motors are self-braking meaning the rotor and brake are located on a single shaft. When power is put to the motor, the cone shaped rotor creates an axial force which overcomes the brake spring and allows the rotor to spin freely. As soon as the power is removed from the motor, the axial field collapses and the brake spring forces the motor brake to engage. This eliminates the heat produced in a conventional motor and brake setup. Heat is also eliminated due to the sliding rotor design which eliminates the need for separately energized coils that create more heat in a conventional setup.

The conical motor design also creates the fail-safe braking needed for projects. If the motor is switched off or power is cut off to it, the magnetic force within the cylinder collapses and the motor is mechanically brought to a standstill with the force of the brake spring. This makes the conical rotor KBA motor is very reliable.

Demag KBF Motors

When you’re building material handling solutions like overhead cranes, the Demag KBF travel motor is a reliable solution for controlled acceleration and deceleration of loads. This is also an ideal AC induction motor for transfer cars. The motor has low torque winding and high inertial to provide soft and controlled starts and stops. These output characteristics are also an ideal choice for conveyors requiring the soft start and stop. The conical rotor, or squirrel cage, motor design and high slip design make it a superior choice when multiple motors need to share a load. Typical AC induction motors provide rapid acceleration using high torque and low inertia for quick starts and stops. In certain applications, this can create issues like spinning wheels and swinging or dropped loads. The KBF motor has been specifically designed to reduce both acceleration and deceleration rates for smooth, reliable load handling. The Demag KBF motor is an ideal solution for nearly any material handling need including overhead and rolling conveyor drives, slewing and rotating machine drives, and drives for reverse operation.

Demag Z Motors

There are many general-purpose motors with inverters out there for load handling. The Demag Z Motor is a cylindrical rotor motor providing reliability and efficiency for a wide range of projects. A wide range of motor sizes are available, which have been designed specifically for travel applications with inverters, line-fed travel applications, and applications for nearly continuous duty. This general-purpose motor will give you the reliable braking and operation you need for your next project.

When you are designing a handling solution, there are many motor solutions available in the market. Doing your research and learning about how the motors work and what advantages each has is key to a successful project.

Learn more about Demag KBA, KBF and Z-cylindrical-rotor motors on our website!

Let Demag engineers help you with your next project. Contact us today!