In any production facility, maximizing uptime and minimizing downtime for equipment is key. You have maintenance experts on staff or call in your trusted crane technician who are there to save the day when a machine or piece of equipment is down. Having these experts also gives additional assurance that equipment is running properly so your workforce is safer. Arming them with the right spare parts for the cranes and hoists in your facility can make the difference. Your list may be different based on the age of your equipment or status of your last inspection, but keeping critical spare parts on hand, like those that are common wear items, can help minimize your downtime and get you moving again. Here, we go through the critical parts you may want to keep on-hand.

Spare Pendants and Remote Transmitters

Pendants and handheld radios get a lot of use! This is the operator’s lifeline for using the crane and they receive a lot of abuse from day-to-day use. Many dangling pendants have been snagged by a passing a forklift and handheld radios accidentally dropped one too many times. In many cases, pendants can serve as the primary back up to the handheld radios so if this makes sense for your crane or hoist, keep a spare pendant on-hand.

If you are using the Demag DRC10 radio, a spare transmitter can be easily put into service with a few coded button pushes. A single spare transmitter can serve as a universal replacement for any other similar model running the same frequency. Facilities that have many remote-control cranes can benefit from keeping a single extra spare transmitter.

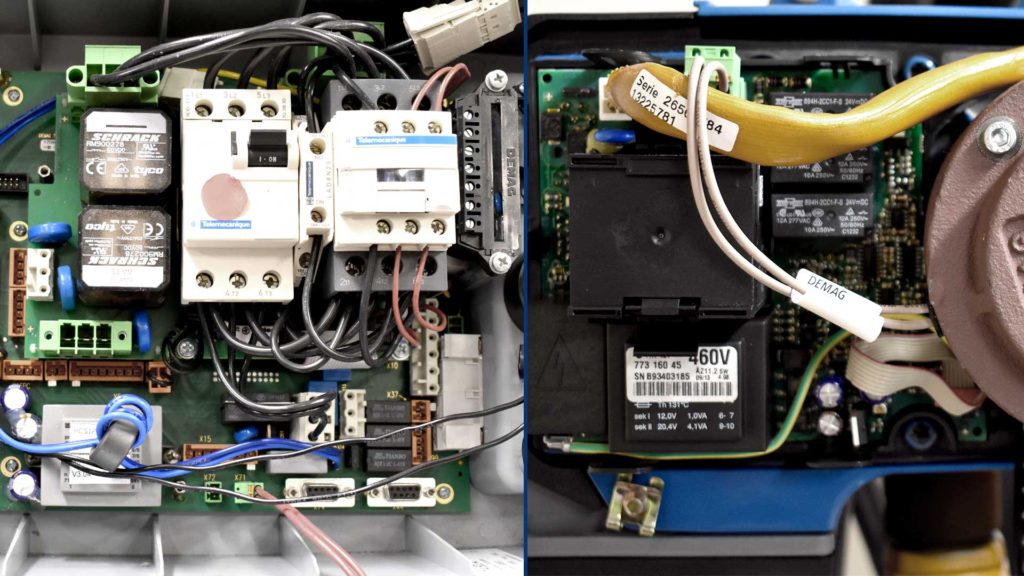

Control Boards and Modules

Control boards and associated electronic modules are found on various pieces of Demag equipment from 1995 on. Most have computerized controls that optimize cycle life of contactors and relays. For chain hoist models, the intent is to changeout the entire board with a new one. For wire rope hoists and associated cranes equipped with IDAPSY controls, complete control boards are available and changeout can be completed in under an hour by an experienced technician. Modules with only the relays and contactors are available at lower cost and usually cure the issue.

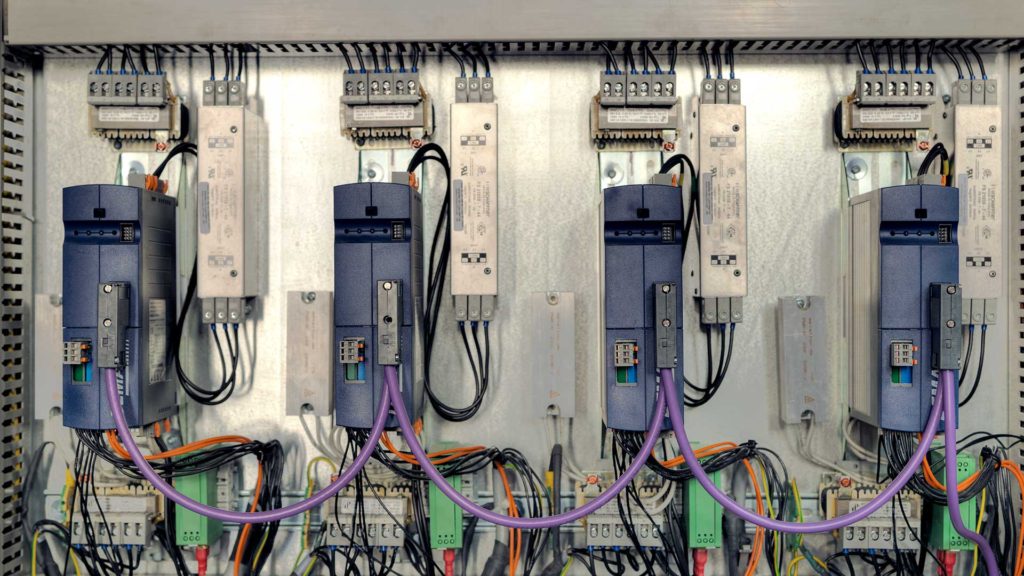

Inverters

Variable speed equipment relies on inverter drives to produce the necessary control signals. These are typically self-contained units with their own internal processor control. Demag offers the DE Drive branded product, but a product from another prominent inverter manufacturer may have been used in the original design. Since an inverter is a specialized electronic unit, local repair is highly unlikely and shipping to a repair center typically takes days to weeks. Keeping an extra inverter on hand allows you to replace the unit immediately while the other is out for repair.

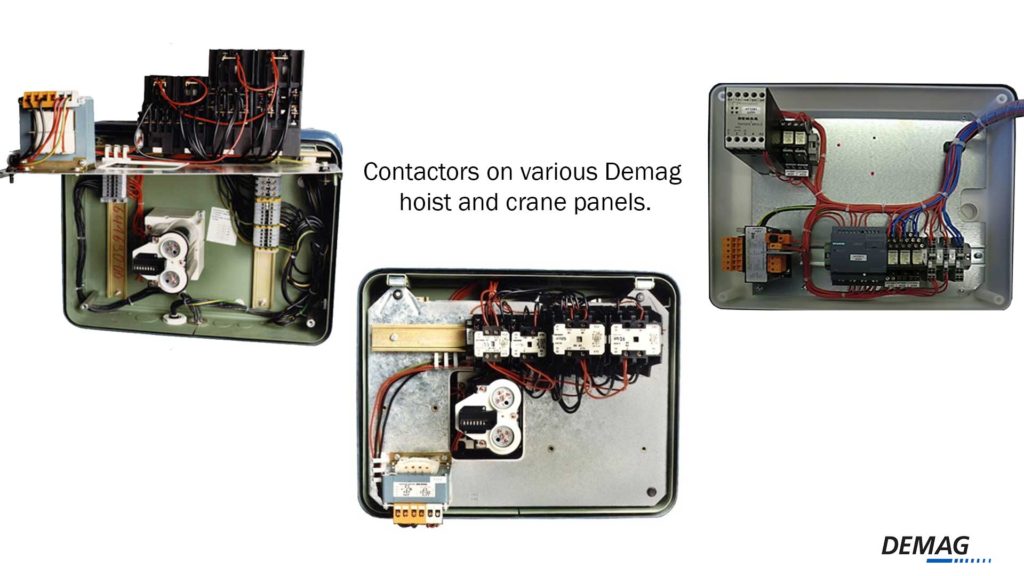

Contactors

Even without computerized controls, contactors are good to keep on hand for conventional 110vac systems. All electrical switchgear has a cycle life. Operations requiring high cycling of the control pushbuttons will achieve their maximum life in a shorter time comparatively. If your equipment is high cycling, keeping spare contactors on hand allows you to avoid waiting for parts shipments.

Fuses

When failures occur on any electrical components, many times the associated fuses provided to protect the electrical circuit will be burned out. Broken and crossed wiring may also cause a fuse to blow. During the troubleshooting process, additional fuses may be blown, so every type and size fuse found in the equipment should have multiple spares available.

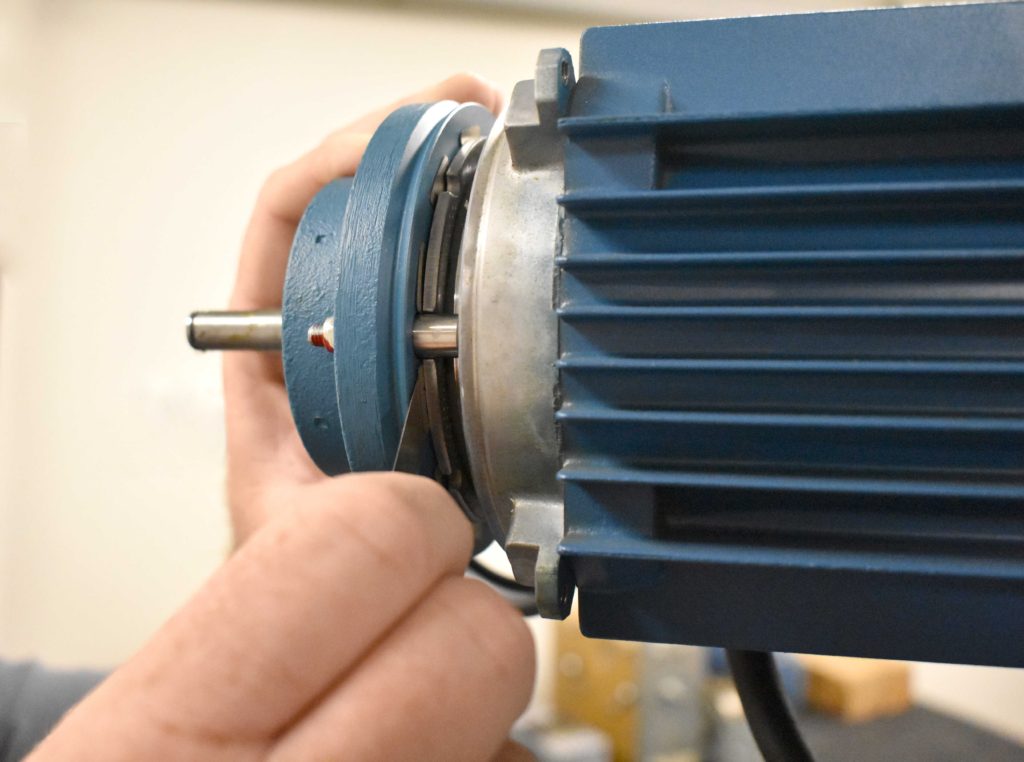

Brakes

Brakes for hoist and travel motors experience wear with use. Two-speed equipment experiences wear every cycle and eventually requires adjustments be made. Typical brake linings allow for 3 adjustments during their useable life, though eventually the lining material becomes too thin and replacement is required. Replacement brake parts vary between motor types, so keeping an extra Brake Ring or Wear and Tear Set as a local spare avoids the wait for shipment.

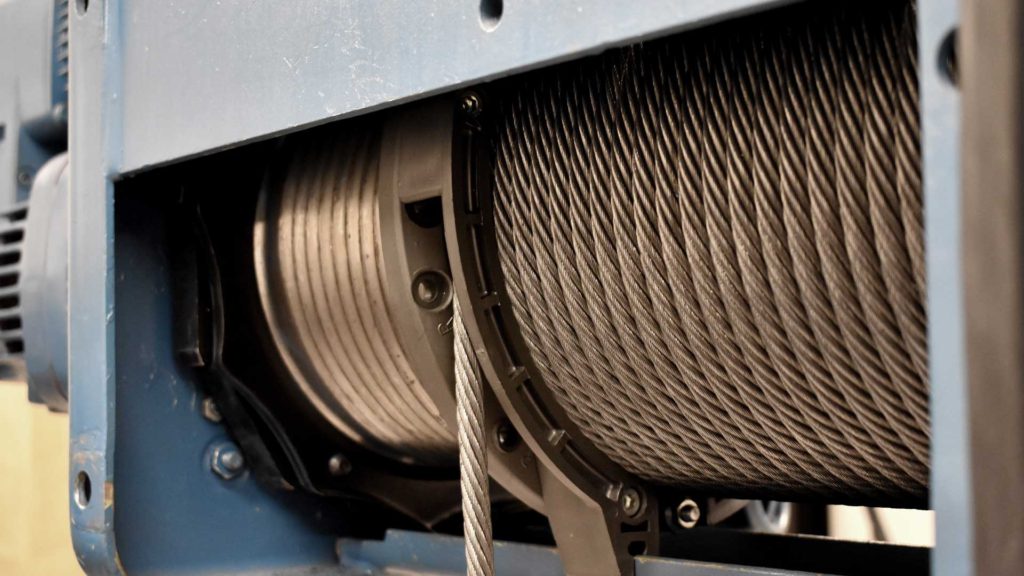

Wire Rope

Wire rope is a machine in itself. It attaches the bottom block and load to the hoist drum. Made up of several individual wires, the rope is constantly stretching, adjusting and flexing when under load. It is also being wrapped around the drum and passed over sheaves in most hoist systems. Even in ideal conditions, wire rope is subjected to abrasion on the outer wires and potential fatigue so wire rope wears with use. If a shockload, kinking or other mechanical damage would occur, the rope could become deformed quickly and require immediate replacement. Keeping spare wire rope on hand allows you to replace the rope without the wait.

Being prepared with having critical spare parts on hand helps you minimize downtime and keeps your workforce lifting safely. Keeping the key spare parts on hand for your equipment allows your maintenance technicians or crane technicians get the job done without the shipping wait. Ask your trusted crane technician what critical spare parts he or she recommends for your equipment.