A common question we get at Demag is how to check crane brake adjustments on our end trucks. In this article, we will go through how to check the adjustment of ZB brakes on trolleys and end trucks to ensure they’re working properly.

Modern era Demag trolleys and bridges provided after 2001 are typically powered by ZB motors. The “B” in “ZB” means that the brake is integrated into the motor. These brakes require an airgap check as part of periodic inspection, and more frequently when used heavily.

What are the visible signs of brake wear?

Operators will report that the crane is coasting further than they are used to. Safety codes and standards require cranes to stop in a distance based on 10% of the rated load speed in feet per minute. For example, typical Demag floor operated cranes with pendant control run at speeds up to 160 feet per minute (fpm) so the maximum stopping distance with a full load must be less than 16 feet. In fact, if the brakes are properly adjusted within their ranges, the stopping distance will be even less than that. The proper way to measure brake wear is to check the brake airgap. This should be measured by a trained technician, and adjustments or replacements made if needed. When the trained technician checks the brake disc, he may find the disc overheated (below left) or severely worn (below right).

What are the most common brake malfunctions for ZB motors?

The brake design for a ZB motor rectifies AC current to DC to energize a brake coil called the magnebody. The rectifier module can burn out, and so can the coil in the magnebody.

Can an operator see any indication that the brake is malfunctioning?

If the brake fails to energize and release when the motor is driven, the motor can drive right through the set brake. While this makes some systems appear to run slower than normal, sometimes this is not noticed. The operator may see smoke or sparks. If it is not noticed, then the brake experiences rapid and severe wear and overheating.

Is there an average or expected life span of a brake before it’s expected to fail?

It’s hard to estimate the life span for these brakes because the time frame to failure depends on usage. The number of movements per hour and the finesse of each operator can play a role in the life of the brake.

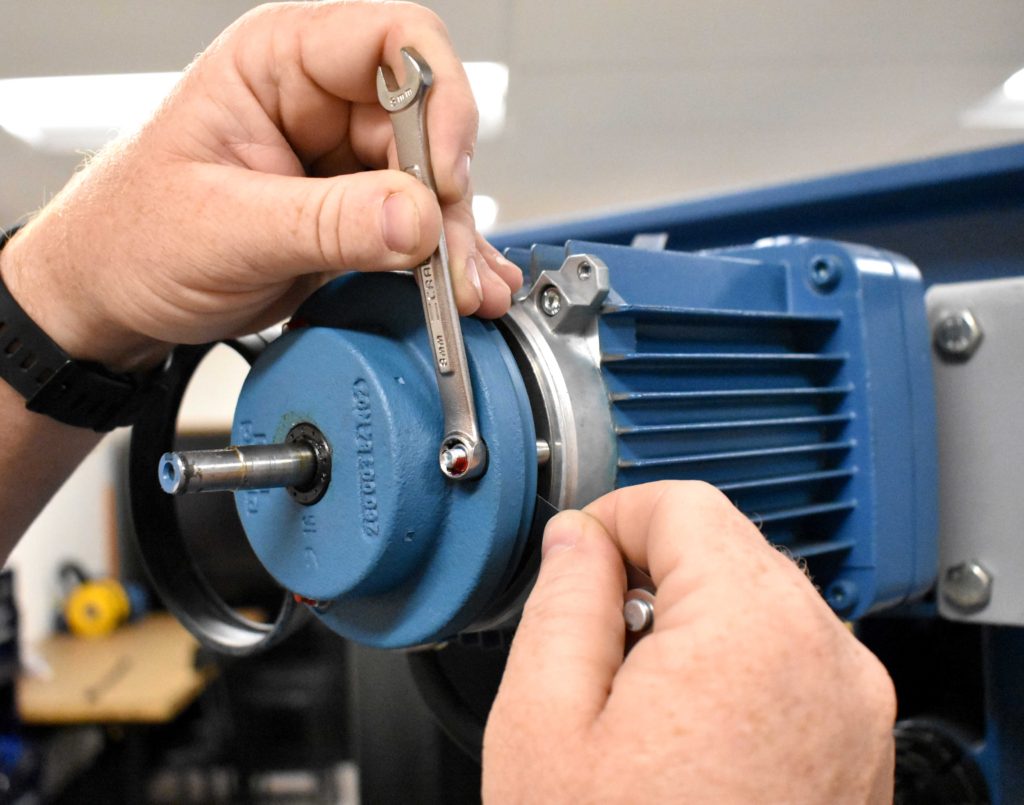

What is the basic procedure for checking a ZB brake adjustment?

First, remove any load before working on the brakes. Next, check the airgap between the magnebody and the back of the pressure plate. Compare the airgap to the allowable range as published in the tables found in the Operating Instructions. The remaining brake disc thickness must also be checked and compared to published tables. If the disc is thinner than the minimum allowed thickness, the brake must be replaced.

What is the basic procedure for making a ZB brake adjustment?

Tighten the three nuts until the brake gap is zero, and then loosen them slightly to create the published minimum air gap found in the table. Check the air gap with a feeler gage all around the circumference to make sure it is even and consistent. Finish by replacing covers.

Tighten the 3 nuts on the pressure plate until the brake gap is zero, then slightly loosening them to create the published minimum air gap found in the table of your owner’s manual.

Why is it necessary to adjust the air gap?

The required airgap adjustment ensures that the brake will close properly and stop a load in the designed range of deceleration and in the permissible distance. It will also allow the brake to release properly and not drag when the motor is running. Checking brake wear in Demag ZB motors is part of your regular maintenance. Operators may see signs of brake wear before the maintenance interval. Always consult a qualified technician when completing any maintenance to your crane.

Use our distributor locator to find a Demag partner in your area to assist you with the service of your crane!