Background:

Manufacturing in the automotive industry is dynamic. Companies are constantly striving to produce components more efficiently with the highest level of workforce safety. Especially in an assembly line process with conveyors or machinery, finding the right solution can help minimize manual lifting and make a safer, more efficient area for your workforce.

Challenges:

A manufacturer in the Automotive industry came to Mid-State Material Handling Inc. in Grand Blanc, Michigan for a light crane system to optimize their component assembly line area. The current area was cluttered with pallets and equipment in places that didn’t allow tow motors and pallet jacks to easily access the area. With so much clutter, there was no room for the tool boxes and equipment needed to assemble the components. The workforce had to walk outside the work area to gather the tools needed. In addition, the workforce in this area was manually lifting components up to 75 pounds. Another aspect to the challenge the manufacturer presented was the need to have an adaptable system that could be easily moved when changes to their processes were made.

“The company came to us because they needed to provide a safer work area for the workforce,” said Aaron McIntosh, owner Mid State Material Handling Inc. “In order to make the area safer, they needed to have open space to drive tow motors and other equipment into the area. Demag had the KBK Light Crane Cantilever Workstation System, which was a perfect fit to meet these needs.”

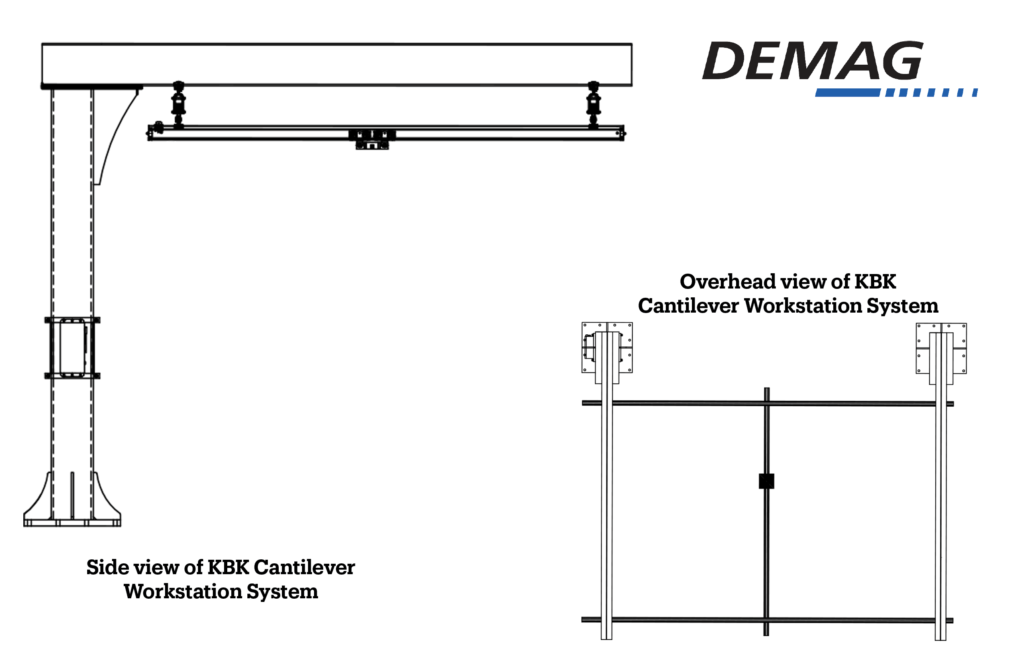

Engineering drawing of the freestanding cantilever workstation system

Results:

The Cantilever system met the needs of this manufacturer in many ways. Since the system is supported by columns and attached to the footers in the floor, the system is deployable with future process changes. Because it has one fully open side, eliminating the support columns on one side, it’s easy to move equipment in and out of the area safely. The light lifting system virtually eliminated the manual lifting process on the assembly line. Now that the area was easily accessible for support equipment and manual lifting virtually eliminated, the area underneath the crane system could be organized to bring in necessary tool boxes and carts so the workforce could have easy access. All these steps made their assembly line area more efficient and safer.

“The added bonus to the manufacturer was lower cost due to the system being freestanding,” said McIntosh. With crane systems suspended from the ceiling, the process involves many more people and resources. A freestanding light crane system, like the KBK, eliminates the need for an architectural engineer to evaluate the structural steel of the building and any costs incurred with changes that come with design alterations along the way. “In addition, a crane system installed in the ceiling cannot easily be redeployed,” said Chad Donahue, Demag District Manager. “I knew the KBK Cantilever Workstation System would meet their needs because it’s so flexible and can grow with the ever changing needs of our customers.”

Learn more about Mid State Material Handling Inc at http://www.msmh.net/.