Whether you’re designing transport, feed, die handling, mill equipment, transfer or distribution cars for moving light or heavy weight loads, it’s important to have a solution that is cost-effective and simple yet lasts and provides the efficiency you need. If you’re an engineer who builds these transfer cars, you know how technical it becomes when you need to take into consideration the wheel and drive specifications from different vendors. Demag’s LRS Wheel Block System is versatile and can help simplify your next project.

Versatility

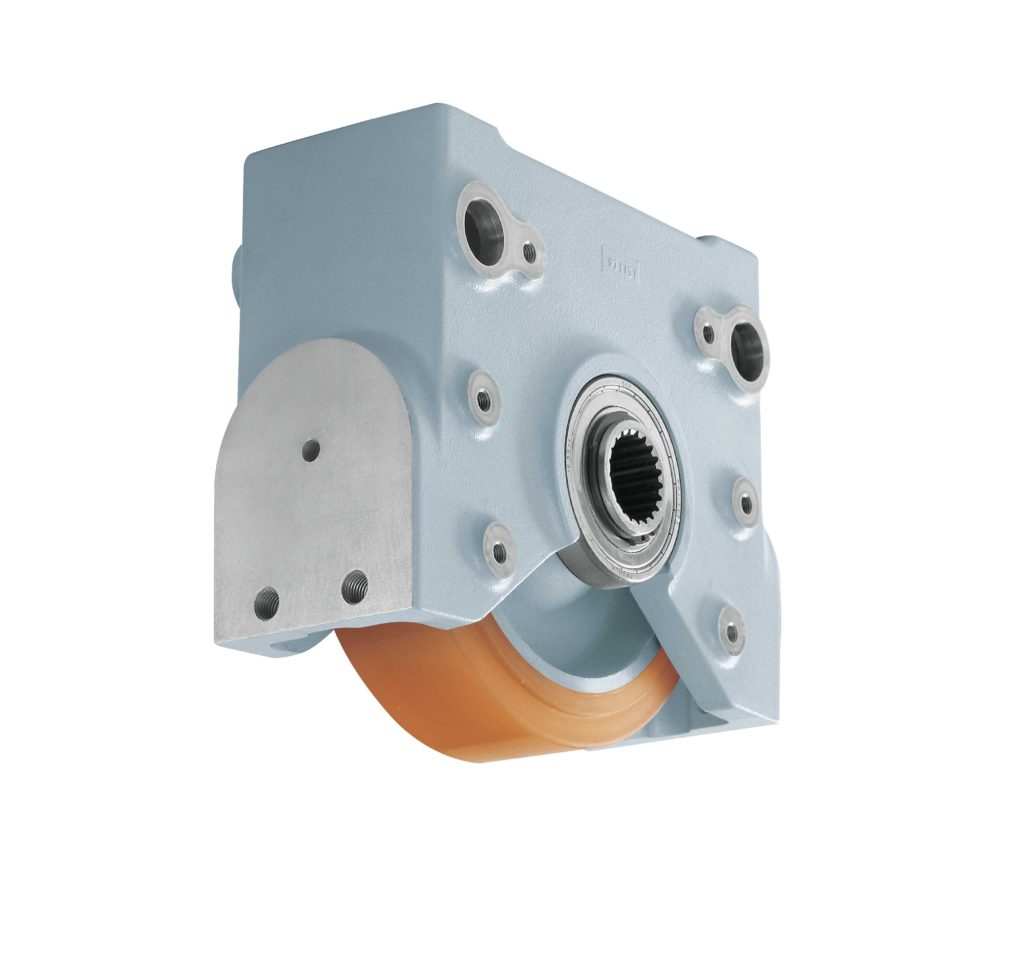

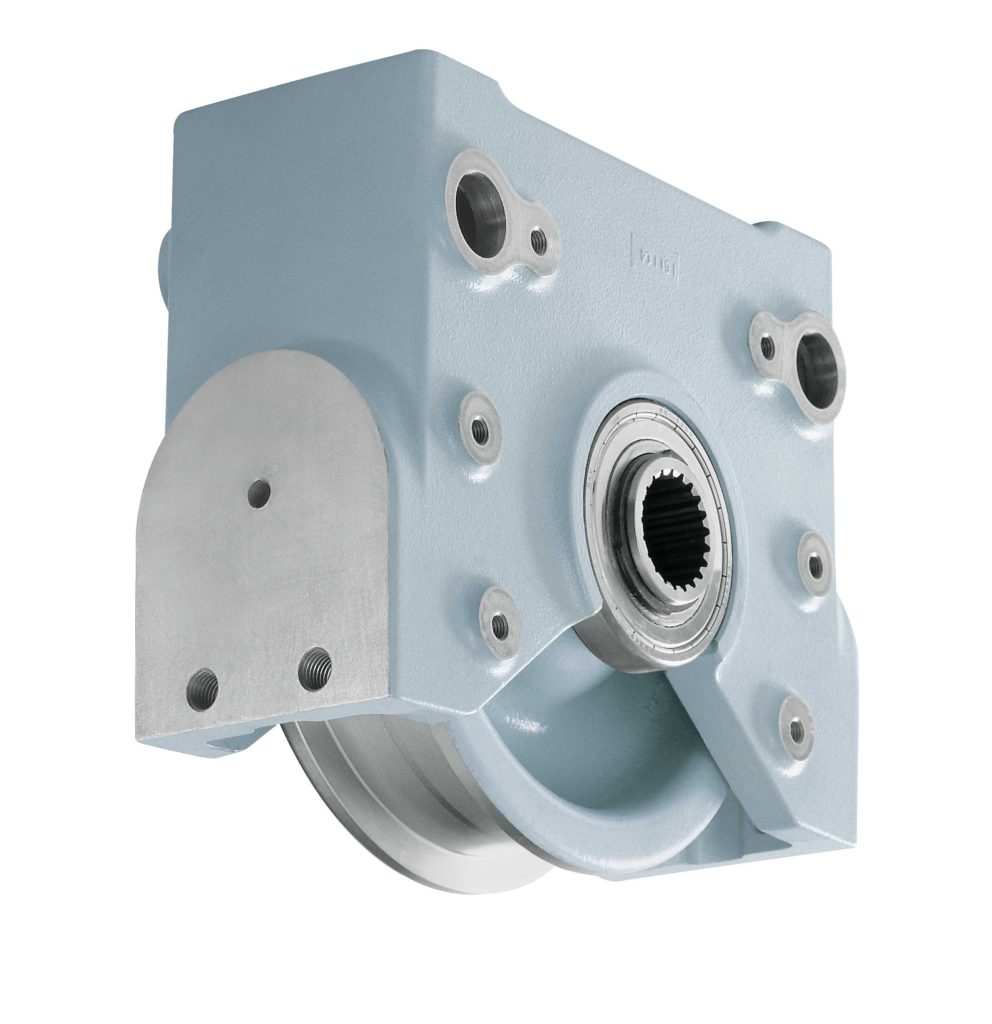

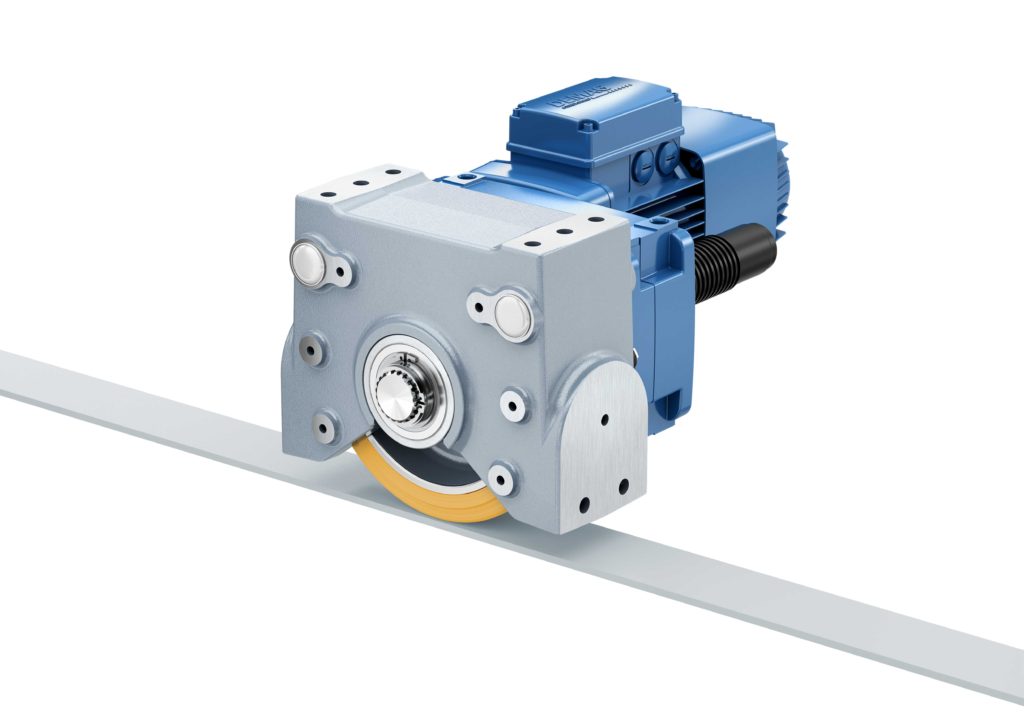

Demag LRS Wheel Blocks are adaptable for a wide range of material handling travel needs. With sizes available to handle a load up to 14,000 pounds per wheel block, it can be configured for use in either manual push or motorized applications. Due to its modular design, the LRS Wheel Block can be matched with one of Demag’s gear motor combinations to create the optimal solution for your needs. Since most rail-guided, ground-level travel units have very low clearance, it can be a challenge to add a motorized option. The modular design of Demag components are designed to allow you to easily do this and as your needs change−effectively add to the existing wheel block or trolley set up. This is the benefit of working with one vendor.

Transfer Cars Retractable Roofs and Coverings

Simple

When you’re looking for a wheel block that is a hard worker, the LRS is the practical, money-saving solution. It’s an ideal option for any project that has constant, repetitive motion. All the components you need are matched and produced by Demag so you know they will work together seamlessly. It’s easy for your engineers to build the solution you need using the matched components from our stock. This eliminates the need for additional engineering time to determine how various components could work best together.

LRS with Hydropur tire LRS with flanges LRS & gear motor

No-Fuss Installation and Maintenance

Installation is easy with the Demag LRS Wheel Block solution. Its modular design and precise surfaces make installation effortless. Maintenance is a vital consideration when selecting a wheel block solution. The LRS wheel block is virtually maintenance-free during its lifetime due to its patented bearing/wheel design. If a unit does need to be replaced at any time, inserting the new unit is easy. Its precise surfaces eliminate time-consuming realignment of components. Simply use the centering bore holes in the top connection or pin connection to align and replace the unit.

Partnering with a singular vendor when building material handling solutions for floor running applications can be beneficial. Not only does it help streamline engineering time, but your solution will be easier to maintain and adjust as your needs change. The Demag LRS Wheel Block System is adaptable for nearly any application and a trouble-free investment that will last.

Want more information or help with a quote for your next project? Click here to send us a message!