The material handling space is vast, and there is a way, or many ways, to efficiently handle nearly any load. Demag is well-known for overhead lifting cranes and hoists, but we also specialize in the travel components used on nearly any material handling project. In this post, we will be looking at how stacker cranes are used in material handing applications and the requirements you may have as you evaluate your next project.

Lifting with a Stacker Crane vs. an Overhead Crane

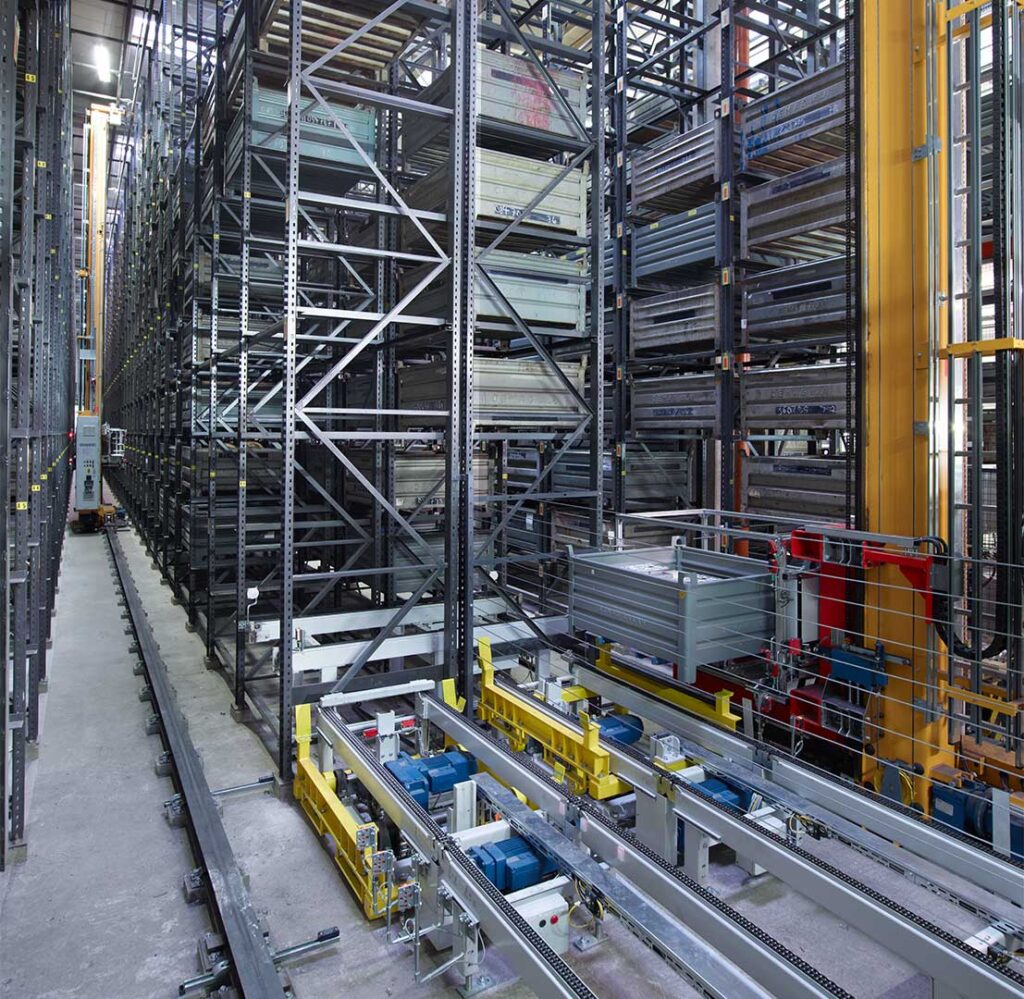

A stacker crane is an overhead lifting device found in warehouses and other storage facilities. These devices move goods, materials, and equipment from one place to another. Stacker cranes may be used in conjunction with overhead traveling cranes.

An overhead traveling crane consists of one or two girders that travel on an overhead runway and use a hoist for lifting in the crane area below. Commonly found in manufacturing applications, overhead cranes are flexible enough to meet a wide variety of lifting requirements. In contrast, stacker cranes travel along rails on the floor to a location. They are a mast or column system equipped with grippers or other load handling devices to retrieve an item.

Stacker Crane Applications

Stacker cranes retrieve components from storage areas. These storage areas can be located in a traditional warehouse or another other type of warehousing location. In AS/RS applications, stacker cranes can work hand-in-hand to retrieve items in the high warehouse shelving for transport to the delivery location.

Other applications stacker cranes can be found are in paper and metal coil or industrial die storage areas. The die or coil is retrieved by the stacker and then placed on a transfer car to be delivered to a set location. A stacker crane eliminates the use of forklifts to complete the task and can eliminate an operator, making the operation safer.

In the automotive industry, stacker cranes can have a variety of uses in the manufacturing process. They can be used for die retrieval in stamping plants where components of an automobile are pressed. Stacker cranes can also be called up on for die retrieval or even pouring molten masses for casting applications. You may also find a stacker crane as part of the manufacturing process where it supports the vehicle body as components are added onto it.

Requirements of Stacker Cranes

When evaluating the requirements for your stacker crane application, you’ll be examining many steps of your process. You’ll be evaluating the travel range of the stacker crane, weight of the item being picked, physical size of the items being picked, and more. Just as with any lifting project, working with an experienced manufacturer or dealer will ensure your requirements are met.

A stacker crane for heavy or bulky loads may be configured with a single or double mast. A common application requiring double columns would be a pallet stacker crane. This supports the capacity of the load and provides a place for a bulky load to sit during transport since it can be carried in the cradle area. Just as with single- and double-girder overhead cranes, the capacity of the items being retrieved may dictate a double-column configuration.

Lighter loads may be configured as a single-column stacker crane. This configuration is commonly found in many warehouses, especially in AS/RS solutions. A single-column stacker crane may use a special gripper or tool to retrieve the material. The specialized tooling can be dictated by industry or product, for instance a stacker crane that is picking coils of paper or metals, or an industrial die retrieval stacker crane.

FAQs About Stacker Cranes

Let’s take a look at some commonly asked questions about stacker cranes and our team’s insights.

What are some of the benefits of using stacker cranes?

Stacker cranes feature many benefits, but their most prominent one would likely be their role in automated operations. Since these cranes are able to work on a nonstop basis, material flow and efficiency increases significantly. This provides for added productivity in your facility.

Additionally, stacker cranes are ideal for fully optimizing a facility’s space, as they can move objects of variable heights and within fairly narrow aisleways. These attributes make them optimal for many different types of facilities.

How do stacker cranes compare to traditional forklifts?

Forklifts can be beneficial for material handling, but there are some ways that stacker cranes stand out in comparison. For instance, stacker cranes can maneuver within narrower aisleways than forklifts do, making them more versatile within facilities.

Additionally, since stacker cranes operate on rails, their paths of operation are clearly delineated, making it much less likely that accidents or other problems can occur, as workers within a facility know exactly where materials will be moving from and to. Such delineation is not always clear with materials being transported via forklift.

What are some common types of stacker cranes?

Some standard stacker cranes include:

- Single-mast stacker crane – Utilizing a single, upright mast, this stacker crane is often used for handling pallets and containers of various types

- Double-mast stacker crane – The double-mast construction of these cranes allow them to carry bigger loads and attain greater heights

- Bridge stacker crane – Using a bridge structure for horizontal movement, these cranes are ideal for optimizing space within a facility

- Satellite stacker crane – These cranes are part of satellite AS/RS systems, with numerous storage shuttles being used within facility aisleways and the cranes fulfilling the roles of transfer devices

- Mini-load stacker crane – For smaller material handling needs, mini-load stacker cranes are ideal, with these compact units being well-suited for navigating narrow aisleways

- Multi-deep stacker crane – These cranes are adept at reaching and retrieving loads from a variety of positions inside a solitary storage area or lane

How do stacker cranes contribute to sustainable warehouse operations?

Stacker cranes often are lighter weight than other material handling options, reducing energy consumption by a notable degree. Additionally, some cranes feature regenerative energy features and integrated energy management systems, both of which can reduce energy consumption and allow operators to better control and monitor energy output.

Get Precise Positioning for Your Stacker Crane

You’ll need to determine how precise the crane needs to be in every step of the process. The amount of precision required can be dictated by what you are retrieving and what type of gripper or handling device is being used.

Ultimately, the precision of your stacker crane is dependent on the AC induction motor and gearbox combination being used. The motor creates RPM and the gearbox translates that RPM into torque. Torque is used for both travel and braking purposes. Position accuracy is creating the right brake torque so your stacker crane stops in the right place with the correct braking tolerance. Read more about how the gearbox in our gearbox basics post.

Stacker cranes retrieve goods in traditional warehouses and other warehousing locations. Commonly used in AS/RS solutions and industrial die and coil retrieval, stacker cranes are customized to your exacting needs. Whether you require a single- or double-column design with precision positioning, Demag has the motor, gearbox, and wheel solutions to meet your needs.

Choosing a vendor partner to supply your operations with the right solutions is critical. Demag partners with vendors who build stacker cranes for end users and with material handling dealers who create these solutions. Choose a vendor who can provide you with a complete solution.

Contact Demag Today for Stacker Crane Components

Need quality and reliable stacker crane components for your operations? Reach out to the experts at Demag. We can assess the needs of your facility and deliver the right equipment for the job.