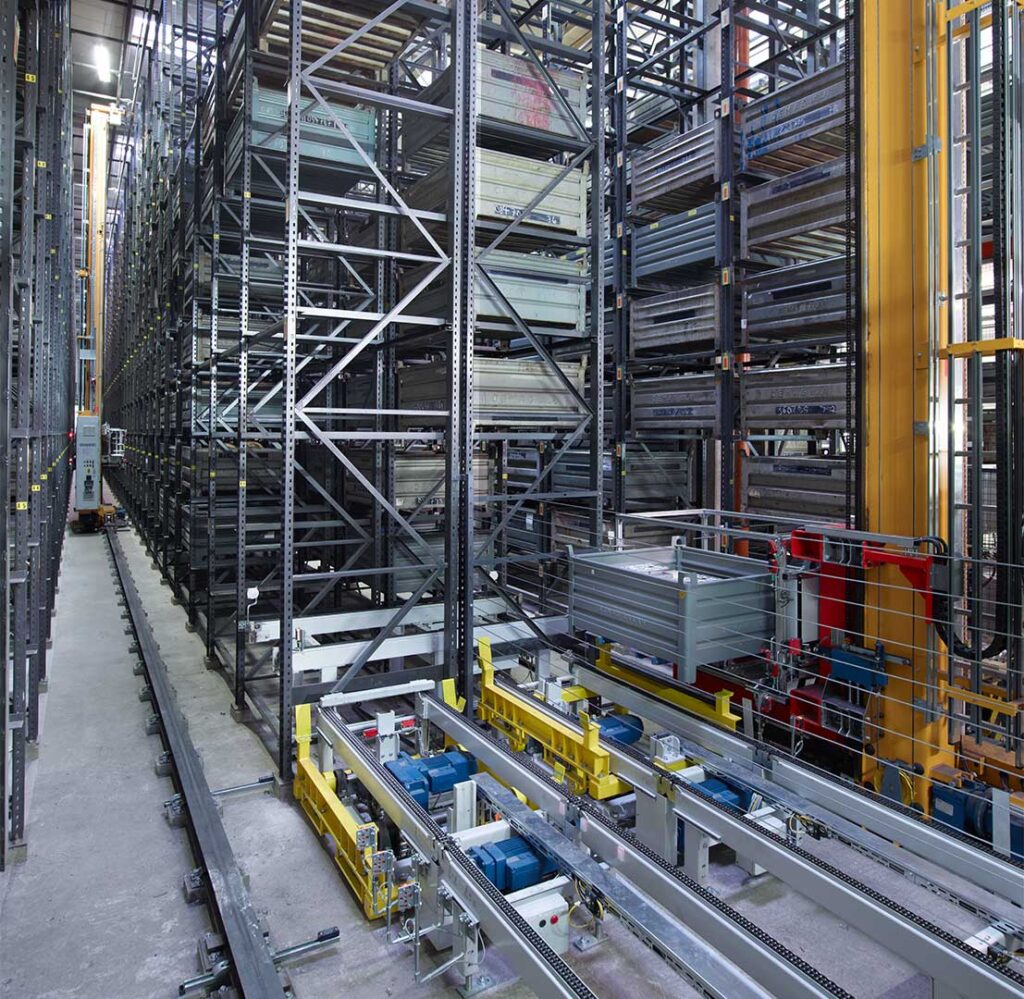

Automated storage and retrieval systems (AS/RS) found in distribution and manufacturing facilities enhance accuracy, efficiency, and productivity. These systems are known by a variety of names like dynamic storage systems, goods-to-person picking technology, or high-density storage and retrieval systems. Regardless of the name, AS/RS systems can bring benefits to your facility. Read on to learn more about AS/RS systems.

How an ASRS System Can Benefit Your Facility

Automated storage and retrieval systems save floor space in distribution and manufacturing facilities by using large areas of shelving that do not require the use of forklifts and lift trucks. There are many companies that have a standard system that can help meet standard requirements. There are also material handling dealers and companies who custom engineer solutions. No matter which solution works for you, AS/RS systems are comprised of a few major components. These include the storage and retrieval equipment, input/ output system, storage rack, and software system.

Types of Automated Storage and Retrieval Systems

The two common types of AS/RS systems are unit-load and mini-load systems. A unit-load system can handle a large load like a full pallet or case. A mini-unit load is similar, handling smaller loads, and may be implemented in spaces with narrower aisles or smaller footprints. Many times, an overhead crane or stacker crane solution is a complementary part of an AS/RS system.

Other systems found in the AS/RS product space are vertical carousel modules (VCMs), horizontal carousel modules (HCMs), vertical buffer modules, and floor robots like AGVs and AMS. Many AS/RS systems travel on a track to retrieve and deliver items. Floor robots and AGVs can give more flexibility to the solution, even eliminating the need for a track. Working with a knowledgeable material handling manufacturer or dealer will allow you to find a solution to meet your needs.

Hardware Components of an AS/RS Systems

Software and the AS/RS hardware work hand-in-hand to create the solution needed. The software system delivers the instructions and locations of what needs to be picked. With those instructions, the hardware is sent out to complete the task. We are defining the hardware of the AS/RS system to be the units, carousels, or bins that use the motor, wheels, and electrification system. All the components are physically used to deliver the bin to the pick location and back to the delivery location.

Industrial, Uni-Directional Wheels

Since many AS/RS systems run along a track, industrial wheels are an important component. These wheels are uni-directional, meaning they only go forward and backward, with no 360° movement. Most of all, these wheels should support the capacities of the loads and be matched to the environment in which they operate to reduce the amount of maintenance your ASRS system undergoes. In addition, they should require little maintenance and have a long, reliable life cycle.

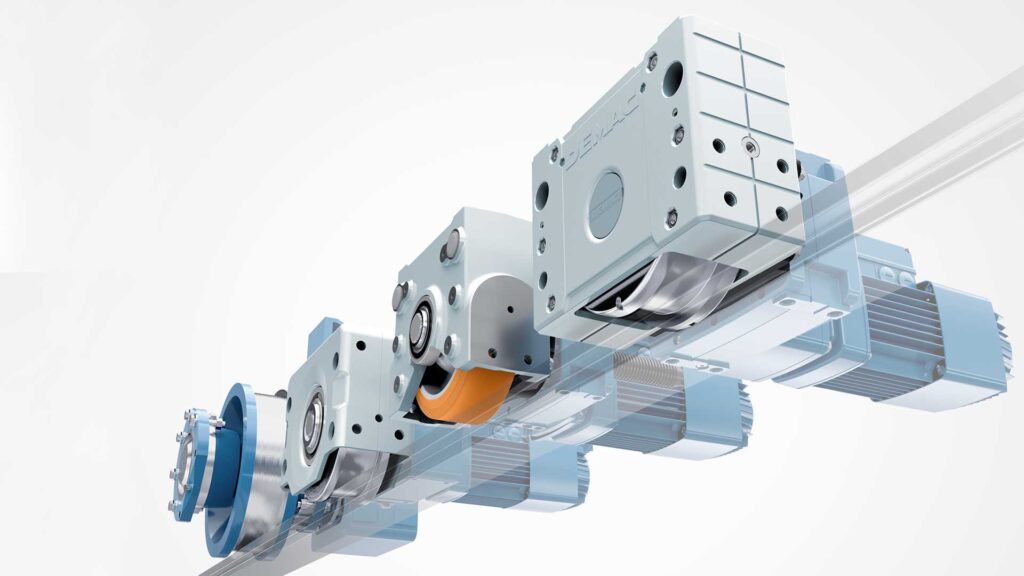

Industrial Gear Motors

Gear motors translate speed to the wheel on the unit, carousel, or bin using a gearbox interface between the motor and the wheel spline. These industrial motors are an AC induction motor in models to meet the capacity, speed, and braking needs of your AS/RS solution. Generally, a cylindrical rotor motor with an external brake will be found in AS/RS solutions. If requirements become more extreme, a conical rotor motor with mechanical braking may be required.

Advantages of a Custom AS/RS System

As your requirements become less standard, a custom AS/RS solution may be needed. Custom AS/RS solutions are engineered to handle many non-standard requirements like irregularly shaped loads, maneuvering within tight tolerances, and optimizing the handling of precise and delicate items. If the AS/RS system will be used in an extreme condition, like a refrigeration or freezer environment, all hardware components need to be optimized to operate within the environment.

Demag Drives Components for AS/RS System Solutions

When you are building standard or customized AS/RS systems for your customers, see what Demag can offer. Our drives components include industrial wheel block systems, geared motors, electrification, and more to create an entire drive system. These modular components are designed to work together so you can be assured of compatibility.

Demag gear motors are available as cylindrical rotor and conical rotor motors. Z cylindrical motors have an external brake and is ideal for solutions requiring VFD. K conical rotor motors have a mechanical brake and can be an ideal solution for use in extreme environments. Both AC induction motor types can deliver a wide variety of speed and torque requirements. Demag industrial wheel block systems can be matched to your capacity and environmental requirements. These wheels are designed to be easy to install, maintain, and replace, especially on your AS/RS systems.

Since AS/RS systems and overhead cranes commonly work hand-in-hand, Demag can deliver a full solution as an overhead lifting specialist. Whether you need a traditional overhead crane with a girder and wire rope hoist or reliable, efficient components for a stacker crane, count on Demag lifting components.

Reach Out with Any Questions You Have Regarding AS/RS Systems

Keep your business moving with an automated storage and retrieval system. These systems can save floor space in distribution and manufacturing facilities while enhancing accuracy, efficiency, and productivity.

As you explore the options out there, make sure you reach out to a knowledgeable material handling manufacturer or dealer so you can meet your unique requirements.