When it comes to lifting heavy loads in an industrial or manufacturing setting, a wire rope hoist is often the equipment of choice due to its strength, durability, and efficiency. This guide will help you determine whether a wire rope hoist is the right solution for your needs and provide you with key considerations for selecting the right hoist. Ultimately, you should consult with an overhead crane manufacturer or dealer to ensure the best fit for your specific requirements.

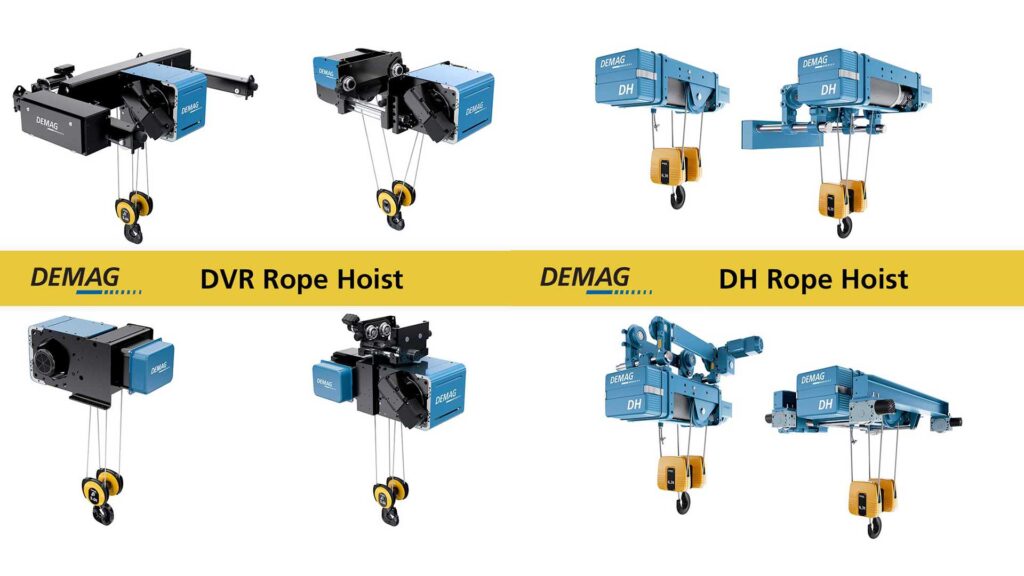

Demag wire rope hoists meet a wide range of requirements in industrial settings. For manufacturing and many industrial settings, the Demag DVR rope hoist will meet your requirements. Lifting loads up to 80 tons, these hoists are productive and efficient for your operations. Add additional options and safety features to tailor the hoist to your operational goals.

The Demag DH wire rope hoist is designed for reliable, safe operation in extreme and aggressive environments. This hoist can handle extreme capacities up to 100 tons and lifts up to 340 feet. It can be tailored with optimized motors to operate in moisture rich, dusty, and corrosive environments. No matter the environment, the DH hoist brings reliable operation in nearly any industrial environment.

Do You Need a Wire Rope Hoist?

Before diving into the selection process, it’s important to assess whether a wire rope hoist is the appropriate tool for your application. Just as with any lifting device, there are many factors to consider.

Load Capacity

Wire rope hoists are designed for heavy lifting, typically ranging from 1 ton to over 100 tons. If your application requires lifting very heavy loads consistently, a wire rope hoist is likely a better choice compared to chain hoists, which are generally suited for lighter loads.

Duty Cycle

Consider how frequently the hoist will be used. Wire rope hoists are ideal for high-duty cycles, meaning they can perform frequent lifts throughout the day. If your operations demand continuous lifting, a wire rope hoist is more suitable than other hoists like chain hoists.

Lift Height and Speed

Wire rope hoists offer higher lift heights and faster lifting speeds than chain hoists. If your application involves lifting loads with long lift heights or requires quick and efficient lifting operations, a wire rope hoist will meet these needs.

Environmental Conditions

It is crucial to consider the environment where the hoist will operate. Environments with harsh conditions like extreme temperatures, moisture rich, and dusty or corrosive environments have special requirements. Wire rope hoists designed for such environments are robust and can operate reliably in these challenging settings.

Choosing a Wire Rope Hoist to Meet Your Requirements

Once you’ve determined that a wire rope hoist meets your requirements, the next step is to gather the information needed so you choose the right hoist. Demag offers two models of wire rope hoists, the DH Rope Hoist and DVR Rope hoist.

Load Capacity and Safety Factors

Determine the maximum weight the hoist will need to lift. It’s essential to select a hoist that can handle the load capacity required to ensure safety and longevity. Manufacturers typically provide a safety margin; however, it’s advisable to consult with an expert to confirm the appropriate capacity for your needs.

With Demag wire rope hoists models, one place to start with choosing between the two models is by capacity. The DVR rope hoist can handle loads up to 80 tons while the DH wire rope hoist can handle loads up to 220,000 pounds.

Hoist Type and Configuration

Wire rope hoists come in various configurations, including stationary, under running, low headroom, and double girder. The configuration will largely depend on the specifications of your application. Both Demag rope hoist models are available in all the listed configurations.

Stationary or Foot Mounted Hoists

These hoists are in a fixed in location. They are ideal for repetitive lifting in a single area or for applications where heavy doors are being lifted.

Under Running Hoists

Hoists are mounted on a trolley that moves along the underside of the girder. This common configuration is suitable for applications requiring horizontal movement in applications where headroom is not limited.

Low Headroom Hoists

Hoists are mounted on a trolley that moves along the underside of the girder but is optimized for applications with limited headroom and envelope dimensions. This common configuration is suitable for applications requiring horizontal movement in applications.

Double Girder Hoists

Hoists are mounted on a trolley that runs along the top of 2 parallel girders for applications with very heavy loads and long spans.

Lifting Speed and Height

Identify the required lifting speed and height for your application. Higher speeds can improve efficiency but may come at a higher cost. Ensure the hoist can achieve the necessary lift height for your application to meet the handling requirements of the components you will be lifting.

For extreme lift heights, the DH wire rope hoist can handle lifts as long as 340 feet. This hoist and the DVR rope hoist can meet more standard lift height requirements in any industrial environment.

Power Supply

Consider the available power supply in your facility. Wire rope hoists are typically powered by electricity and the voltage requirements can vary. Knowing the electrical supply requirements of your facility or the facility a hoist will be operating within will ensure the facility can provide the necessary power. It also ensures the appropriate modifications can be made if necessary.

Controls and Safety Features

Modern wire rope hoists are available with various control options, from basic pendant controls to advanced remote radio systems. Safety features such as overload protection, emergency stop buttons, and limit switches are crucial for safer operations. Discuss these features with the manufacturer or crane dealer to ensure your hoist meets all safety requirements.

Maintenance and Support

Selecting the right wire rope hoist can be complex, given the many variables involved. It’s highly recommended to consult with an overhead crane manufacturer or dealer who can provide expert advice tailored to your specific requirements. They can conduct a thorough assessment of your application, recommend the best options, and ensure the installation is done correctly.

A wire rope hoist can significantly enhance the efficiency and safety of your lifting operations. By carefully evaluating your needs and consulting with experts, you can choose a hoist that provides reliable performance for years to come. Reach out to a reputable overhead crane manufacturer or dealer to get started on selecting the wire rope hoist to meet your application requirements.