Demag wheel blocks are designed to be modular so maintenance and replacement are simpler. Adding them to a complete drive system is simple and engineering the system can even be done by your in-house engineering team. One common question we get is how to tell what wheel block is on a system. Here we will give you some tips on how you can determine what wheel block is on your material handling solution.

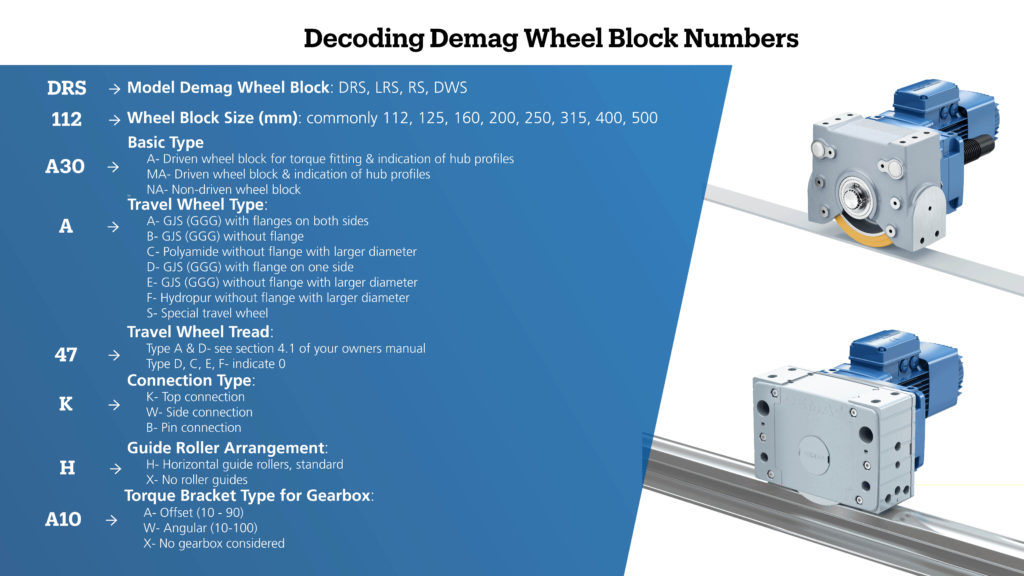

Our drives and wheel block systems can last a long time so it’s not uncommon for us to receive calls inquiring about how to tell what wheel block is on a system when it’s time to replace or maintain one. One of the easiest ways to tell what Demag wheel block is on your application is with the identification plate. Every Demag product has an identification plate that give you important information like serial number, date of manufacture, and model name. Every Demag wheel block has 2 identification plates, one on each end. Chances are, you are going to be able to find one of the identification plates to give you the information you need. When you do, you’ll find a long model number. This model number is packed with information like which type of wheel block is on your application, type of travel wheel, connection type, and wheel size. When you find the identification plate, reference the key above to decode it.

Depending on what the wheel blocks are being used for, sometimes both ends are covered so finding or seeing the identification plate is nearly impossible. There are many applications where the plates are covered by add-on guide rollers or bumpers. You may also come across an older wheel that simply does not have an identification plate, potentially due to someone removing it or the wear to the plate makes it impossible to read. When you come across any one of these situations, you can always reference your documentation. Part of a good maintenance program is having the proper documentation on file. Suggested documents include the operator manual, spare parts breakdown and original paperwork from the install. This documentation makes it easy for you to order any spare parts you may need, determine the proper maintenance intervals, and have a complete history for tracking the age and maintenance completed.

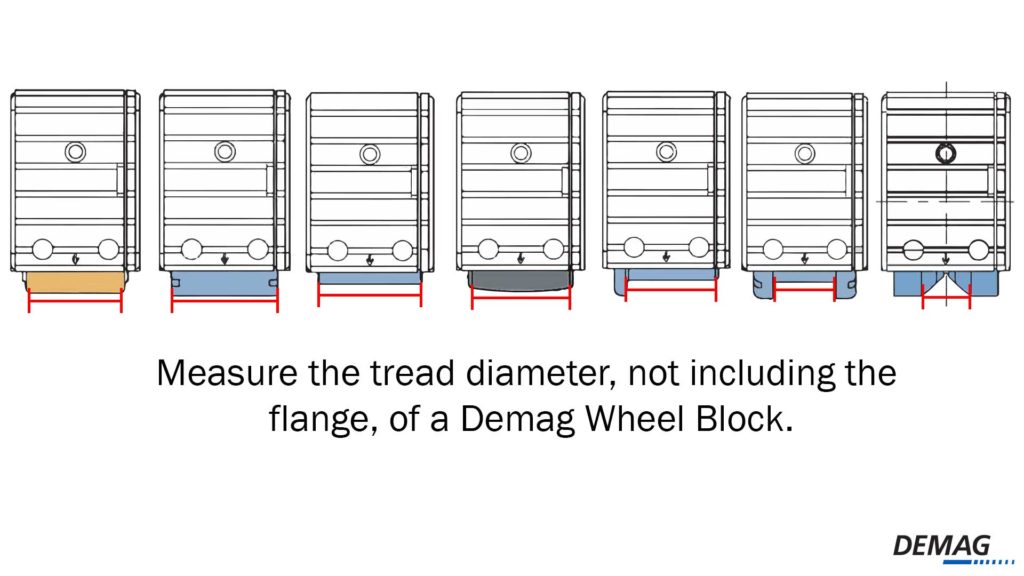

When all else fails, you can measure the wheel tread to determine the size of the wheel. The tread is the surface of the wheel that contacts the rail. Depending on the application, the wheel may or may not have flanges. When you are measuring the tread diameter, do not measure the flange, just the surface of the wheel that contacts the rail. Always take this measurement in millimeters.

Most Demag wheels are one of our standard sizes- 112mm, 125mm, 160mm, 200mm, 250mm, 315mm, 400mm, or 500mm. Some projects require custom machined wheel blocks so there is a chance your measurement would not match any of our standard sizing. When you measure the tread diameter, your measurement will not be an exact match to the standard size. Why? Remember, the tread wears with use so your measurement will always be smaller than the standard sizing. How much smaller than the standard sizing will be dependent on the age of the wheel since the more the wheel is used the more wear it experiences.

When it’s time to maintain or replace a Demag wheel block, the key information you need is contained on the identification plate. Without this information, you can always reference your documentation on file or take a measurement of the tread diameter to determine the size of the wheel. Since wheel blocks can last a long time on an application, having a good maintenance program will assure they will continue functioning safely and properly while giving you the documentation to reference when it’s time to replace them.

Learn more about Demag’s full line of wheel blocks and contact us about your next project!

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- From Customer to Demag USA Technical Trainer - May 9, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023