Manufacturing industries that handle glass and fragile products have unique challenges. The delicate nature of these materials requires precision, care, and efficiency to ensure both product quality and the safety of the workforce. One solution that has proven to be highly effective in addressing these challenges is the use of enclosed track cranes. Here we will explore the risks associated with handling glass and fragile products and highlight the benefits of using enclosed track cranes.

The Challenge of Handling Fragile Components

Manufacturing glass products, ceramics, electronic components, and other fragile materials involves inherent risks in many industries like automotive, aerospace and electronics. Conventional lifting methods often pose risks, leading to potential damages and workforce injury. Mishandling or improper lifting techniques can lead to breakages, defects, and, most importantly, pose a significant risk to the safety of workers. The weight, shape, and fragility of these materials make traditional handling methods both impractical and unsafe.

In many operations, the glass pieces can be large and awkward. This can cause unsafe lifting conditions without ergonomic lifting equipment and processes. If glass is dropped or damaged during the lifting and maneuvering process, production costs increase and employees can be injured. The need for a more secure and reliable solution becomes evident, and this is where enclosed track cranes step in.

Benefits of Lifting and Handling Fragile Components with Overhead Cranes

Enclosed track cranes with lifting devices, like a chain hoist, can add benefits to many operations. From improved precision and control during lifting and positioning to the reduction of breakage and damage, crane systems can enhance efficiency and productivity in the overall production process. It can give the operator more control over the handling and movement of the pieces.

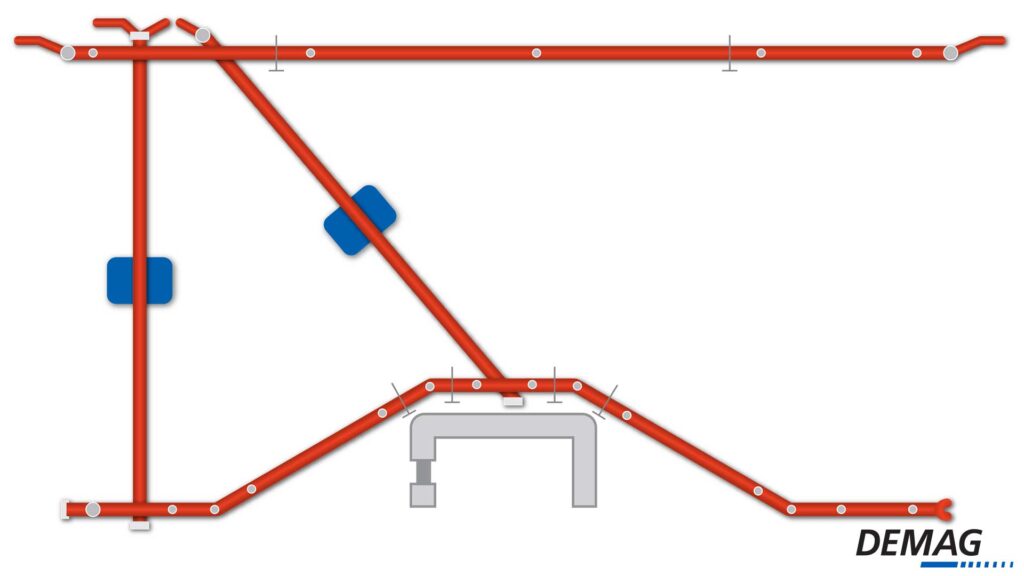

Operators have more control and can make precise movements. The crane and hoist can make motion and maneuvering smooth and precise, reducing the risk of accidental collisions and drops. When handling fragile components, it’s critical the crane solution meets your unique process requirements. Enclosed track cranes are flexible and adaptable, with standard system designs to customized solutions to navigate through confined spaces and difficult to reach areas.

Using a crane and hoist can reduce or eliminate manual lifting and handling in your current processes. If handling glass panels, they can be large, awkward, and require more than 1 worker to properly lift the piece. Using a hoist with end tooling can eliminate the need for manual lifting and potentially allow one worker to perform the lifting task.

This reduces the risk of workforce injuries associated with lifting heavy or awkward loads. Additional safety features can be added to contribute to a safer work environment like overload protection, limit switches, and anti-collision systems.

Features of Demag KBK Cranes for Fragile Glass Handling

Using a crane for lifting and handling requires movements to be fluid and precise. Demag KBK Crane and Monorail Systems deliver smooth, precise motion. Whether you require manual push/pull or electric travel, KBK brings benefits to your workforce. For manual push/pull applications, operators will notice the smooth performance of Demag trolleys. Both steel and aluminum track is coated inside and out, complementing trolley wheels, for smooth running performance and minimum rolling resistance.

Demag KBK crane bridges articulate for optimal ergonomic and handling performance. Articulation allows the operator to handle a heavy load at the end of the bridge without binding. This articulation can allow for angled track sections for lifting and handling in confined, difficult to reach areas.

Using a lifting device to lift fragile products can eliminate manual lifting operations in your processes. Demag offers DC chain hoists and balancers to meet your requirements. With models to lift up to 5 Tons, there is a DC Chain Hoist to meet your needs and your budget. The DC-Com comes with 2-speed lifting as standard and includes an ergonomic, adjustable pendant and pendant cable. As your requirements grow, DC-Pro and DCS-Pro models are feature packed for use in lifting and automation applications. The unique Manulift handle can make fast pick and place processes more ergonomic and precise.

Adding float mode to your assembly, manufacturing, or placement processes can be accomplished with a Demag balancer. Whether you require an electric or air balancer, these models can meet your requirements. The DCBS electric balancer operates similarly to a chain hoist. Easily program additional safety features and give your operators modes to meet their process needs. Standard and programmable modes allow operators to handle, position, and assemble components ergonomically and safely.

The Demag D-BP II Air Balancer uses clean air power. Packed with industry leading safety, the D-BP II balancer can help meet your safety KPIs in your operations. All up/down balancers come standard with Load Weight Compensation, assuring every load, regardless of weight, is handled at the same, safe speed. Base Load functionality prevents operator error when handling fragile components, preventing the operator from exhausting all air from the balancer to prevent load sinking or falling after the component is placed.

Enclosed track cranes have proven to be invaluable tools in enhancing safety and efficiency in the manufacturing processes of glass and fragile products. From improved precision and control during lifting and positioning to the reduction of breakage and damage, cranes can enhance efficiency and productivity in the overall production process. Their precision, flexibility, and advanced safety features make them well-suited for industries where delicate materials require careful handling.

The tools used to lift and handle glass should strive to reduce breakage and damage while improving safety for your workforce. Using a crane and lifting device like a chain hoist can help meet these challenges.

See how Demag KBK Crane Systems and DC Chain Hoists can assist you! Contact us to discuss your challenges.