One of the most well-love Demag products made was the P Hoist. We talk to a lot of customers even today who reminisce about times one was in service in their factory. In fact, we talk to customers who are still using the hoist in their operations even today. If you or one of your customers are still lifting with a Demag P Hoist today, make sure you read this article. We will be talking about the history of the P Hoist, some of the age issues we are seeing when it comes to spare parts, and when you should consider replacing the hoist with a new hoist.

P Hoist History in North America

With more than 200 years of history, Demag has built a lot of hoists. Demag’s first electric rope hoists or winches were developed in the late 1890’s. This paved the way for other electric hoists to be developed. The P Hoist was introduced to the North American market in 1961. Shortly thereafter, in 1966, the manufacturing facility in Wetter, Germany produced the 100,000th P Hoist. It was a very well-loved Demag product throughout the time it was sold across the world. But all good things must come to an end, and the P Hoist was replaced by the Demag DH Wire Rope Hoist in 1986.

Original Design & the 1968 Design Modification

The P Hoist was the first Demag wire rope hoist where the motor or gearbox could be removed from the hoist frame and drum without the need to remove the entire hoist from the crane and trolley. A major design modification took place in 1968 that affected the drive train and involved the shafts and internal coupling. The design change was prompted by the adoption of the FEM code in Europe, which defined and specified duty cycle criteria. As a result, most external parts of the hoist crossover, but the internal design does not.

In addition to the design modifications in 1968, the model numbering scheme was revised as well. The old single- and double-digit model codes (5-80) were replaced by 3-digit model codes (100-2000). It is important to note, the internal drive parts for the pre-1968 design were declared obsolete 25 years later in 1993. Due to this, there is no hope to replace those old parts with Demag OEM spare parts in 2021. When confronted with this situation, replacing the hoist with a newer model may be the only solution. The model life of the P Hoist ended in 1986 with the introduction of the DH wire rope hoist. The DH hoist welded box designs had lesser castings and were easier to fabricate.

Common Hoist Failures Reported with P Hoists

As I write this in July 2021, the youngest P Hoist is at least 35 years old. In many cases, 35-45 years of continuous use exceeds the fatigue life of the crane system using these hoists. Many of the cranes from the 1960’s and 1970’s have started showing their age. If fatigue cracks are discovered during inspections of the equipment, replacing the crane should be immediately considered. The same applies to the P Hoist itself. The hoist can show signs of fatigue failure in the frames and load bearing parts. The very age of P hoist equipment requires a contingency plan in the event that the hoist needs to be replaced.

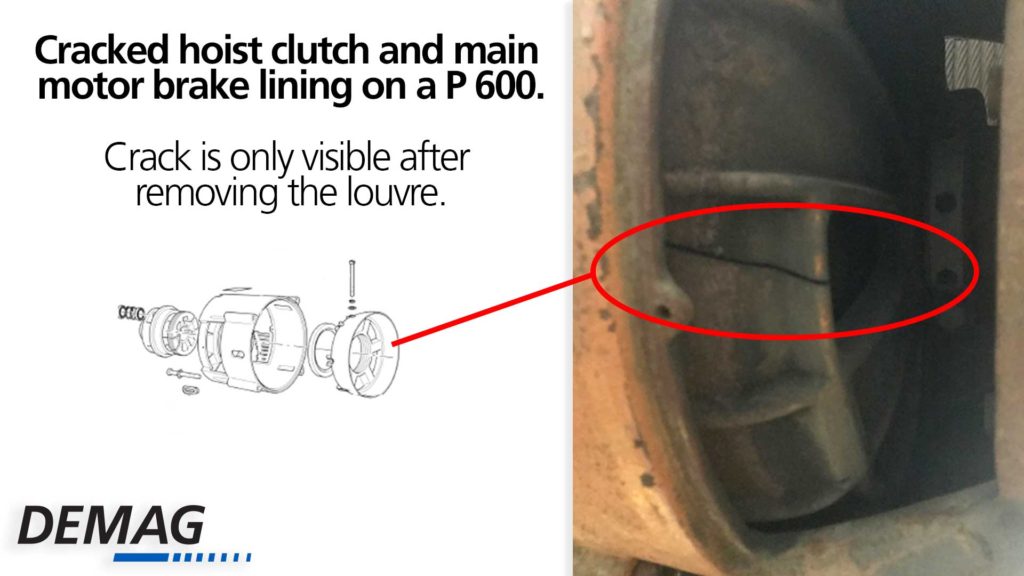

Common P Hoist failures that are reported to us are failures of components in the hoist. We often hear about the rotor loosening from the main motor shaft, collapsed dished washer packs and brake springs inside the motor, and cracked components in the microspeed clutch mechanisms. Any of these failures can result in lengthy and costly downtime while the problem is assessed and parts are placed on order. Due to the age of the P Hoist units, lead time and pricing for these spare parts have steadily increased while availability has decreased.

Other Factors to Consider

Regardless of the age of the lifting equipment in your facility, regular maintenance is critical. Overhead cranes and hoists should be inspected regularly and maintained on a proper schedule not just for optimal life, but for safety of the crane operator and people in the area around the crane. Maintaining wear parts in lifting equipment helps keep bigger issues at bay. Regular maintenance intervals are determined by the manufacturer. In every Demag component owner’s manual, we have included the regular maintenance intervals for our products. In addition to regular maintenance, tracking your total operating time is critical to determining your regular maintenance interval and can be a factor into choosing the proper lifting equipment for the job. Read more about the factors that affect the lifespan of your lifting equipment here.

Though the Demag P Hoist has been kept close to the hearts of many, the hoists found in North America are now 35-45 years old. As regular inspections find issues that need resolved, the cost of these spare parts continue to increase while the availability of the parts have decreased. If you are still using a P Hoist in your lifting operations, it is critical you continue with regular inspections and develop a contingency plan should a breakdown require lengthy downtime or the purchase of a new hoist. Please do not wait until it is too late. Give some thought as to what you will do in the event of a breakdown of a P hoist.

Learn more about the Demag DMR wire rope hoist for every day applications and for use in harsh environments.

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023

- Maintenance and Service Tips for Demag KB and ZB Motors in Non-Crane Applications - February 7, 2023