The Demag DH electric wire rope hoist was introduced to the market in 1985 at the Hanover Fair. Since then, the model has served customers with lifting needs up to 75 tons and in extreme environments. Like any equipment used in your shop, proper maintenance and inspection is necessary to keep you up and running to limit unnecessary downtime. One component on the DH wire rope hoist, and all wire rope hoists, that needs replaced periodically is the rope guide. We are going to take you through how a trained service technician would replace a broken or worn out rope guide and give you some tips on what prolongs the life of this component.

What does the rope guide do on a wire rope hoist?

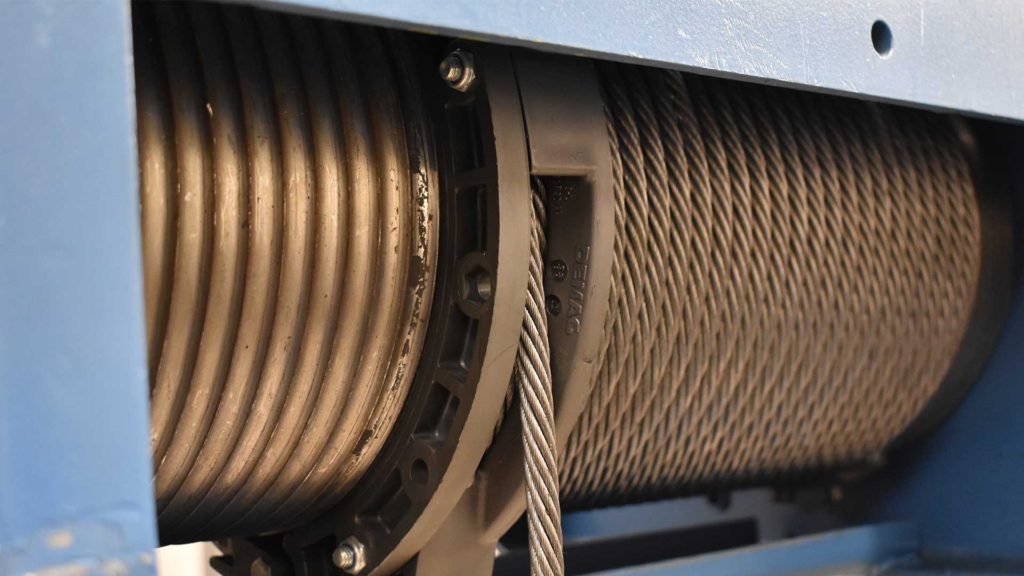

Rope guides on the Demag DH wire rope hoist prevent the formations of loops in the wire rope during operation.

The function of the rope guide is to prevent the formation of loops in the wire rope while operating the hoist. The easiest way to visualize this concept is with a failed cast on a fishing trip. Remember all those tangles in your fishing line after a cast that wasn’t smooth? The rope guide helps prevent that from happening. If a wire rope hoist were to form loops, it would be detrimental to the hoist unit itself. Trapped loops create slack in the wire rope so when the hook is lowered, the released slack results in shock-loading. Rolling over loops with consecutive wraps could result in a sheared rope and a dropped load because the overlap presses the underlying wire rope against the sharp-edged drum grooves. Both situations are dangerous to crane operators and your workforce in the area. Put safety first and remember to inspect your wire rope hoist at recommended intervals and properly train all personnel.

Why does the rope guide need replaced or adjusted?

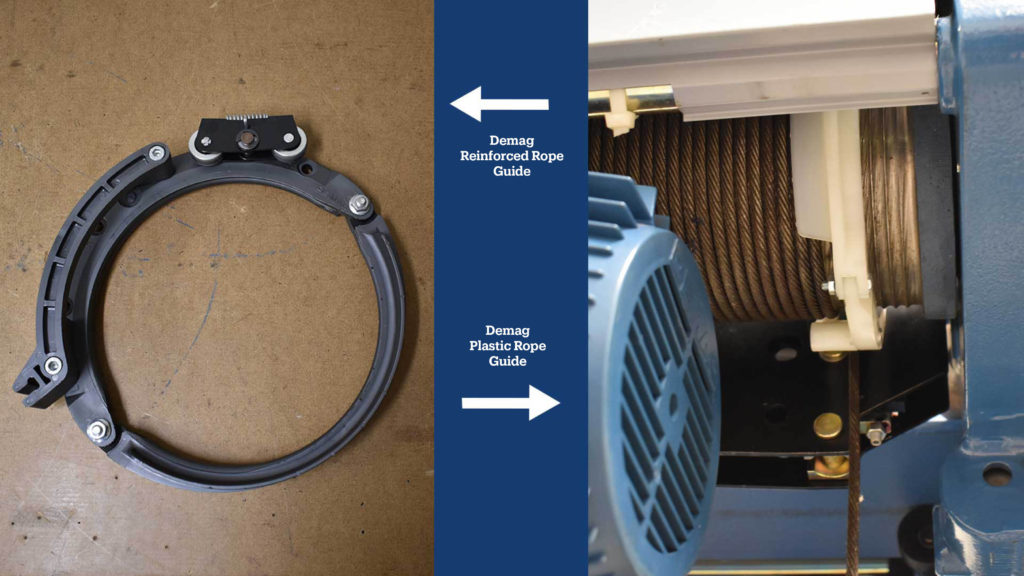

If issues like a cracked or wobbly rope guide are present, a trained technician can get your hoist back up and running safely.

Rope guides shipped with Demag DH hoists are made of poly-amide plastic. Modern rope guides are designed to include a double pressure roller assembly where rollers press directly on the rope so it smoothly tracks into the drum groove. This results in positive and consistent spooling. Demag wire rope hoists, including the DH and DMR models, have been designed so inspection, adjustment and replacement is easily accessible. Like any other wear part on equipment, as the rope guide plastic rides on the steel drum, the inside diameter (ID) wears over time. Once the operator or the inspector sees the rope guide wobble during operation, it’s time to replace or adjust it. Another issue your inspection may find is a cracked rope guide. A cracked rope guide can happen for a variety of reasons, but it’s frequently due to a load being side pulled.

What is the process to adjust or replace a rope guide on the DH wire rope hoist?

For a trained technician, making an adjustment or replacing the rope guide can be done with just a few tools.

The anatomy of a rope guide is simple. It has two major segments that overlap where they join. It has slotted holes for simple nut and bolt connections. Sometimes when you see a rope guide wobbling during use, adjusting it can fix the issue. Unfortunately, there is only so much adjustment that can be made until replacement is necessary. For a trained technician, adjusting the rope guide is simple. They loosen the bolts, bring the two halves closer together and retighten the bolts so the guide can still move freely without binding on the outside diameter of the drum.

As always, adjustment or replacement of a wire rope guide should always be done by a qualified technician. Whether adjusting or replacing, the first step is to release the pressure exerted by the rollers. This is accomplished by prying up on one half of the roller assembly to align a series of holes across the two halves of the assembly for straight-on insertion of a pin or similar object. This pin holds back the rollers from exerting pressure and the guide can be removed. When you are installing a new rope guide, a pin is already inserted in this hole. Whether you are adjusting or replacing it, remember to remove the pin when finished with installation on the drum so the rollers can exert the pressure needed to do their job.

How can I extend the life of a rope guide?

If cracked rope guides are a common problem, Demag offers an reinforced rope guide.

There are many factors that determine the life of a rope guide. Since the part is made of plastic, they are more vulnerable to the effects of a side pull. This brings the steel wire rope in contact with the plastic guide, which can cause the guide to crack or inflict other damage. Side pulling while lifting a load should be avoided. Always make sure your crane operators have proper training. Another tip to extend life is regarding the torque arm. The torque arm rides on a portion of the hoist frame. Keeping this area as clean as possible will prevent binding and subsequent breakage of the torque arm. If you do follow these two suggestions, but still find that you’re replacing the rope guide often, Demag offers reinforced rope guides made from a combination of plastic parts with metal reinforcements. Contact your authorized Demag dealer to order.

The rope guide is an important part on your DH wire rope hoist. It assures the wire rope is spooled properly on the drum so you can lift loads safely. Keeping spare parts on hand can help you minimize downtime and be prepared to get the job done. Remember proper inspection and maintenance are key to catching issues early. Always call in a qualified technician for the job because safety is always your #1 priority.

Demag has network of authorized dealer partners across the US and Canada to help you maintain your equipment or be there to support you when you need to order parts or components. Contact us today!

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- From Customer to Demag USA Technical Trainer - May 9, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023