Overhead lifting can be configured in a multitude of ways to meet your unique process needs. Freestanding workstation cranes are an overhead lifting solution that adds lifting capabilities nearly anywhere within your production facility. A freestanding configuration can help your workforce lift and handle loads up to 2 tons and optimize your operations.

Freestanding workstation cranes consist of a support structure, enclosed rail workstation crane with runway and bridges, and lifting devices to meet the needs of your processes. Common lifting devices used on these workstation cranes include chain hoists, electric balancers, and air balancers. These devices make lifting and maneuvering loads more ergonomic for your workforce while making a process more efficient.

Improved Ergonomics by Eliminating Manual Lifting

Adding lifting equipment to your operations can bring a wide range of benefits. A freestanding workstation crane and chain hoist can eliminate manual lifting processes. OSHA and industry resources like the Ergonomic Assist Systems & Equipment group from MHI provide facts and resources to help you improve the safety of your lifting processes. Freestanding workstation cranes can help make loading a component into a machine safer when a lifting device is added.

Optimize an Existing Process or Repurpose an Area

Freestanding workstation cranes can optimize an existing process in your operations or repurpose an area for a different process. Improving a process makes your operations more efficient and improves safety for your workforce. By allowing free access to the area under the crane, machinery, tools, and your workforce can have uninterrupted access. A cantilever configuration eliminates the support structure on one side of the crane system for full access.

When you need to repurpose an area of your production, adding a workstation crane adds flexibility to a space. Adding a lifting device allows your workforce to handle awkward and heavy loads, as well as lighter loads. You get safer handling for lighter loads and new capability to lift heavier loads. Freestanding workstation cranes can easily be added nearly anywhere within your facility.

Add Lifting Capabilities Between Your Existing Manufacturing Cells and Machines

Moving existing machinery in your manufacturing areas is a big project. Freestanding workstation cranes can be added to fit within and between existing equipment. This can eliminate the need to physically move machinery while adding lifting capabilities for your operators. A lamp post style freestanding workstation crane allows for offset column locations to support the crane system around existing equipment.

Add a Dedicated Assembly or Process Area

Since it can be added anywhere your facility floorspace will allow, a freestanding workstation crane system allows you to add a dedicated assembly or process area that allows lifting, floating, and handling of loads. Depending on your process needs, the enclosed rail crane suspended from the columns can be customized to meet your goals. It can be as simple as a runway with one bridge or as complex as a system that includes turntables or track switches. This dedicated area is customized to your exacting needs.

Systems That Grow with Your Future Operations

Because a Demag freestanding workstation crane uses a KBK modular crane system, the system will grow with your future needs. One unique benefit of a freestanding workstation crane is that it can be moved to a new location later when your processes change. Since the columns are attached to your facility concrete, the entire system can be moved when your processes change.

Demag KBK systems are designed to be customized to your needs. With the widest offering of standard, off-the-shelf products and accessories, KBK can easily and efficiently be customized to meet your unique needs. These accessories cover complex material handling components like turn tables and automation products or simply a runway with one bridge.

Growing with your future process needs can include connecting your KBK ceiling mounted and freestanding workstation crane systems. All KBK enclosed rail types can be connected together and added to for your future process needs. Read more about how Demag KBK can grow with your operations.

Freestanding Configurations to Meet Your Needs

The Patented Freestanding Cantilever Workstation Crane from Demag

Our exclusive Cantilever Workstation Crane gives unblocked access to machinery, tools and personnel with one completely open side. The support structure is installed on one side with the supporting cantilever overhang suspending the KBK crane. We have installed this freestanding crane system configuration in assembly operations to improve the safety of personnel. With one completely open side, the area under the crane is easier to clear clutter and unneeded items during different stages of the assembly process. Use the Cantilever Freestanding Workstation Crane for applications up to 1,100 pounds.

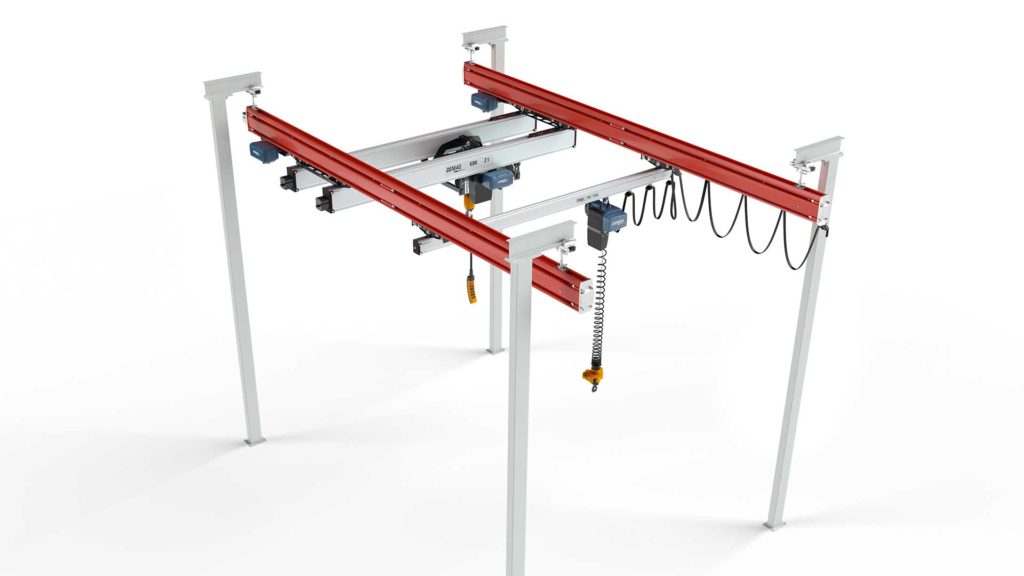

Lamp Post Freestanding Workstation Crane

A Demag Lamp Post Workstation Crane can be inserted within your existing production area. Since there is no header and column locations can be offset, this configuration can be added to around machinery and other equipment while adding ergonomic lifting capabilities in an area. Add ergonomic, safe lifting for capacities up to 2 tons with the lamp post freestanding workstation crane configuration.

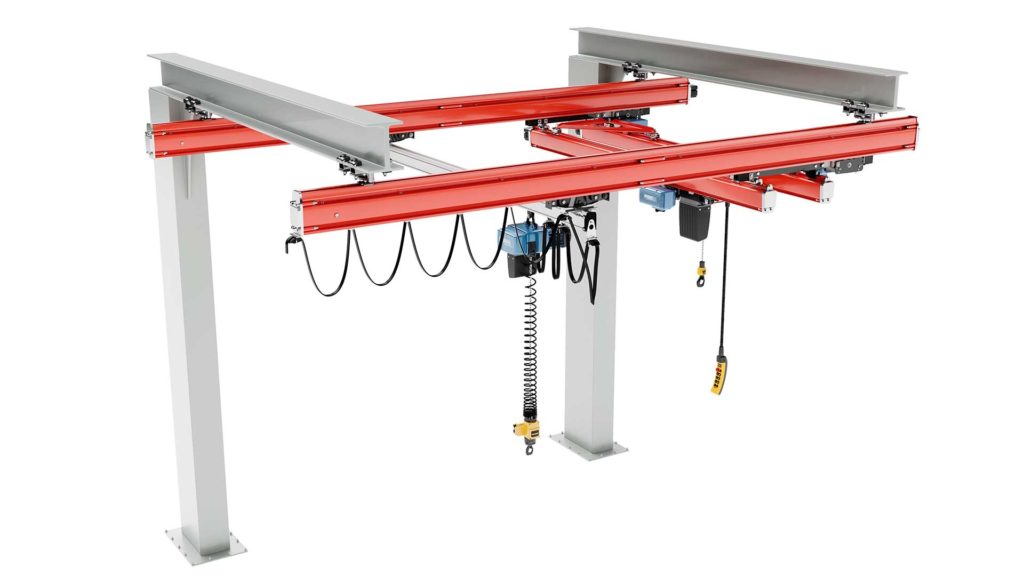

Standard Portal Freestanding Workstation Crane

Standard Portal Freestanding Workstation Cranes by Demag allow you to add standalone lifting nearly anywhere in your production facility. This configuration requires column locations to be equal to the system’s capacity needs, meaning it may not fit between your existing machinery footprint. The benefit of the standard portal workstation crane is in capacity and bridge lengths. This configuration accommodates a longer bridge lengths and column spacing than the other configurations. It allows you to exactly customize the needed workspace in your facility. Use a Standard Portal Freestanding Workstation Crane for capacities up to 2 Tons.

Freestanding workstation cranes are flexible to meet your lifting needs. Whether you need to add lifting capabilities to an area with unused floor space or within the machines in your manufacturing cells, there is a configuration to meet your needs. Demag workstation cranes are flexible with the widest offering of standard, off-the-shelf accessories to customize it to your exacting needs. Because our workstation cranes are built with KBK enclosed rail, you’ll have the freedom to grow with your future production needs. Read more about Demag Freestanding Workstation Cranes on our website.

Still deciding on the option that will optimize your operations? Read our post here: Jib Cranes: Adding Lifting Capabilities Nearly Anywhere in Your Production Facility.