Electric trolleys allow operators to move heavy, awkward loads ergonomically and efficiently. Using a pendant or radio, the trolley moves on the monorail or bridge to the next step in the manufacturing process.

Electric trolleys, or e-trolleys, eliminate manual movement of the load. Components of the trolley include a housing for the control system and electrical components, gear motor or travel drive, encoder, and connections to attach the unit to the lifting device and trolley system. Attached to the trolley is a lifting device like a chain hoist. The Demag E22C electric travel drive was specifically developed for use with the full line of DC Chain Hoists.

Demag E22C electric travel drives are designed with the same plug and lift philosophy as DC chain hoists. Electrical connections are easy for installation, including plugging in the DC chain hoist. Once installed and inspected, your customer will notice smooth starting and braking characteristics, minimizing load sway.

While the default parameters for the E22C travel drive may provide optimal performance for most applications, technicians can perform additional programming to meet unique application requirements. Tailor the maximum speed, acceleration and deceleration to meet different travel requirements. Programming can be accomplished through the pendant, using the keypad terminal, or with a PC and Demag SoftTerm software.

Programming the Demag E22C Trolley with the Pendant or Demag DRC-DC Radio Control

Easily program maximum speed, acceleration and deceleration using the Demag pendant or radio control. To get to the listing of parameters, you will follow the process shown in the Assembly Instructions for the E22C Drive (document #214 810 44 depending on your language requirements). Once in programming mode, you will have access to the parameters using the pendant or radio pushbuttons to tailor the drive to meet your customer’s requirements. Note, if you are using a non-Demag pendant or radio, you must program the E22C with a PC and SoftTerm software or keypad terminal.

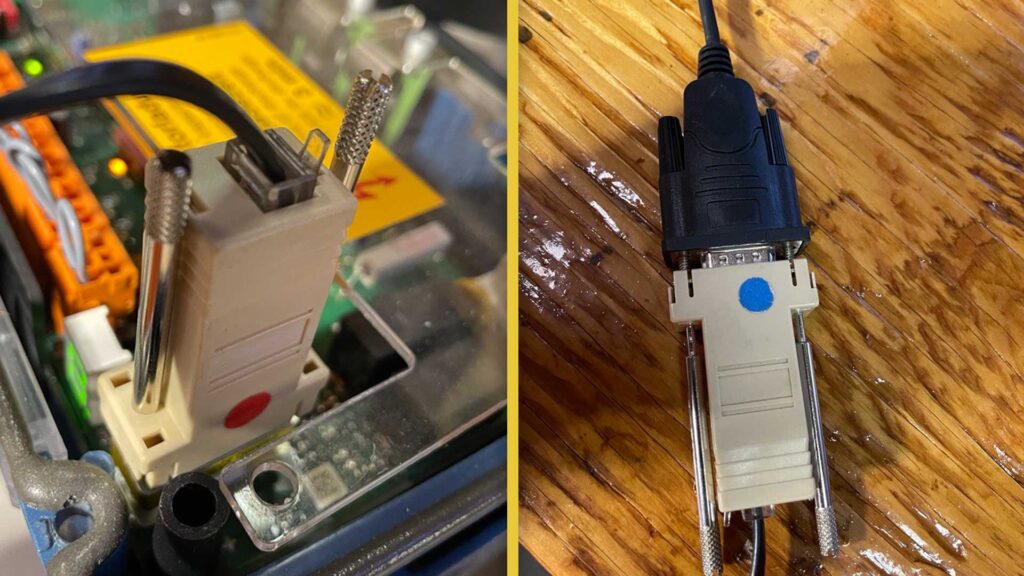

Programming the Demag E22C Trolley with Keypad Terminal

Setting parameters with the keypad terminal requires the keypad terminal, part # 537 414 84. This keypad is connected to the drive on the X14 plug, giving you a visual view of the parameters and settings. Change the parameters with the buttons on the keypad, following the directions in the installation document.

Programming the Demag E22C Trolley with PC and Demag SoftTerm Software

Using a PC plus the Demag SoftTerm software is an electronic version of the keypad terminal. Once the drive and PC are connected, the SoftTerm software will initiate and you can change parameters on screen. If you are using a non-Demag pendant or radio, you will need to use the SoftTerm software or keypad terminal to make parameter changes.

The Demag E22C travel drive is designed to be easily tailored to the application requirements. With three ways to program parameters, technicians can efficiently make the changes to the speed, acceleration, and deceleration needed to optimize the drive for the customer.

Don’t forget to read our post on the Set Up Differences Between the Demag E22 and E22C Travel Drives before your next service call.

Searching for an electronic travel drive option for your DC chain hoist? Reach out to us for a quote.

If you are located outside of the US or Canada and you need support, use our Global Contact locator to find the Demag office nearest you.

- Precise Control & Digital Interface | Demag DMI Inverters - May 7, 2024

- Demag DRC-DC Radio Control System: Efficient Transmitter Replacement - March 26, 2024

- Navigate Model-Specific Codes | Modern Demag Light Lifting Products - November 21, 2023