Moving a heavy load isn’t just for an overhead crane. When you look around the material handling industry, you see overhead cranes and other types of material handling, such as vertical and horizontal material handling solutions, used in industrial manufacturing environments and terminal ports found worldwide.

As an overhead crane dealer and manufacturer of material handling solutions, we are here to remind you to look up and down to find opportunities. Learn more about both our vertical material handling and horizontal material handling solutions today.

Overhead Lifting

Nearly every industry uses an overhead crane of some sort to help lift and move materials during the manufacturing process. Overhead cranes encompass lighter loads with enclosed rail crane systems and the heaviest loads with a double girder crane and wire rope hoist or winch. Overhead lifting can make your operations safer and more efficient, no matter if you use an enclosed rail crane or monorail like Demag KBK or an overhead traveling crane with a Demag DVR or DH wire rope hoist.

Horizontal Material Handling and Movement of Heavy Loads in the Industrial Space

Precise horizontal material handling and movement in the industrial space is vital to production efficiency. The application of material flow tools is vast in these industries. Metals processing, production, and storage may use a transfer car to move raw materials from place to place within the facility. Manufacturers of automobiles or large equipment may use transfer cars to transport partial or fully assembled components throughout the production facility or production lines.

Many manufacturers require chemicals, paints, or solutions to be combined at some point in the process. Tippers and fillers can assist manufacturers in these industries. These tippers allow for chemicals and solutions to be safely combined, sometimes reducing or eliminating the need for your workforce to be exposed. The AC induction motor and wheel solutions need to withstand the environmental requirements of each unique application. In addition, the tipping process may need to be very precise from stopping at a specific location to tipping so the liquid is combined at a specific rate.

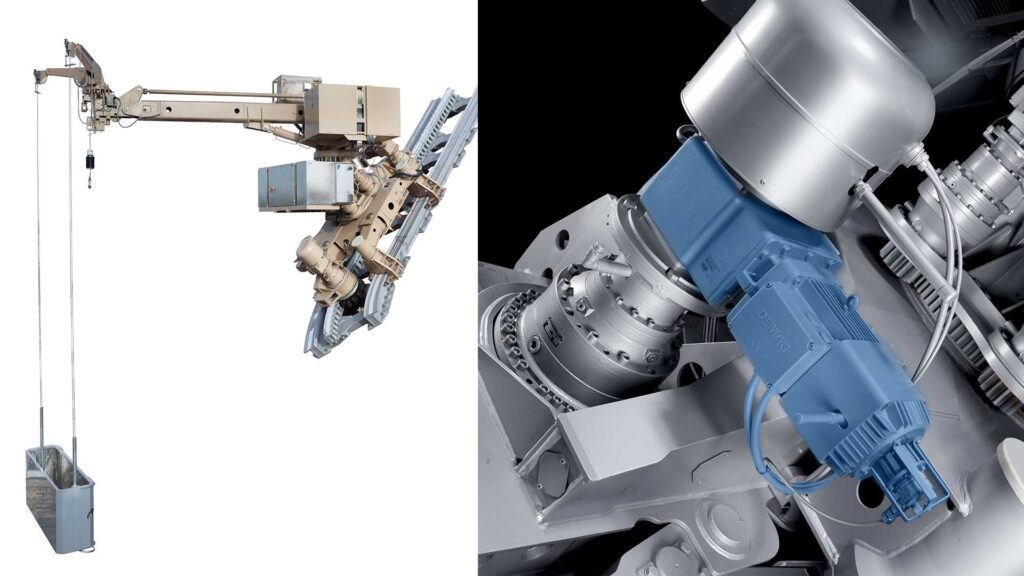

Manufacturers and horizontal material handling dealers who fabricate solutions that move heavy loads side to side with precision need components that are reliable, efficient, and optimized for these applications. Demag’s drive solutions include gearmotors that meet a variety of requirements. From the very precise and extreme environmental needs to more of a general industrial environment, there is an AC induction motor to meet your needs.

Demag wheel system solutions are pre-engineered, full-wheel solutions that include the wheel, bearings, and housing. Each wheel used in a Demag wheel system can handle a capacity up to 88,000 lb.

Vertical Material Handling Without an Overhead Crane

In industries with large die handling, retrieval operations, or automated storage, stacker cranes may be a vertical material handling solution used to grab and replace large items. The system is shaped like a mast that can move up and down to use forks or grippers to grab an item for transportation. Stacker cranes need a power, wheel, and control system to deliver the goods.

No matter how precise your requirements are for a stacker crane application, Demag gear motors can deliver the goods. For the most precise applications, the Demag FG Microspeed motor combination pairs two conical rotor motors to give you the widest range of speeds from fast to very slow. Paired with the wheel block system to meet the application capacity needs, you can design the entire system with Demag, including the controls and power delivery.

Lifting and Moving the Heaviest Loads from Ships in Terminal Ports

From the lived experience of the COVID-19 pandemic, nearly everyone understands how integral the worldwide terminal ports system is to our economies. Various types of equipment are used in these ports for dry bulk handling and container transport. The products used for loading and unloading ships and then transporting those goods to where they need to go need to be efficient, reliable, and robust.

As manufacturers of port loaders and unloaders for bulk handling and containers, you are looking for components to power and move the machines you’re building. Engineers creating the solution for each application want moving components to offer long, reliable life and efficient operation. AC induction motors, gear motors, and wheel sets are common components of these machines.

There are many ways to move heavy loads in your facility. These horizontal and vertical material handling solutions will be developed by an expert dealer or manufacturer and use powered components like gear motors and unidirectional wheels.

The combination of 3 items – the AC induction motor, gearbox, and wheels – work together to move at an efficient speed, at the right location, and stop at the exact right time. This combination of factors can optimize your operations. Whether you’re an overhead crane dealer or manufacturer of other material handling solutions, remember to look up and down for opportunities.

Contact Demag for Your Horizontal and Vertical Material Handling Solutions

To learn more about both horizontal material handling and vertical material handling solutions and how they can accommodate your operation’s needs, please reach out to us. We look forward to helping answer any questions you may have.