Automation of repetitive lifting processes can bring benefits in tight labor markets and make your operations safer for your workforce. It can also optimize material flow through your facility enhancing throughput. In today’s labor market, it can be challenging to hire so you may be looking for alternative options to keep your operations running. If you’re looking at automating a lifting process in your facility, read on to learn more.

Types of Lifting Automation

An automation process using an overhead crane or monorail could include grabbing or securing a part, lifting, horizontal travel, lowering, and release or placement of the part. A process can be fully automated without any operator assistance or semi-automated with portions of the operation performed by an operator. An automated process can complete repetitive tasks, allowing an operator to complete other, more valuable tasks.

Semi-Automated vs Fully Automated Lifting

As you are exploring adding automation to your production processes, you should understand differences in semi-automated or fully automated. Both types of automation can complement your unique needs in different ways.

Semi automation is a process that has an automated component but requires some operator interface, normally to begin or end the process. A simple automation example could be an operator connecting a part to the hook or end effector. Then, once certain criteria have been met and confirmed by the control system, the automation process is enabled and uses horizonal travel to an unloading area. An automated portion of the process can save time and resources since the operator does not have to accompany the part during transport.

Fully automated processes potentially run without operator intervention, allowing manpower to be saved or redeployed as needed. Using the same example, full automation could be achieved by using an automated gripper or end effector to secure and release the part at the beginning or end of the process. There are additional costs for full automation, like the required grippers and additional electronic control systems, so these systems can cost significantly more than semi-automated systems.

Start By Looking at How Your Process Looks with Automation

Determining the sequence of operation is the first step in a lifting automation project. Similar to a story, it details how the process moves from beginning to end. For example, a simple sequence could be lower 3 feet, pick up a component from the pallet, lift 4 feet, travel 20 feet, stop above the centerline of the conveyor, lower 1 foot and release the part, then return to the starting position. Always consider the required timing of each operation and what may be required in the future.

From here, add detail to your story or your sequence. If operators will be involved, determine which steps they will control. Look at how operators will interface with the equipment, perhaps with buttons or a control screen. This allows them to select where to send or receive the product being transported.

Other specifications you’ll evaluate are the speed and accuracy needed for the operation. There can be considerable costs when high accuracy and speed are required. In addition, any external signals from offboard equipment like conveyors should be detailed in the initial sequence of the lifting automation operation. The more accurate and complete information you gather, the better and more accurate your quote will be.

Key Components of the Lifting Automation System

Automation of a lifting process involves many components. The automation control system is all the sensors and other components that work together to create your process. An electric chain hoist is an excellent choice for the lifting axis up to 5 tons. For heavier loads, electric wire rope hoists can be used.

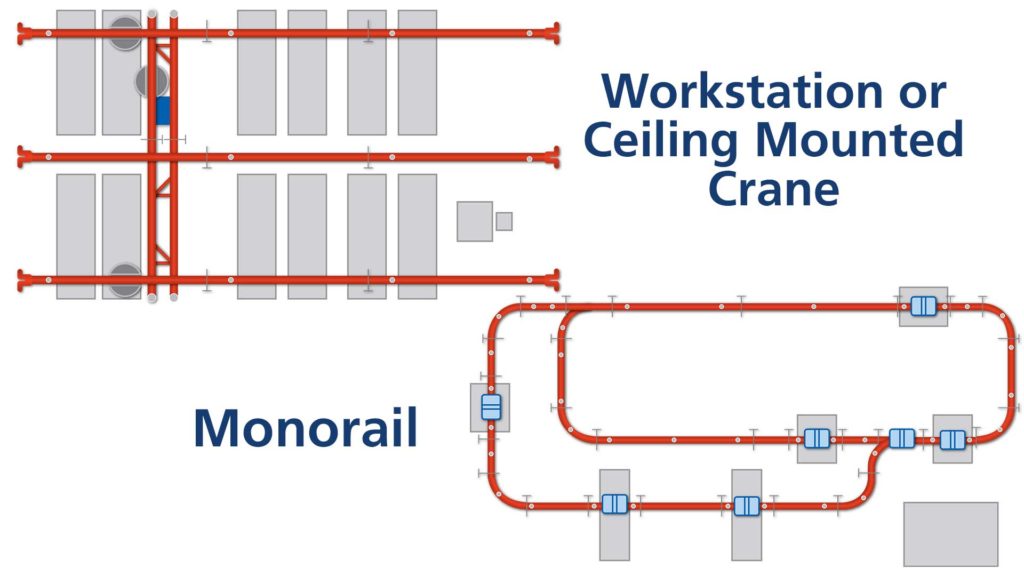

Horizontal travel can be achieved with a freestanding workstation or ceiling mounted crane if a variety of pick and place locations are required in a rectangular area. Locations in a linear path, whether straight or curved, can be serviced using a monorail system. Electric tractor motors provide the powered movement for horizontal travel. The automation control system includes all sensors, communication, motion control, PLCs and other components that work together to control the automated process.

Automation can be implemented on monorail and enclosed rail crane systems. Chain hoists can be outfitted with variable speed lifting/ lowering, geared limit switches, encoders, and load measurement devices. For horizontal travel, monorails and runways can be outfitted with variable speed tractor drives, encoders, and travel limit switches. Use onboard control system signals (PLC system) to connect in offline equipment to your automation, wired or wirelessly.

Implementing Safety

An automated process typically begins with both a visual and audible warning letting the operator and others know the process has begun. Areas with automation are always protected from entry by personnel with fences, gates, or sensors to prevent entry or to stop the process if anyone enters. If loads must be transported above personnel, a screen can be installed under the crane or monorail for full protection of those under the path. The automation controls can be tied into other plant equipment to ensure that an automated process is always safely completed. In addition, eliminating repetitive tasks from operators can keep your workforce safer.

Choosing a Manufacturer and Dealer Partner

Investment in automating lifting processes is an important decision that needs to be supported by knowledgeable, expert partners. The manufacturer chosen should have a wide range of product options. This allows you to tailor the project to meet your exacting needs with standard offerings. A manufacturer with a wide product offering will assure the automation implemented will work seamlessly.

Demag light lifting solutions can help automate lifting processes up to 2 tons with KBK light crane systems and monorail and DC electric chain hoists offer the widest range of options in the industry. A KBK Crane or monorail system can include automated branching components such as curves, track switches, turntables, and interlocks. Demag KBK Crane and Monorail systems also have an internal busbar system for reliable power delivery throughout any system. The possibilities with this modular system are practically endless

Demag chain hoists are available in off-the-shelf configurations including single hoists, dual chain hoist system for synchronous two-point pick up, and quad lead off for synchronous 4-point lifting. Available in 2-speed or variable speed, they can be fitted with a variety of precise positioning switches and encoders.

Design, installation, maintenance, and troubleshooting of your automation system requires a knowledgeable partner. Demag’s network of expert dealers in your area will partner with you to create and install a solution to meet your unique needs. Ongoing maintenance and troubleshooting are important details to consider. Partnering with one of our expert dealers will assure you will receive the support you need.

Adding automated lifting processes to your operations can enhance material flow and allow your workforce to complete value-added tasks. Whether you need fully automated lifting or semi-automated lifting in your facility, make sure you evaluate your processes and understand your needs. Then, make sure you work with an expert dealer and lifting products manufacturer to tailor the system to your unique needs.

Need to talk to an expert? Reach out to us using the form at the top of this blog post.