Wire rope is a machine! It is the workhorse that lifts the heavy loads on wire rope hoists. As a crane technician, there is an endless amount of information you should know about wire rope. The more you understand, the better resource you can be to your customers. Luckily, you don’t need to be the expert! There are others to help you out, including crane and hoist manufacturers, wire rope manufacturers, and other crane technicians.

In this article, we will talk about how Demag designs wire rope hoists and selects the wire rope for models that you can buy today, along with the wire ropes you will find in the field for inspections and repair.

Lay of Wire Rope Definitions

Direction of Lay

In the world of wire rope, lay has many meanings and definitions. First, we will go through the directional meanings. Lay can refer to the direction in which the strands are twisted around the core of the wire rope. When left-hand and right-hand lay is referred to like this, it is describing whether the strands are twisted clockwise (left hand) or counterclockwise (right hand) around the core.

For a frame of reference, grab the wire rope in either hand with your thumb pointing up. When the strand appears as if going up to the left, this is a left-hand lay rope. When it appears as though it is going up to the right, this is a right-hand lay.

Lay can also refer to the cut of the groove corkscrew in the drum and the corkscrew can go to the left or right. The wire rope will start gathering on the left-hand side of the drum in the case of a left lay and the opposite for right lay. One way to determine this is to look at the drum from the end where the rope is clamped. The term lay can be used to describe the distance of a complete wrap of a strand once around the core.

When conducting a wire rope inspection, knowing how to measure the lay is critical. It is measured by determining the distance starting on the outside wrapping the strand one complete time back to the same outside position. This measurement is used to determine the maximum number of broken wires allowed within a single lay and for the number of broken wires in the same strand in a lay. Always consult your inspection criteria bodies, like CMAA and HMI, for the most up-to-date standards.

Regular vs. Lang Lay

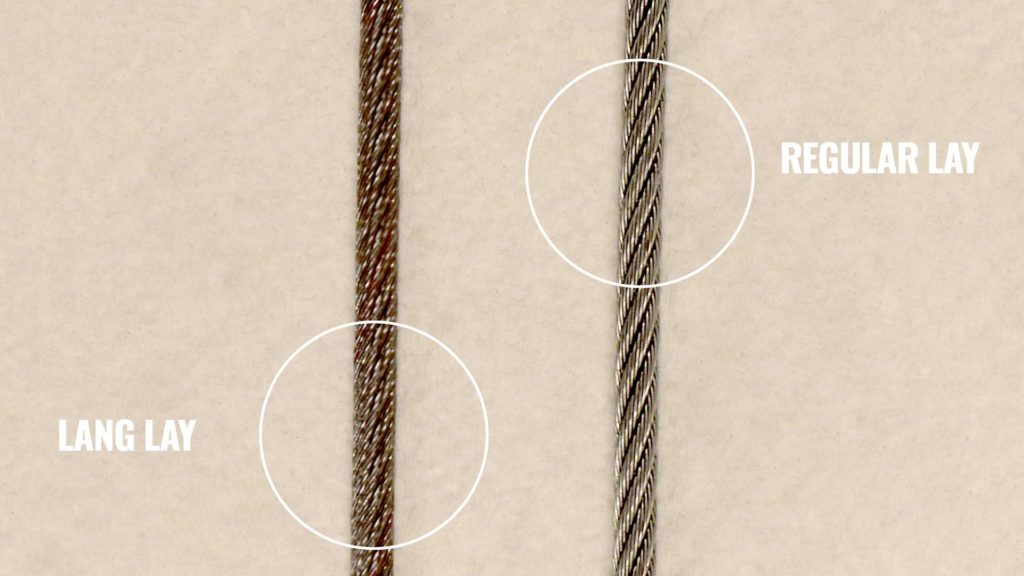

Lay can also denote whether a rope is a regular lay or lang lay. Regular lay and lang lay rope are different types of wire rope and differ based on the wire orientation in the strand. Regular lay rope wire appears as though the outermost wire surface is aligned parallel with the centerline of the wire rope axis. Lang lay rope wires appears to be at a 45-degree angle with the wire rope centerline axis.

Lang lay type of rope allows for more surface contact with the groove surface on the drum or sheave, increasing the support zone and decreasing the load by spreading it out over a larger area. It is more costly to manufacture, but it can be used in special cases where better wear life for the drum and sheaves is needed. Today, regular lay rope is commonly used unless there is a specific design need to use lang lay wire rope.

Right-Hand Lay vs. Left-Hand Lay of Wire Rope and Drums

Countries and industries may have different standards or best practices when using different orientations for the lay of wire ropes, specifically right-hand lay vs. left-hand lay. Due to the direction the strands are twisted (clockwise or counterclockwise) each lay rope has its own advantages depending on the function it’s being used for.

Right-hand lay is more commonly used than left-hand lay, and its coiled ropes tend to roll more smoothly when it comes to pulling a load. Right-hand lay ropes also resist any kind of tangling between them. Applications with right-hand lay ropes include:

- General hoisting lines

- Bell ropes

- Tow ropes

- Logging operation lines

- Lifting harnesses

- Crane hoisting ropes

Left-hand lay rope is known for withstanding spinning and is normally used for specific safety applications because it has a better grip and counteracts any kind of twisting. Left-hand lay ropes are used for applications such as:

- Lines for mooring ships

- Anchor lines for buoys

- Wires suspending bridges

- Mountain climbing

- Sailing

In the USA, the wire rope industry recommends using a right-hand (RH) lay rope on a left-hand (LH) drum corkscrew and a left-hand (LH) lay rope on a right-hand (RH) drum corkscrew. This is recommended for good spooling of the rope, especially on a grooveless drum. In most cases, Demag designs our wire rope hoists counter to this best practice, but for a major engineering reason that benefits the user and for additional safety.

Demag wire rope hoists are designed for RH rope on a RH drum and LH rope on a LH drum. This design creates straighter drops of wire rope down to the bottom block as using the same strand lay and corkscrew twists the strands tighter around the core. The straighter drop eliminates interference in a 4/1 reeving configuration as the rope crisscrosses during lifting. This becomes very apparent when the lift height is around the 70-foot range.

To make sure that the hoist has positive spooling, the drum is designed with a partial groove and is equipped with a rope guide with pressure rollers or a ring that keeps the rope in the groove.

When it comes to hoists configured for 4/2 reeving with 2 attachment points for the same rope, only one side of the drum follows the best practice. Since there are 2 attachment points in 4/2 reeving, one drum corkscrew is RH and the other LH. Inherent from the reeving design, close to vertical lifting is achieved and crisscrossing interference is not a concern.

Changing the Wire Rope on a Hoist

Due to wear on the drum and sheaves, we will never recommend changing the lay of the rope used on a hoist when the wire rope needs changed. The existing wire rope lay has already established wear patterns on the drum and sheave that could make changing the rope with a different lay dangerous. Being able to identify or find out what type of rope is used on a wire rope hoist is key to success when wire rope needs changed.

Wire rope is a complex form of equipment, lifting the heaviest loads like space shuttles and precast concrete components. It does the heavy lifting when a load is being lifted by a crane and wire rope hoist. Having a good understanding of wire rope is essential for all crane technicians.

Being able to understand what lay means and how to determine what kind of rope is on an existing hoist is just the beginning. Not only will this knowledge allow you to be a more effective technician for your customers, but you can promote safety in the industry.

Contact Demag for Questions About the Lay of Wire Rope and More

If you have any questions about the various kinds of wire rope, Demag has a team of industry experts ready to help, so contact us today.

- Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Inspection - December 21, 2023

- Diagnosing Additional Error Codes on Demag CANBUS Hoists and Cranes - March 28, 2023

- Maintenance and Service Tips for Demag KB and ZB Motors in Non-Crane Applications - February 7, 2023