Jib Cranes at a Glance

- Versatility and Space Efficiency: Jib cranes can be installed almost anywhere in a production facility to enhance lifting capabilities, making underutilized areas productive. They are available in freestanding or wall-mounted configurations to suit different space requirements.

- Complementary Lifting Solution: They complement existing overhead crane systems by adding lifting capabilities within the reach of the jib’s boom, thereby increasing the efficiency of production processes.

- Range of Applications: Jib cranes are suitable for various manufacturing and assembly operations, outfitted with devices like electric chain hoists and air balancers to meet specific process needs.

- Safety and Productivity: By automating lifting processes, jib cranes help improve safety and reduce the risk of workplace injuries, contributing to a safer and more productive environment.

- Customization for Operational Needs: Jib cranes can handle loads up to 2 tons with standard designs, and more robust options are available for heavier capacities, along with features like powered rotation for frequent use.

There are many options for lifting equipment to help operators do their job safer and more efficient. Commonly seen in many different industries and operations, jib cranes are a flexible lifting option. Jib cranes can make an underused area of your facility into a productive work cell or compliment an existing overhead crane. These cranes can provide lifting and handling capabilities within a machine area, assembly station, or in loading and unloading areas. In this post, we’re talking about jib cranes, the different configurations available, and how they are used in many different operations.

What Is a Jib Crane?

A jib crane is an overhead crane that adds lifting and handling capabilities nearly anywhere in your production facility. It is unique because it can complement new or existing production areas unlike a traditional overhead bridge crane, monorail or enclosed rail crane.

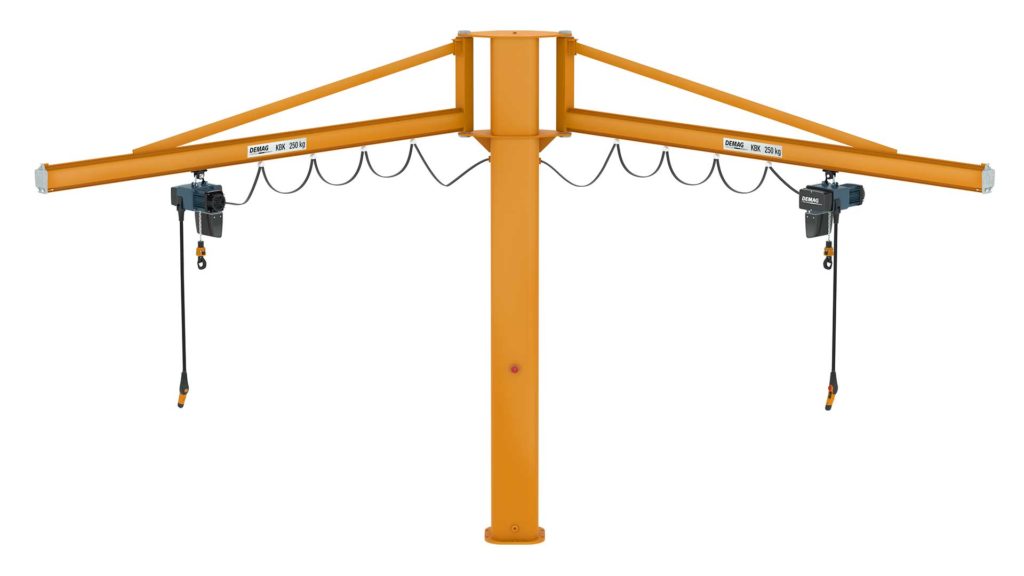

The most recognizable feature of a jib crane is the rotating boom that protrudes off the wall mount or pillar. The boom can be mounted to a suitable wall or building column, or a pillar can be mounted to the floor. Allowing for both rotation and linear movement, the boom allows operators to use lifting devices. Operators can quickly and efficiently lift and move components in the area covered by the rotating jib. A wide variety of liftin devices can be used on the jib boom like electric chain hoists, electric balancers, and air balancers. Certain jib cranes can also have 2 booms fitted for neighboring workspaces.

Jib Crane Types: What Are the Different Kinds of Jib Cranes?

Freestanding Pillar Jib Crane

A freestanding pillar jib crane is attached to the existing reinforced concrete floor of your production facility. This type of jib crane is designed to be installed almost anywhere in your facility. Pillars come in a variety of heights to clear obstructions and provide the necessary lift height for your installation.

The hoist and trolley travel along the boom with the ability to rotate the boom up to 360°. When a freestanding pillar jib crane rotates, the operator can lift a load and then rotate the boom to the area needed for the next step of the process. Jib cranes can help you replace manual lifting processes in your facility.

When you are considering a freestanding jib, you will work with your jib supplier to determine the construction, thickness, and quality of your existing concrete floor. Then taking your needed capacity into consideration, any necessary changes to your building, like if it is necessary to pour a concrete foundation for your jib crane, will be determined at that time.

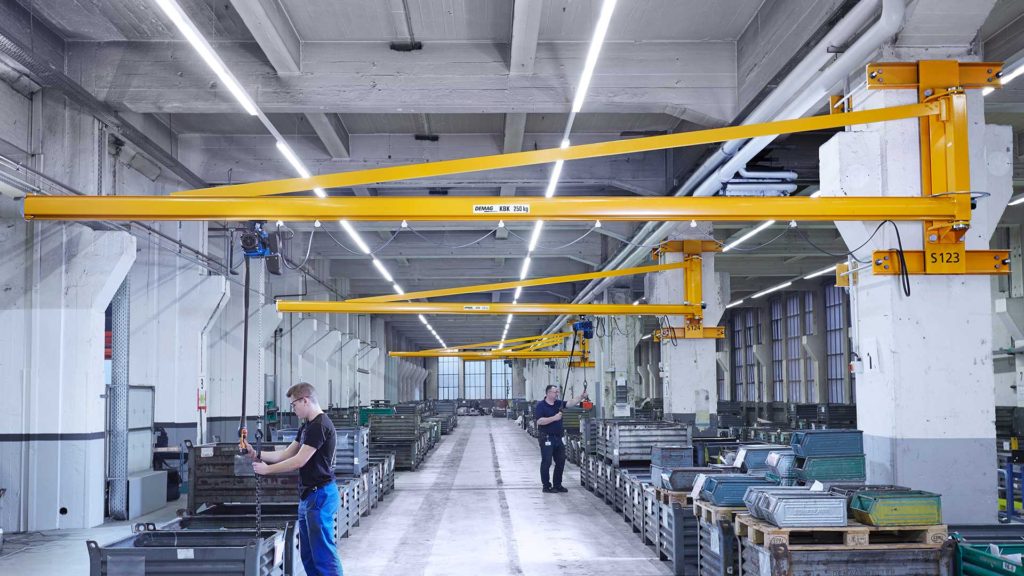

Wall-Mounted Jib Crane

Jib cranes can be attached to the wall of your building in a wall-mounted jib crane design. If your operations have little floor space, this jib crane configuration could be the right option for you. Because these are attached to the wall or a pillar of your building, they do not take up floor space like a freestanding pillar jib crane. Wall mounted jib cranes allow for 180° – 270° degree rotation.

Another aspect to consider is the location of your building’s pillar. If you plan to add a jib crane to a building pillar, it is possible the pillar may not be in the correct placement to coincide with your production process. A wall mounted jib crane requires a wall or pillar of your building to meet exacting specifications. You will work with your jib supplier to check the structural strength of the wall or building column and determine the mounting hardware used.

Jib Cranes for Heavier Capacities

As capacities get heavier, the design of a jib crane changes in different ways and foundational requirements grow. Jib cranes are typically used in applications up to 2 Tons, but larger capacities of 5 Tons or more are possible.

Manual or Powered Rotation

Rotation of a jib crane can be manual or powered. Lighter capacity applications can easily be rotated by hand. Heavier applications, such as 2 Tons and higher, can be equipped with powered rotation for frequent use. Additional options for rotating jibs include adjustable rotation stops. These limit the rotation of the boom to avoid collisions with surrounding equipment.

Rotating a jib crane is easier when the load is closer to the end of the boom and more difficult when the load is closer to the pillar or wall mount end of the boom. If the jib crane you need will be rotated manually, rotation with the load close to the pillar or wall mount end of the boom should be avoided. It is best to operate most frequently in the outer two thirds or less of the jib boom length for manual rotation operations.

Why Should I Use a Jib Crane in My Operations?

Adding jib cranes to production facilities and manufacturing environments can help you increase productivity, improve safety, and reduce workplace injury. These cranes easily add lifting and handling devices into areas where they are needed. Jib cranes are complimentary to your existing processes, helping streamline your processes to make both equipment and operators more efficient.

Jib cranes are flexible to meet a wide variety of needs in manufacturing and assembly operations. They can be outfitted with a wide range of lifting devices to meet your process needs like chain hoists and air balancers. Existing overhead crane systems in your facility allow for lifting and handling within a certain working envelope. Jib cranes can add additional capabilities to the area around existing cranes to make processes more effective, like adding in a small work cell or workstation area.

Just like adding any piece of lifting equipment, knowing your existing processes and your goals is the first step to determining what is needed. Once you know this, you can reach out to a crane manufacturer or crane dealer to talk about what types of products will fit your needs.

If you are looking for a way to add lifting capabilities into your tight floor plan or in an underutilized space within your production facility, a jib crane may be an option to explore. Well-known for its boom, a jib crane can be freestanding or wall-mounted to meet your unique needs. Adding a complimentary hoist and trolley will allow your operators to work within a work-cell area and minimize or eliminate manual lifting.

Learn more about Demag jib cranes and Demag DC Chain Hoists to help you optimize your operations. Reach out to us to discuss your upcoming project.