A lifting icon is here to stay and it’s expanding! The Demag DH wire rope hoist is known for its robust construction and fit for extreme applications. It’s found in galvanizing, precast concrete, and metals where high heat, contaminants, and moisture push all equipment to the max. Coming in 2024, an expansion of the existing model lineup.

More Than Lifting

Iconic for its lifting capabilities, the DH wire rope hoist is versatile and reliable to meet your lifting and stationery application requirements. In 2024, the lineup will expand to include the DH400 model for capacities from 1 to 10 tons. Along with the DH600, DH1000, and DH2000, this will allow for a full range of lifting up to 100 tons. But the DH is versatile for more than just lifting.

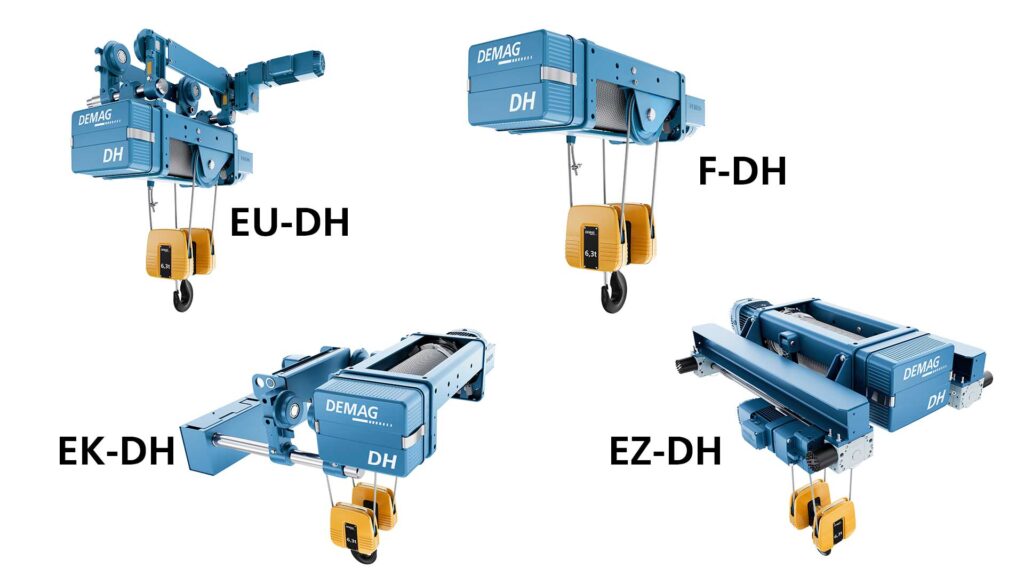

Lifting with the DH hoist can be matched to your requirements. On single girder crane and monorail applications, the underhung EU-DH and low headroom EK-DH allow for capacities up to 16 tons. The low headroom configuration has optimized hook lift dimensions. Double girder EZ-DH configurations handle the heaviest loads, up to 100 tons, with favorable approach dimensions and a flat design.

For the ultimate in flexibility, the foot mounted F-DH configuration can meet your requirements for stationery hoist and custom trolley applications up to 100 tons. The direct connection design allows the hoist to be attached on any of the four sides with rope leadoffs in virtually any direction.

Rugged Design Meets Updated Features

With the expansion of the product line, the DH hoist has updated features to meet a wider range of requirements. With inverter control now standard, you can choose inverter control or contactor control for the requirements of the project. Inverter control allows for smooth, variable speed lifting of the load. Paired with inverter control is the Demag ZBA motor manufactured in our plant in Uslar, Germany. Add intelligent control for DGS 4 geared limit switch, electronic load monitoring, and added smart features like slack rope functionality.

New to the DH hoist are bottom blocks with DIN-rated load hooks. Demag bottom blocks are ergonomic for operator use and include optional special reeving options for traversing winches, double hook, and multiple ropes.

Standard and Optional Features

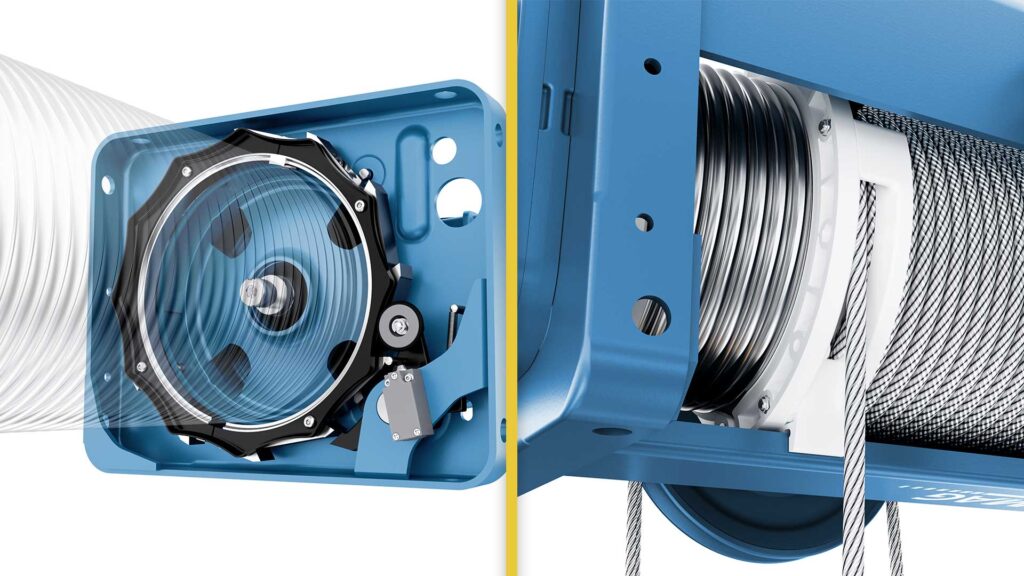

The rope guide on the DH wire rope hoist is made from acid-resistant plastic PA12 and can be changed without special tools by your service technician. As your project requires more, optional rope guides are available for applications requiring reinforced guides and frost proof.

For facilities requiring additional safety or load hold brake, the DH is equipped. The load hold brake, or safety brake, acts directly on the rope drum to meet requirements. If you’re replacing your DH or installing a new hoist, choose the optional Demag DST pendant or DRC radio option. Demag pendants and radios are ergonomic and reliable. Built to be rugged like the DH, these options are impact resistant and has options for protection against extreme environments and conditions.

Built with Demag Motors Made in our Ulsar Factory

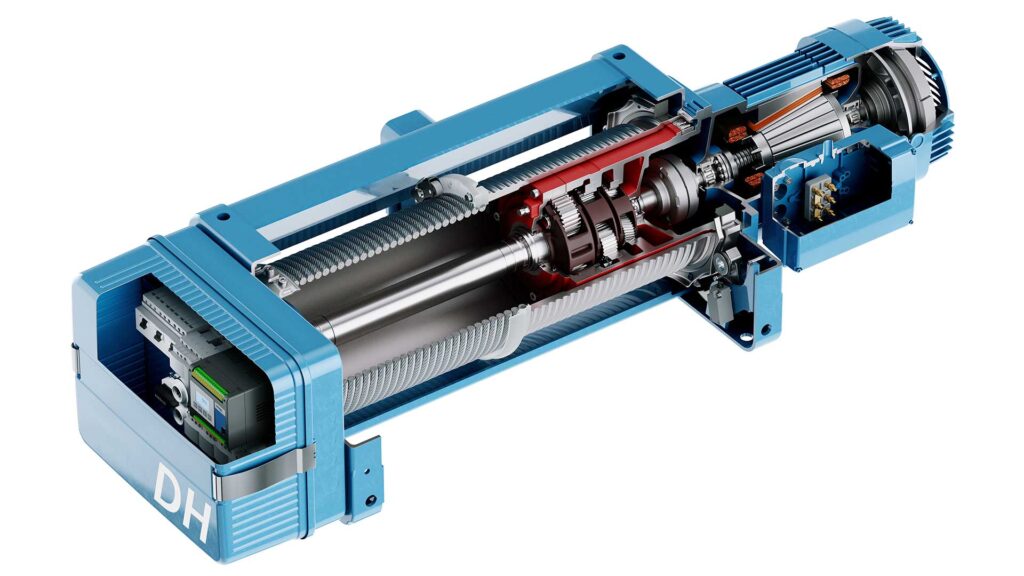

The reliable, robust motors and drives you trust are built into the DH wire rope hoist. No matter if you choose inverter control or contactor control, the drives are Demag motors. Inverter controlled hoists use the ZBA conical rotor brake motor. The inverter allows for motor temperature, adjustment, and brake release monitoring.

When high duty and a high number of starts and stops are required, Demag KB motors and the FG microspeed motor combination will meet your requirements. Choose between the F6 and F10 co-axial options.

Upgrading to the main and creep motors with pole-changing F6 gives 1:6 speed ratio with sliding-rotor motors with the integrated conical brake. This reliable and efficient option uses Demag KBH squirrel cage motors and includes motor temperature monitoring as standard.

For the ultimate precision, choose the F10 mechanical microspeed unit for 1:10 speed ratio. Using Demag Drive Technology, the motor combination includes the KBH and KBA squirrel cage motors as separate motors. The motors include mechanical braking with the conical rotor design.

The iconic Demag DH Wire Rope Hoist is more than lifting. It’s expansion to include the DH400 model for lifting 1-10 tons allows the hoist to be used in additional applications. With configurations to meet application requirements, this rugged, reliable hoist continues to deliver standard and optional features. You can be assured today’s DH hoist uses Demag motors made in our Uslar, Germany factory regardless of your control option.